Drive axle dynamic characteristic computing method considering input torque changing

A bridge dynamics and characteristic calculation technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problem of not considering the influence of the bearing stiffness by the change of the input torque of the drive axle, and unable to reflect the influence of the change of the input torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

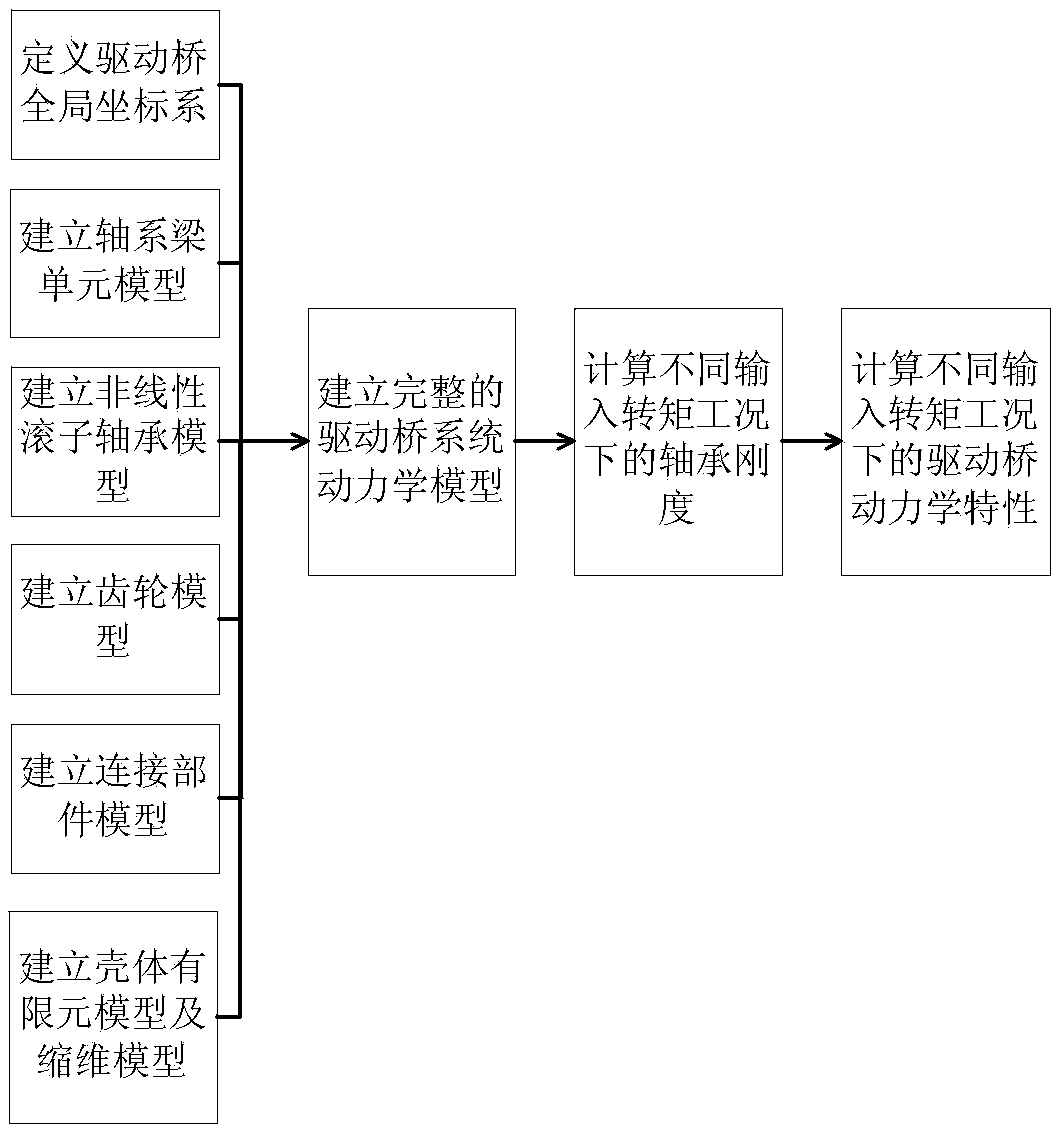

[0051] Such as figure 1 As shown, the calculation method of the dynamic characteristics of the drive axle considering the input torque variation provided by the present invention includes the following steps:

[0052] 1) Define the global coordinate system of the driving axle: define the global coordinate system of the driving axle system as the basis of system modeling.

