Flat plate type sunlight leading-in lighting system

A lighting system, a flat-panel technology, applied to lighting devices, using sunlight, non-electric lighting devices, etc., can solve the problems of clumsy size of the reserved squat seat, easy condensation, and reduced lighting efficiency, achieving excellent heat preservation effect, Improved safety factor and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

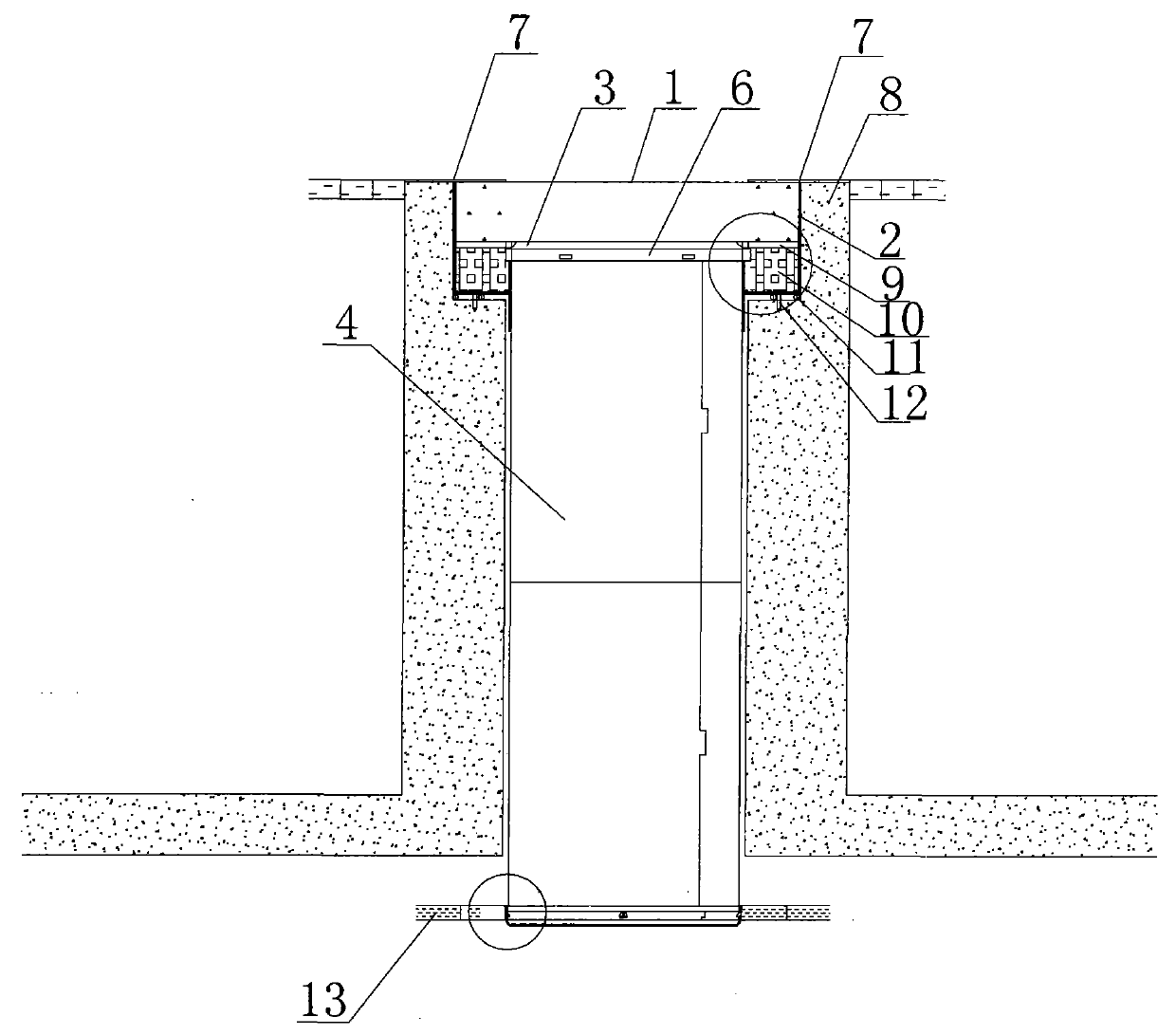

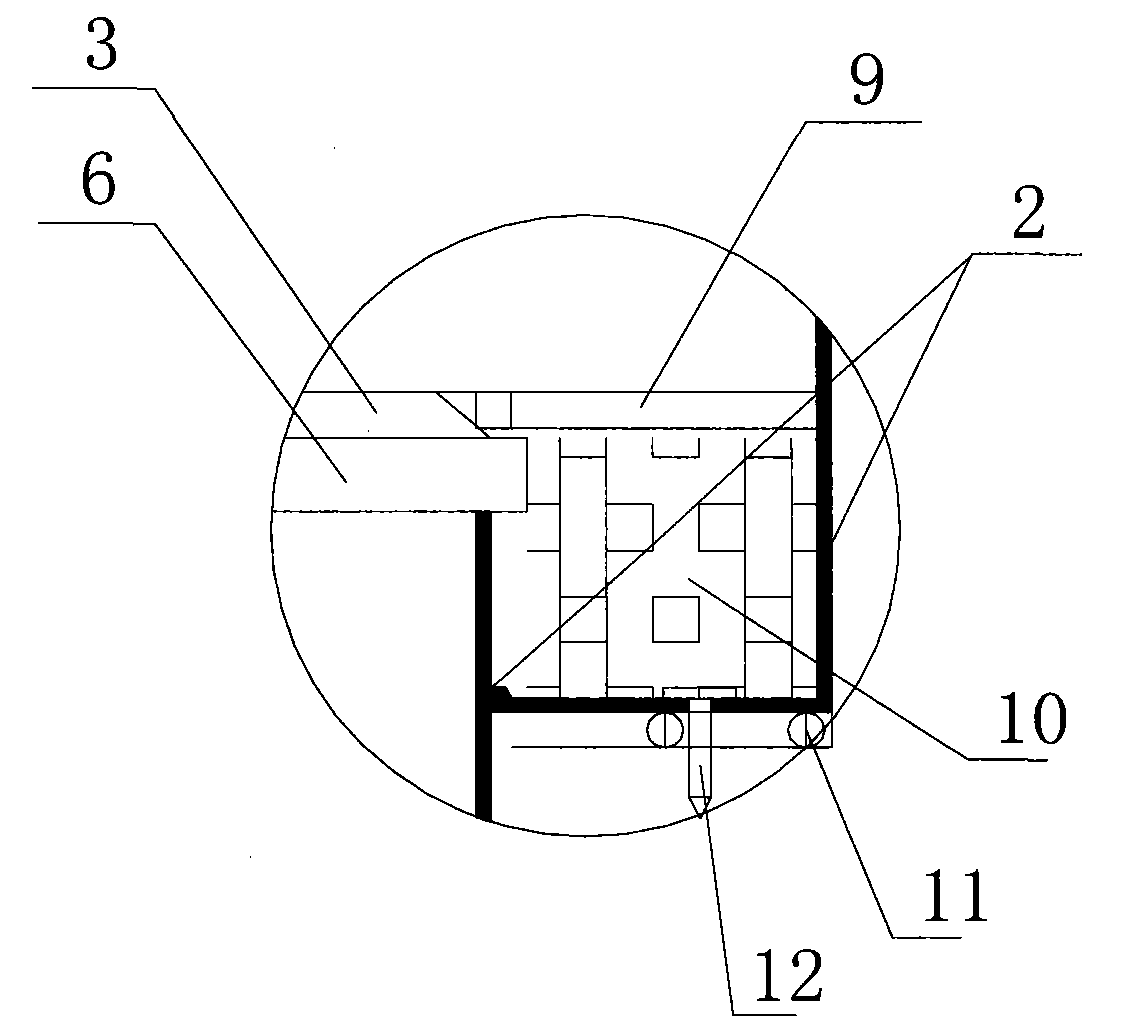

