Electric tool gear assembly assembling system

An electric tool and assembly assembly technology, applied in the direction of manufacturing tools, assembly machines, metal processing equipment, etc., can solve the problems of high assembly rework rate, low production efficiency, and inability to meet automation, so as to improve the degree of automation and save human resources , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Refer to attached picture.

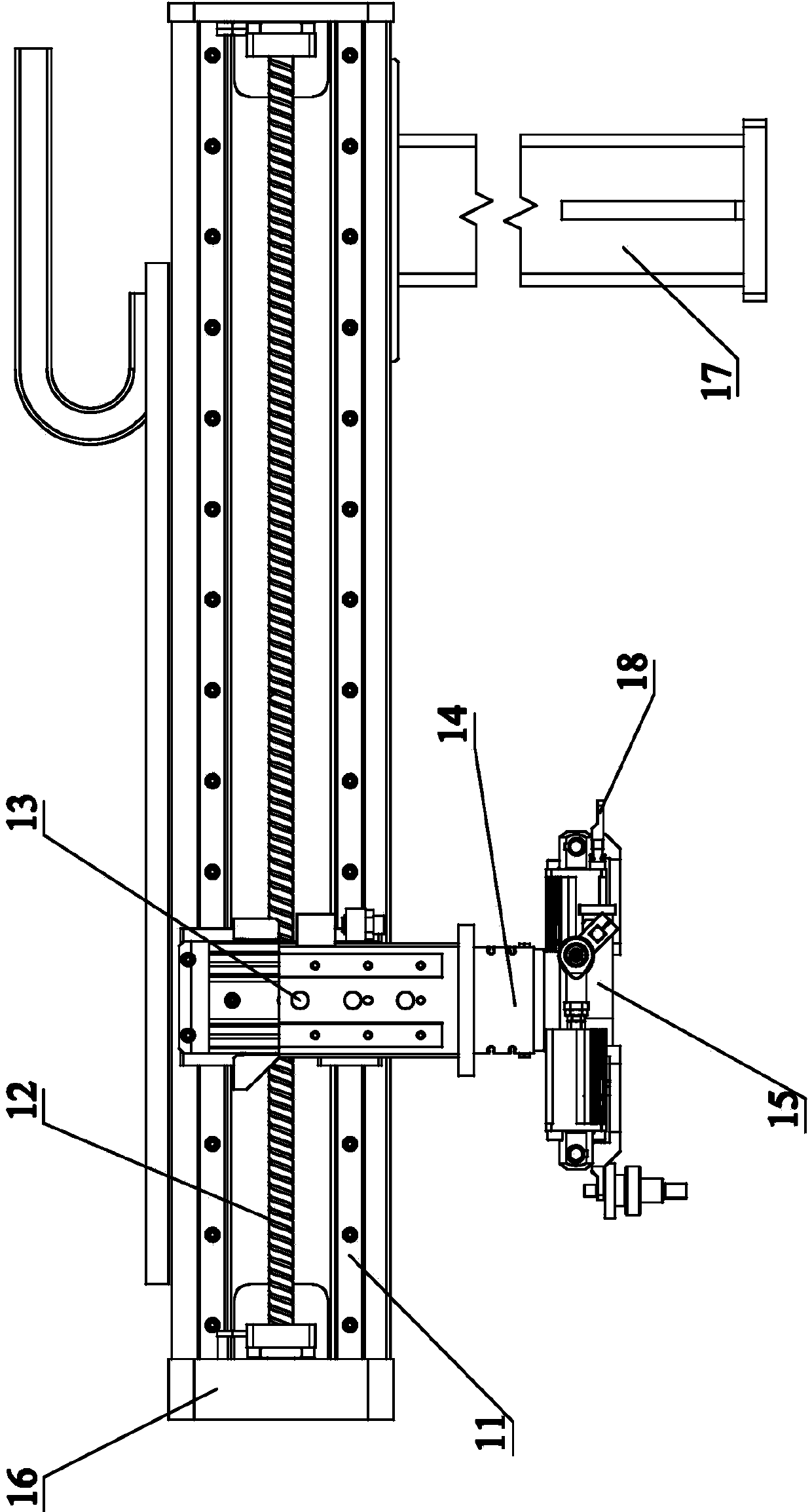

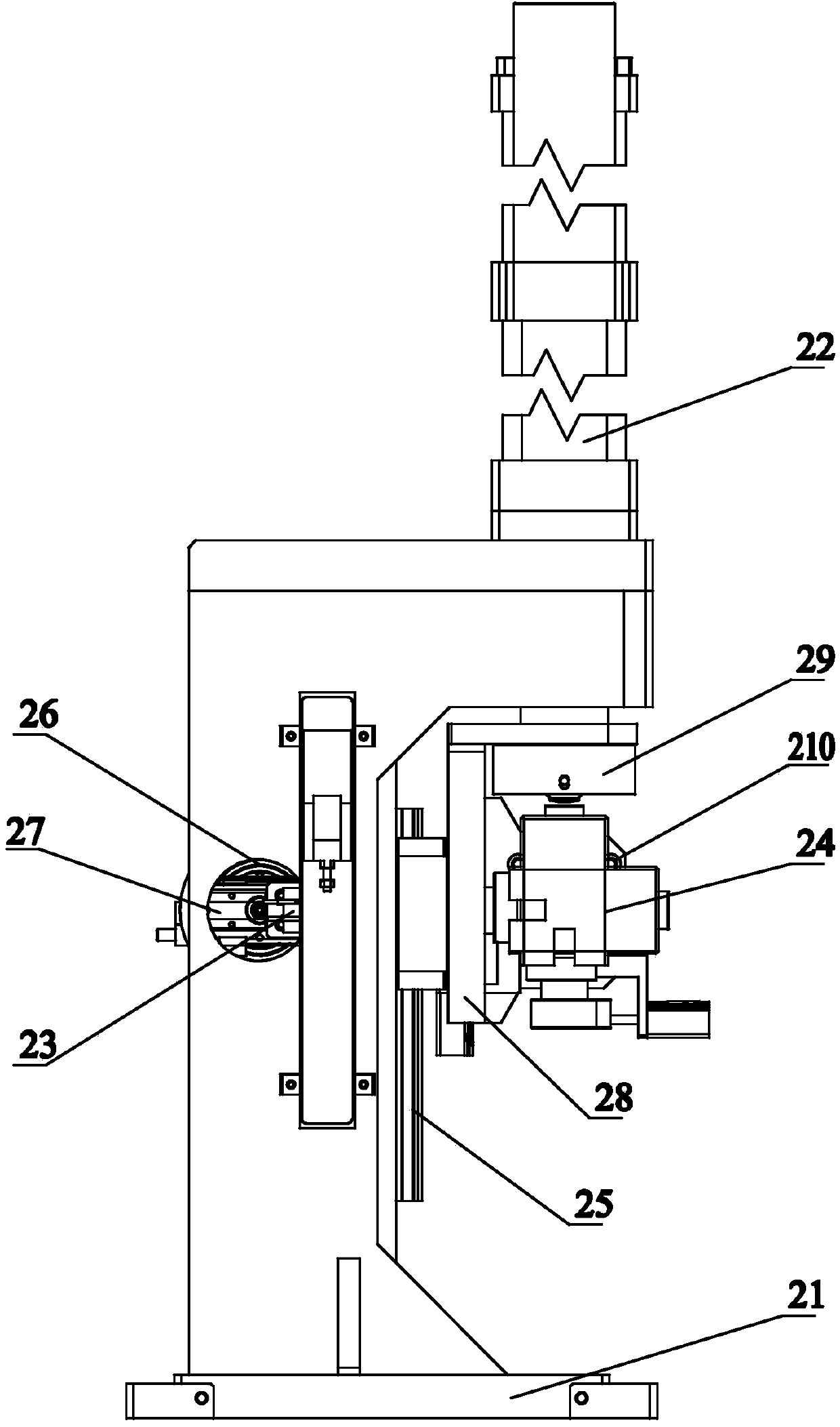

