Glass substrate support used for vacuum coating, film coating system thereof, and conveying method of the film coating system

A glass substrate and vacuum coating technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve problems such as damage, coating shadow, coating defect glass substrate, etc., achieve stable transmission, simple structure, Solve the effect of coating shadow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

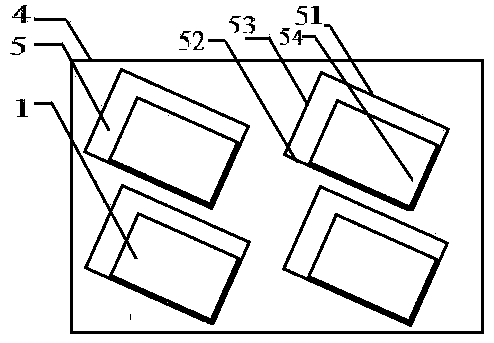

[0024] figure 1 Shown is a front view of a prior art glass substrate fixing jig. The glass substrate 1 is placed on a carrier device 2 and fixed around it with several clamps 3 . During the vacuum coating process, especially the sputtering coating, the glass substrate 1 is in a state of vibration, and the carrying device 2 becomes loose due to long-term clamping and impact with the fixture 3, and the glass substrate 1 is easily broken. Moreover, the unstable supporting force of the fixture will cause uneven coating of the glass substrate; the fixture has accumulated a certain thickness of film due to long-term use. Yield rate after coating.

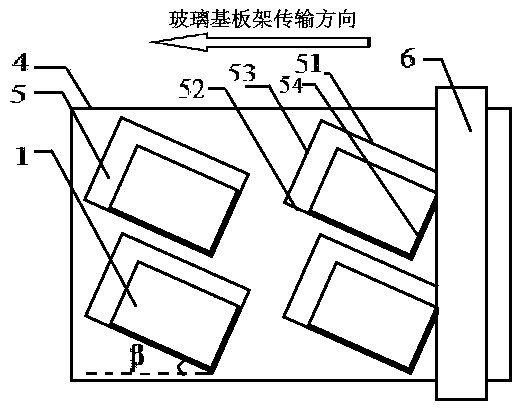

[0025] Therefore, the present invention designs a glass substrate rack 4 that does not require the use of clamps, aiming at the negative effects brought about by the clamps for fixing the glass substrates. figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com