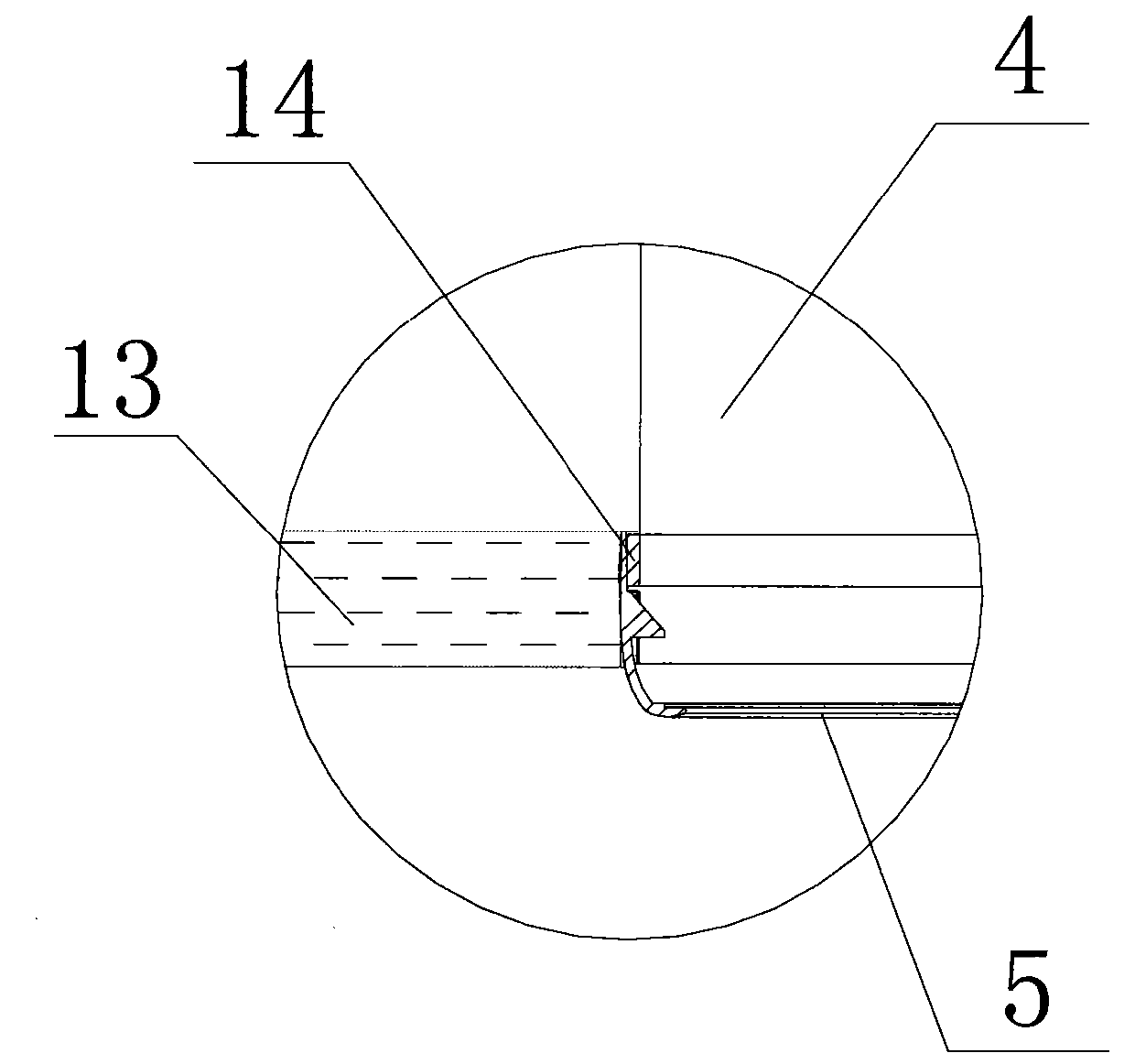

[0022] As shown in the figure, the present invention is a flat-type daylight introduction lighting system, which includes a flat-type lighting cover 1, a flat waterproof cap 2, a light-catching reflection sheet 3, a light guide tube 4 and a diffusion device 5. The flat-type lighting The cover 1 is installed on the flat waterproof cap 2, the light catching reflection sheet 3 is installed on the periphery of the flat daylighting cover 1, and one end of the light pipe 4 is fixed below the light catching reflection sheet 3 by the light pipe fixing ring 6, The diffusion device 5 is installed at the other end of the light guide 4;

[0023] The flat waterproof cap 2 is provided with a humidity reactant storage tank 10, and the humidity reactant storage tank 10 is equipped with condensation filling for the anti-lighting cover; the condensation filling means that there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com