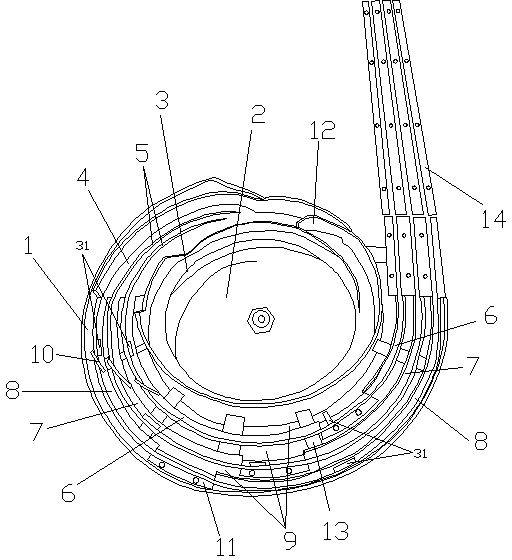

Three-rail vibrating plate

A vibrating plate and track technology, applied in the direction of vibrating conveyors, conveyor objects, conveyors, etc., can solve the problems of small size of iron core workpieces, rework, difficulties in manual feeding operations, etc., to reduce rework costs, improve feeding efficiency, The effect of improving the work intensity of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

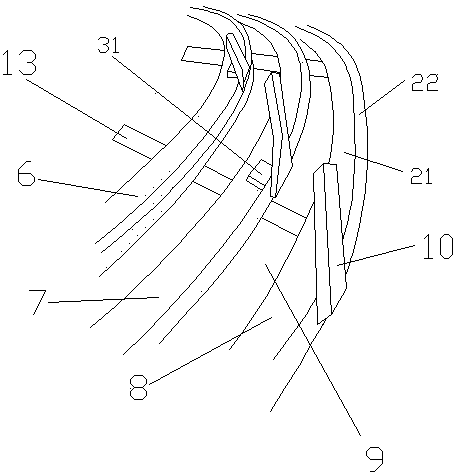

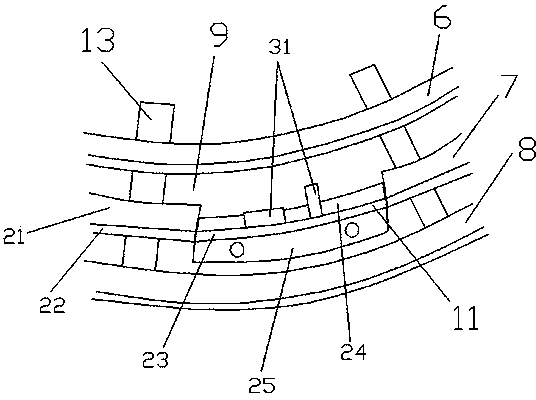

[0021] The specific embodiment is as follows: a large number of small and thin strip iron core workpieces 31 are put into the hopper 2, and the iron core workpieces 31 rise and advance through the inner spiral track 3, and the first baffle plate 12 of the discharge port 4 passes through the stacking The iron core workpiece 31 is divided into three strands by the two-layer ladder structure 5 at the outlet of the discharge port, and enters the first track 6, the second track 7, and the third track 8. Due to the shunting effect of the two-layer ladder structure 5, the iron core workpieces 31 in the first rail 6, the second rail 7, and the third rail 8 may be stacked or moved laterally, which will affect the conveying speed of the iron core workpieces 31, and post-grinding effects. To prevent stacking, the iron core workpiece 31 will first pass through the anti-stacking baffle 10, so that the stacked or erected iron core workpiece 31 cannot pass through the height limited by the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com