Method for predicting martensite structure evolution in high-strength plastic product steel quenching

A high-strength plastic product, martensitic transformation technology, applied in the field of steel rolling, can solve the problems of low efficiency, material and financial resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

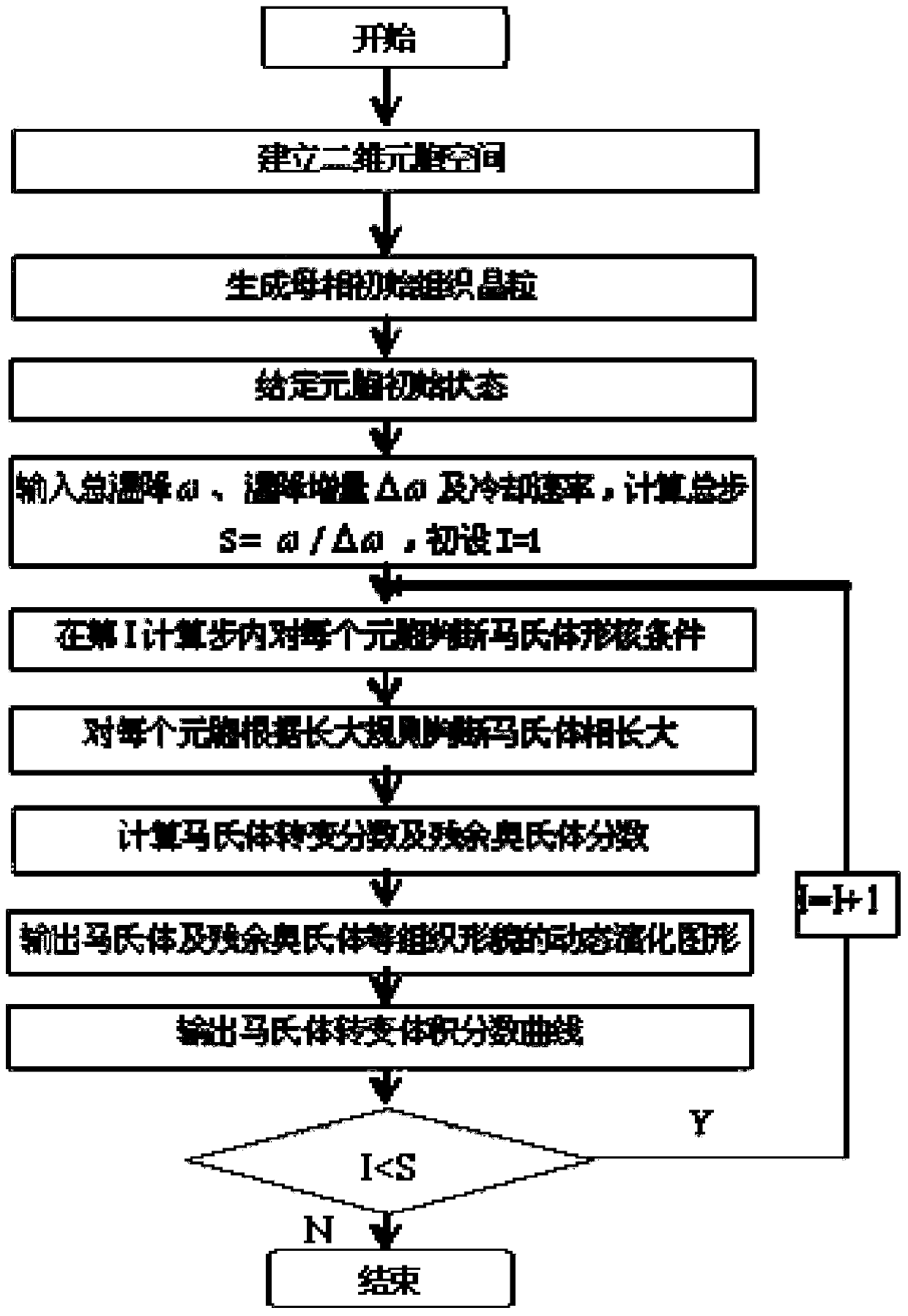

[0065] The process flow of the method for predicting the evolution of martensitic structure in the quenching of high-strength plastic product steel in the present invention is as follows figure 1 As shown, the steps are:

[0066] 1. Start;

[0067] 2. Establish a two-dimensional cell space;

[0068] 3. Generate the initial grain of the parent phase;

[0069] 4. Given the initial state of the cell;

[0070] The model assigns each cell 4 state variables:

[0071] (a) Carbon content variable, the initial carbon content of the cell is the mole fraction of the carbon content in the high-strength plastic product steel;

[0072] (b) Orientation variable. Randomly take a number between 1 and 180 as the orientation value for the newly generated martensite cell, and point out the martensite bundle it belongs to. Those with the same orientation value belong to the same martensite bundle. The martensite bundles correspond to different colors;

[0073] (c) Phase transformation flag v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com