A method for online detection of blast furnace slag output

A detection method and technology for slag production, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problem of not being able to timely reflect the real-time status of blast furnace tapping and slagging, unfavorable for refined, intelligent and standardized operation of blast furnace production, and inability to effectively detect Blast furnace slag output and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited.

[0029] An online detection method of blast furnace slag output based on the present invention has been tested on a blast furnace. The blast furnace ironmaking production process and equipment are various, and the slag treatment system belongs to its peripheral auxiliary equipment. The two-level communication of the blast furnace L1 and L2 transmits the current signal of the water slag dehydration drum inverter to the blast furnace process computer system for subsequent calculation and display. Furnace chief ensures the smooth and smooth operation of the blast furnace and provides a reliable basis for judgment.

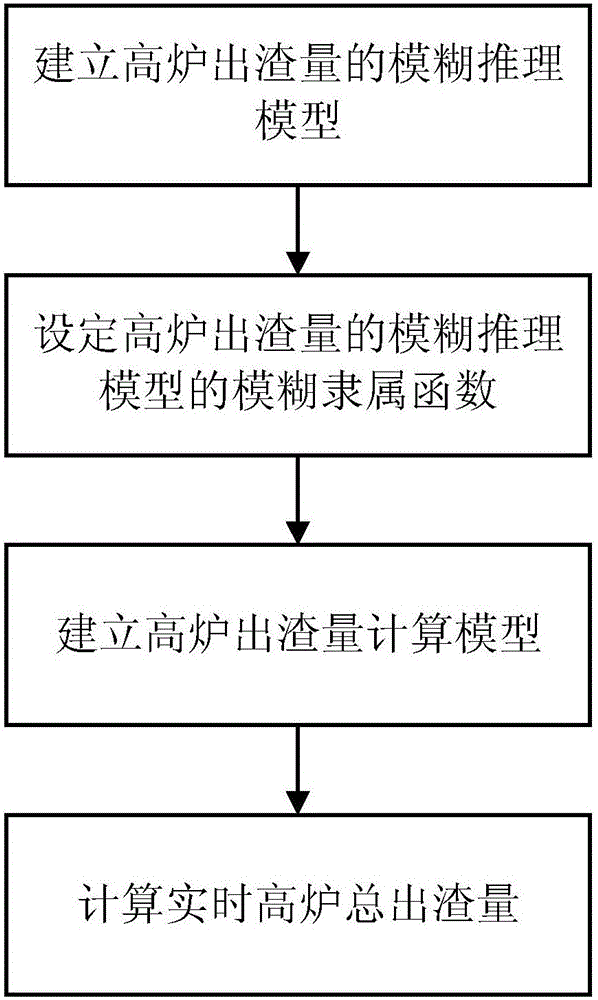

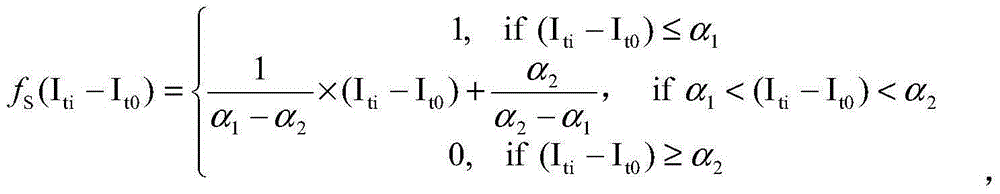

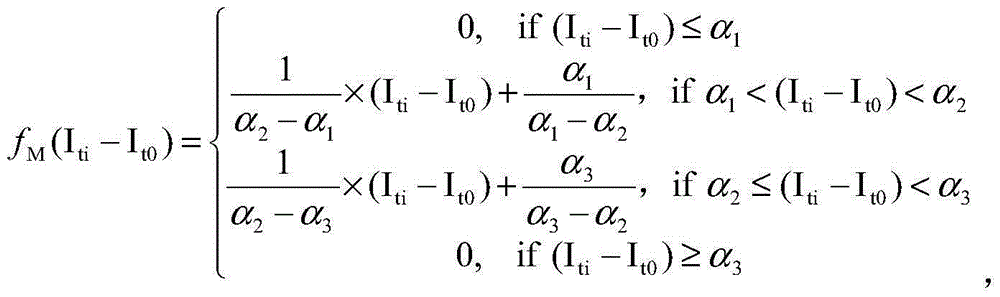

[0030] figure 1 The flow chart of on-line detection of blast furnace slag output by the method of the present invention is given. based on figure 1 , the specific calculation process of the flatness s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com