A substrate drying device and substrate drying method

A drying device and substrate technology, applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve problems such as shedding, lower product yield, substrate defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

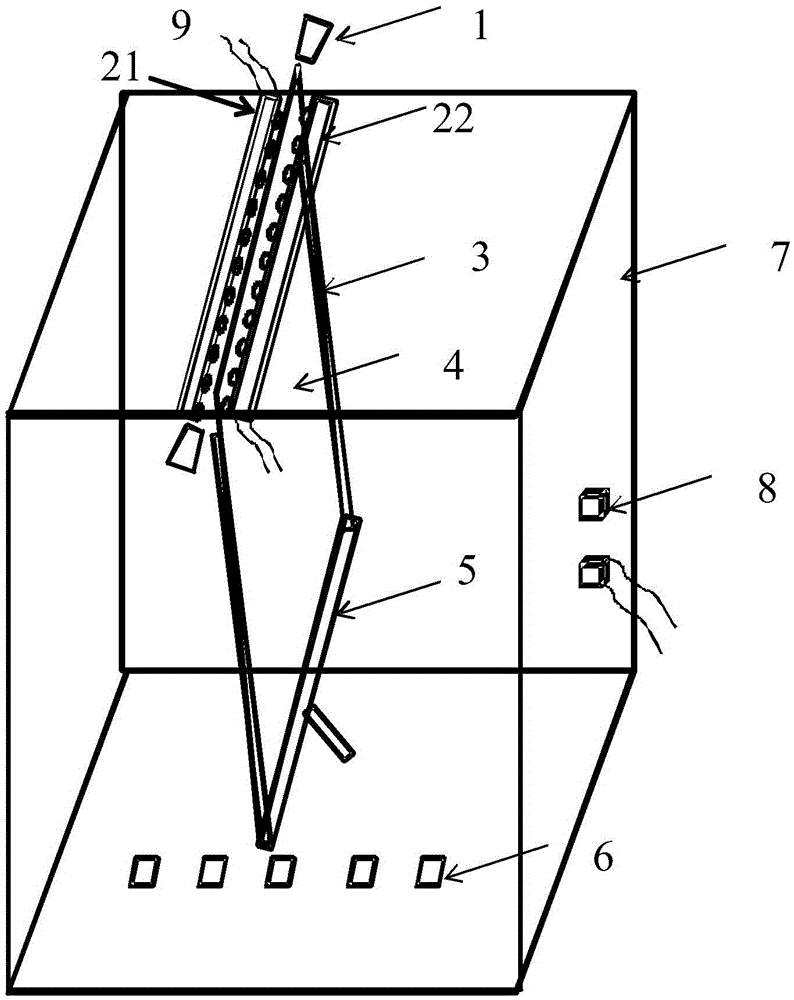

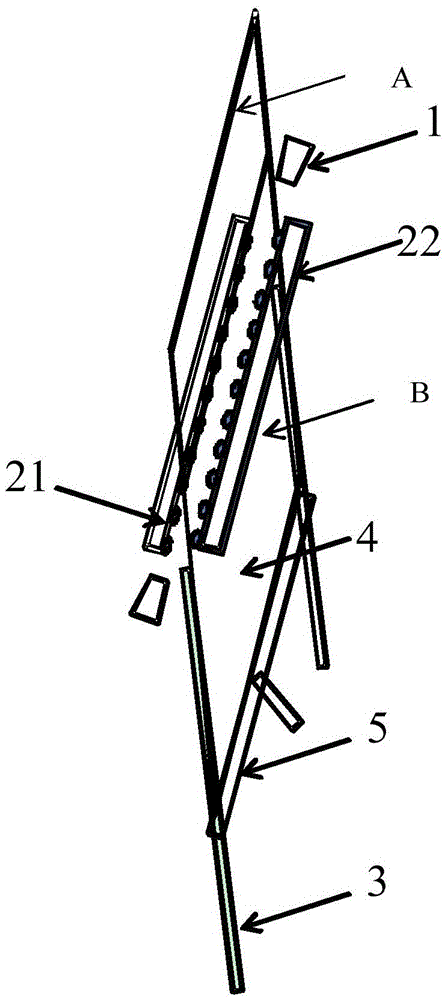

[0032] Embodiment 1 of the present invention provides a substrate 4 drying device, the structure diagram is as follows figure 1 As shown, it includes a cavity 7 and a drying rod and an inductor 1 arranged on the top of the cavity 7 , the cavity 7 is filled with a liquid for immersing the substrate 4 .

[0033] The drying bar dries the substrate 4 leaving the liquid, including a first drying bar 21 and a second drying bar 22 arranged in parallel, with a gap between the first drying bar 21 and the second drying bar 22, and one or both ends of the gap are arranged There is a sensor 1 for monitoring the position of the substrate 4 away from the liquid.

[0034] The substrate drying device improves the structure of the existing substrate drying device, no longer uses the air knife to directly dry the substrate surface, and monitors the position where the substrate leaves the liquid through the sensor. The gas ejected from the drying rod on the side dries the substrate to avoid def...

Embodiment 2

[0046] Based on the above, Embodiment 2 of the present invention also provides a method for drying a substrate based on the substrate drying device described in Embodiment 1, which specifically includes:

[0047] The substrate gradually leaves the liquid under the thrust force. When the sensor senses that the substrate leaves the liquid, the first drying rod and the second drying rod located on both sides of the substrate spray gas to the surface of the substrate. At the same time, the substrate continues to leave the liquid under the thrust. Under the action of gas, the Marangoni effect is used to change the surface tension of the liquid film on the substrate, and the surface tension gradient of the liquid film shrinks the liquid film to realize the drying of the substrate surface.

[0048] Further, when the sensor senses that the substrate is completely separated from the liquid, the ejection of gas is stopped.

[0049] Based on the above, the schematic diagram of the drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com