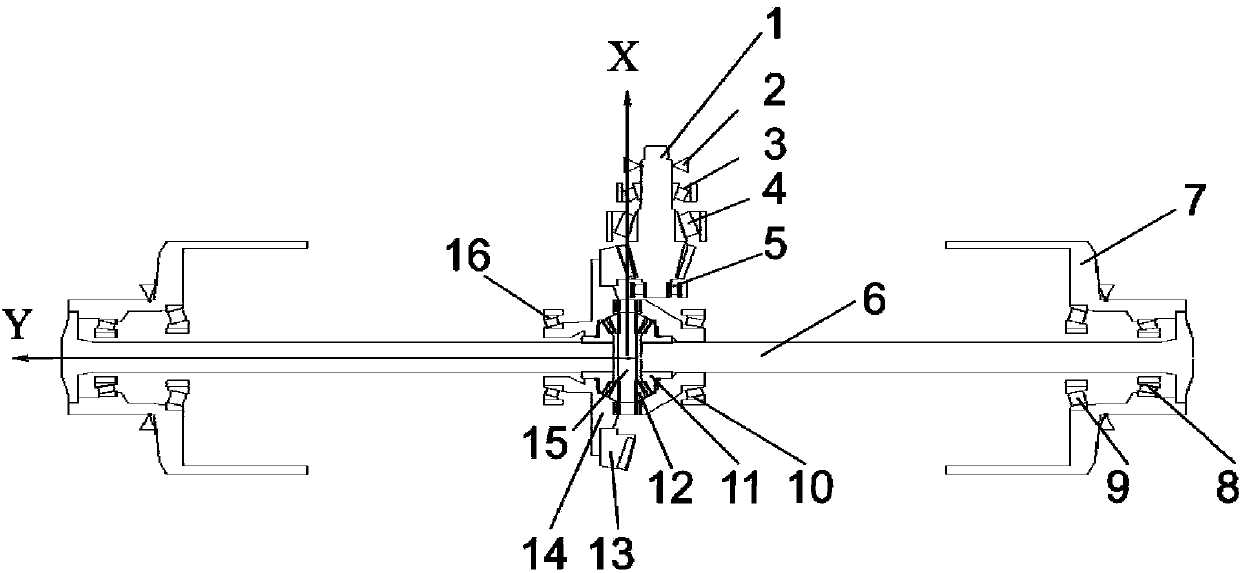

[0053] In this embodiment, the vehicle coordinate system of the car is used as the global coordinate system of the system, that is, the front of the vehicle is the positive direction of the x-axis, the left side is the positive direction of the y-axis, the vertical direction is the positive direction of the z-axis, and the origin of the coordinates is the differential speed the center position of the cross axis.

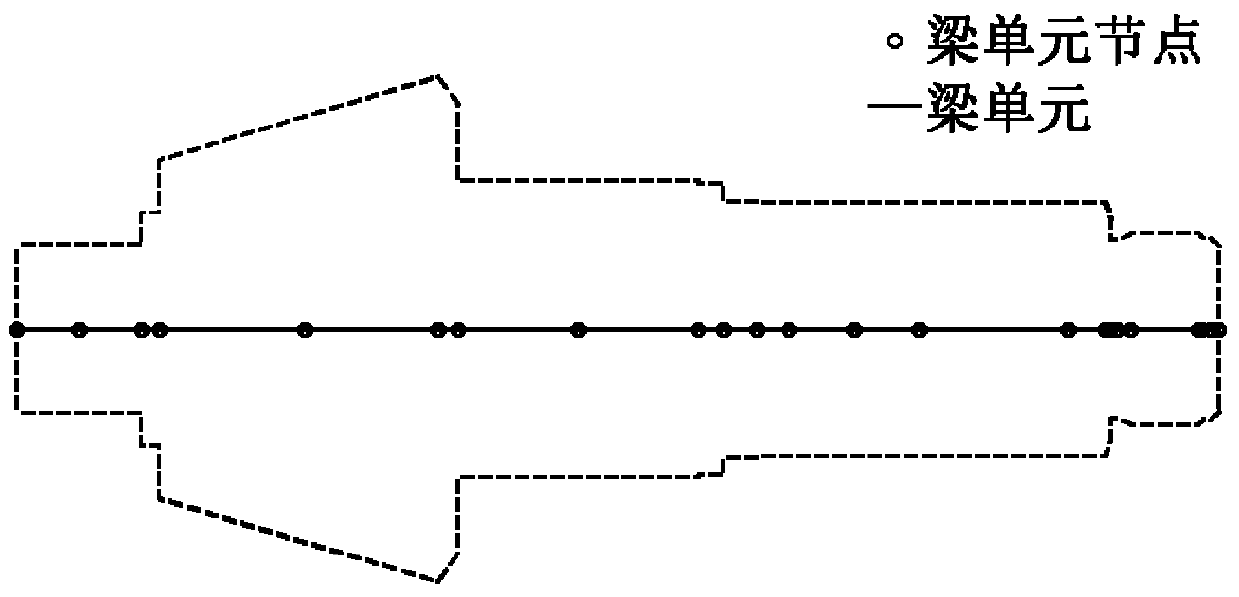

[0054] 2) Establish the shafting beam element model: the shafting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com