A Ytterbium-Doped All-Fiber Optical Frequency Comb System

An optical frequency comb and all-fiber technology, which is applied in optics, nonlinear optics, lasers, etc., can solve problems such as the inability to realize all-fiber design, and achieve the effects of improving stability and portability and reducing dispersion control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

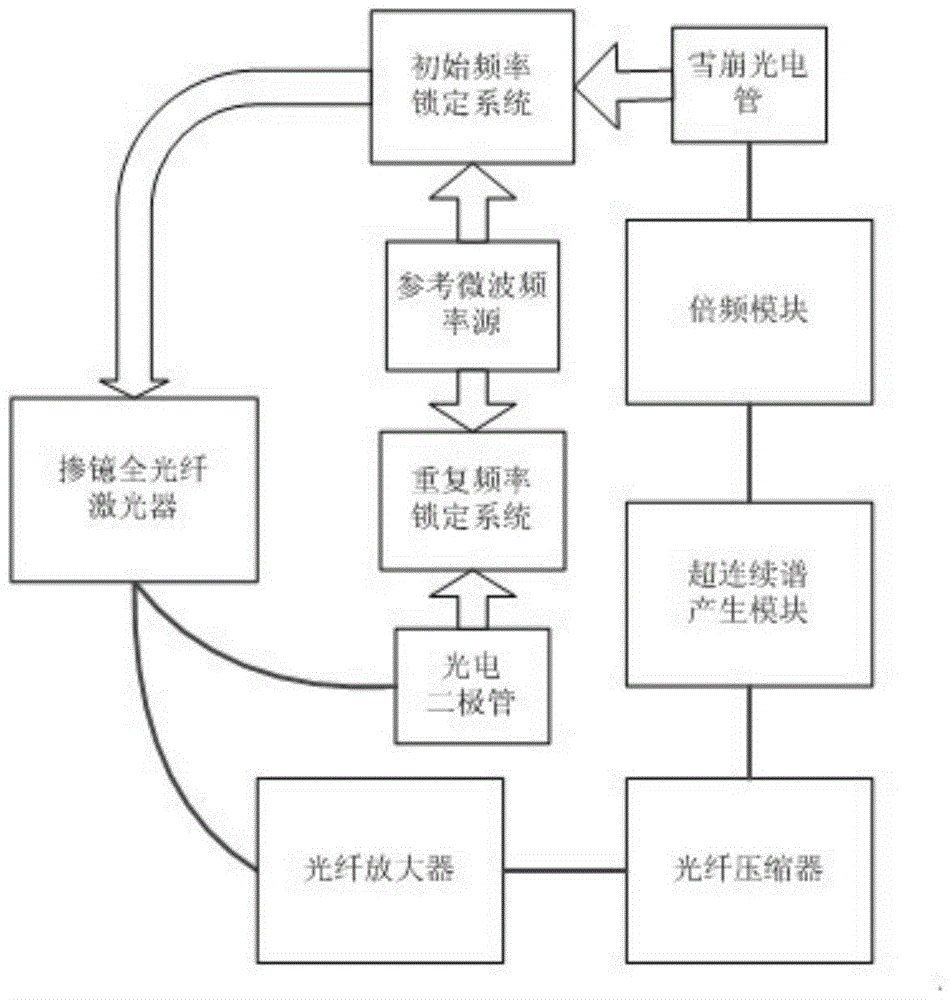

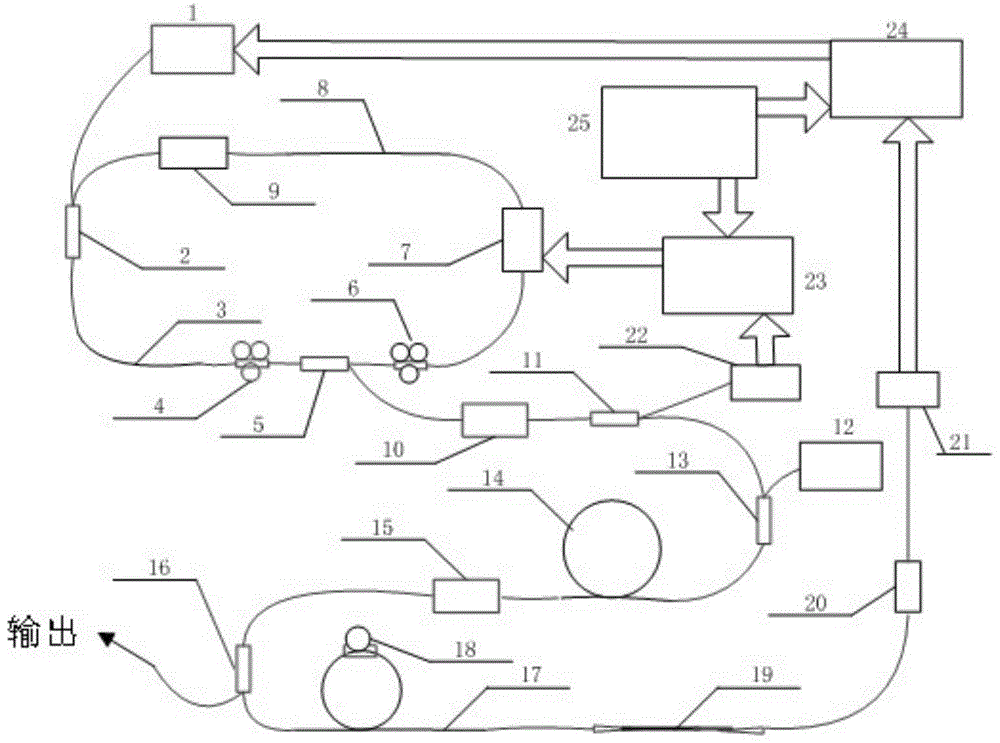

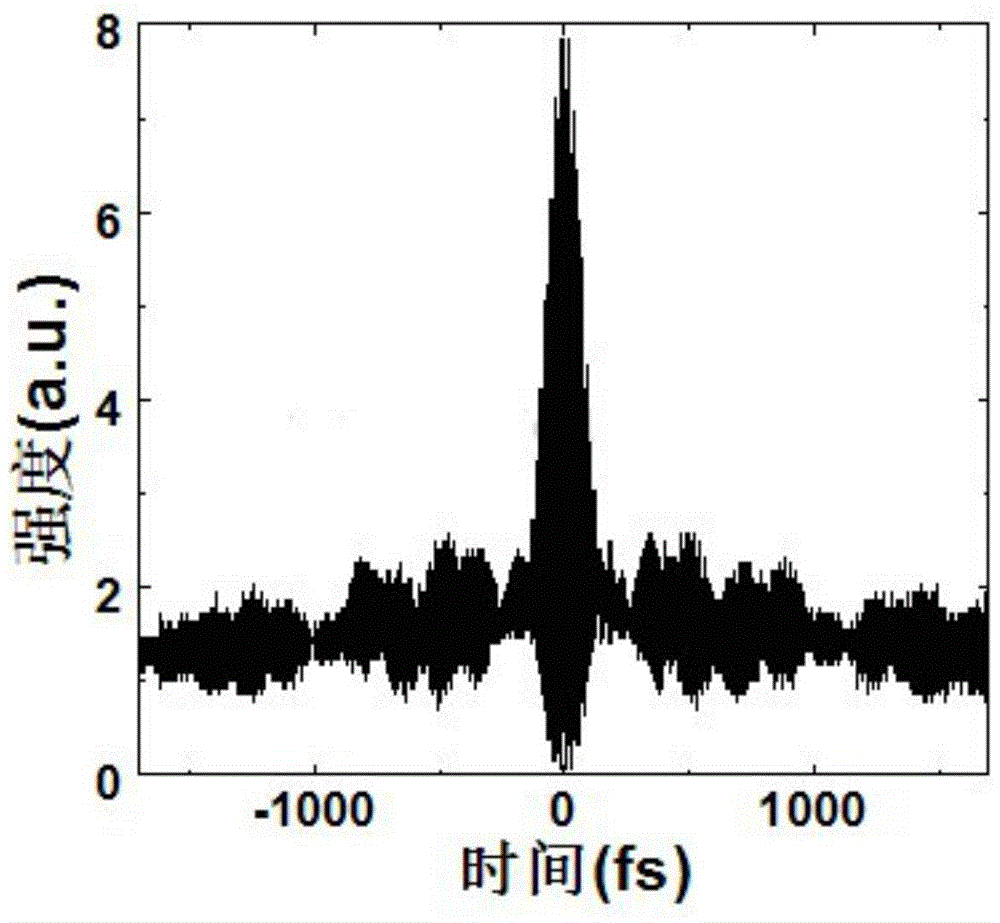

[0026] The embodiment of the present invention provides an ytterbium-doped all-fiber optical frequency comb system. The present invention uses the ytterbium-doped all-fiber ring cavity mode-locked laser as the source, and utilizes the first bandgap photonic crystal fiber and the second photonic crystal fiber with special properties And the tapered photonic crystal fiber solves the problem of dispersion compensation and the generation of octave-band supercontinuum, and adopts the low-loss welding method of photonic crystal fiber and ordinary fiber to realize the full fiber optic and integration of the whole system. The optical frequency comb system consists of an optical syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com