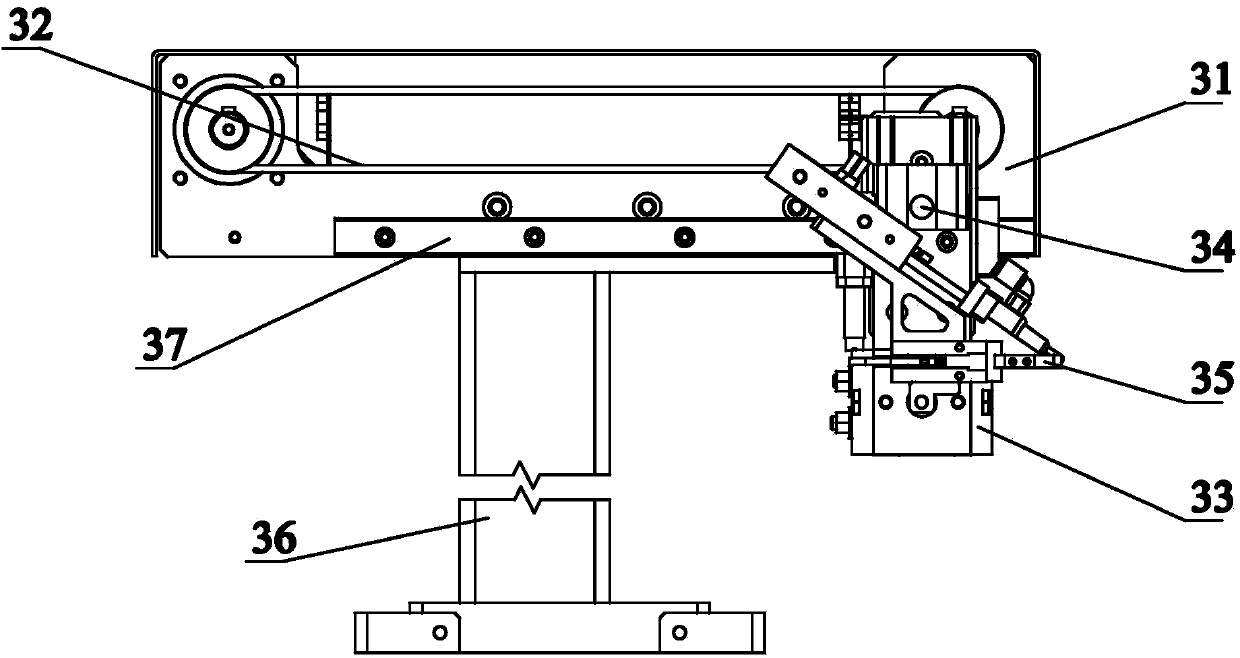

[0028]The electric tool gear assembly assembly system of the present invention includes a frame 100 on which a manipulator component 1, a bearing assembly component 2, a half-round key assembly component 3, a gear assembly component 4, a retaining ring assembly component 5, and a needle roller are installed. The bearing assembly part 6 and the workpiece indexing mechanism 7, wherein the manipulator part 1 is used to load the gear shaft in the gear assembly into the corresponding installation station of the workpiece indexing mechanism 7 to prepare for the next step of installation, and to remove and disassemble the completed parts Gear assembly, the bearing assembly part 2 is used to install the deep groove ball bearing in the gear assembly into the gear shaft, the half-round key assembly part 3 is used to install the half-round key in the gear assembly into the gear shaft, and the gear assembly part 4 is used For installing the gears in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com