Sound-seismic coupling efficiency measuring device and measuring method

A coupling efficiency and measurement device technology, applied in the field of geophysical prospecting, can solve the problems of non-contact detection of surface vibration velocity, inability to achieve high directivity, long-distance sound wave emission, etc., and achieve the effect of improving system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

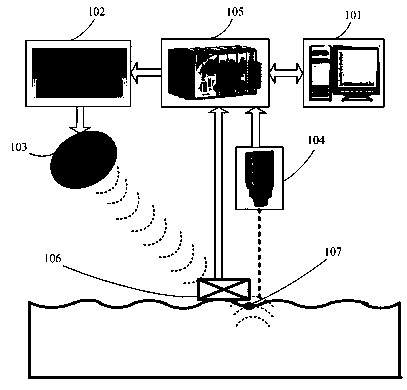

[0021] Embodiment one: see figure 1 The structure of the local surface acoustic-seismic coupling efficiency non-contact measurement device includes a computer 101, a signal processor 102, an acoustic parameter array 103, a Doppler vibrometer 104, a data acquisition card 105 and a sound level meter 106, and the computer 101 is sequentially Connect the data acquisition card 105, the signal processor 102 and the acoustic parameter array 103 through a data line to form an acoustic emission system; The computer 101 constitutes a sound pressure level detection system; the Doppler vibrometer 104 is sequentially connected to the data acquisition card 105 and the computer 101 through a data line to constitute a surface vibration detection system.

[0022] The acoustic parameter array 103 and the signal processor 102 used in this embodiment adopt the 24-in diameter Audio Spotlight ultrasonic transducer array (24-in diameter Audio Spotlight ultrasonic transducer array) produced by the Am...

Embodiment 2

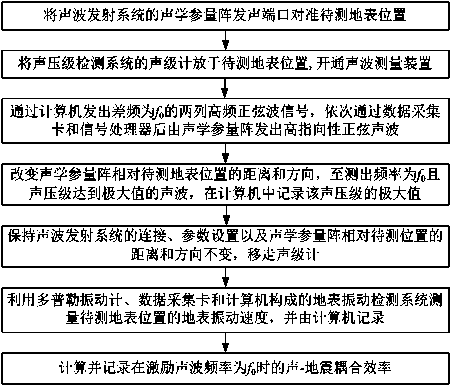

[0023] Embodiment two: see figure 2 , the local surface acoustic-seismic coupling efficiency non-contact measurement method, adopting the device of embodiment one to measure and calculate the surface acoustic-seismic coupling efficiency, the measurement steps are as follows:

[0024] (1) Align the sounding port of the acoustic parameter array 103 of the sound wave emission system with the surface position 107 to be measured;

[0025] (2) Place the sound level meter 106 of the sound pressure level detection system at the position 107 on the ground surface to be measured;

[0026] (3) The difference frequency sent by the computer 101 is f 0 The two columns of high-frequency sine wave signals pass through the data acquisition card 105 and the signal processor 102 in turn, and the acoustic parameter array 103 sends out a high-directivity sine wave;

[0027] (4) Change the distance and direction of the acoustic parameter array 103 relative to the surface location 107 to be meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com