Preform extrusion molding apparatus, method for extrusion molding, and preform

A technology of injection molding and preforms, which is applied in the direction of lining/inner coating, coating, household appliances, etc., and can solve problems such as unstable dimensions, poor truncation, and unstable formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Hereinafter, the preform, the injection molding apparatus, and the injection molding method of the present invention will be described based on examples with reference to the drawings.

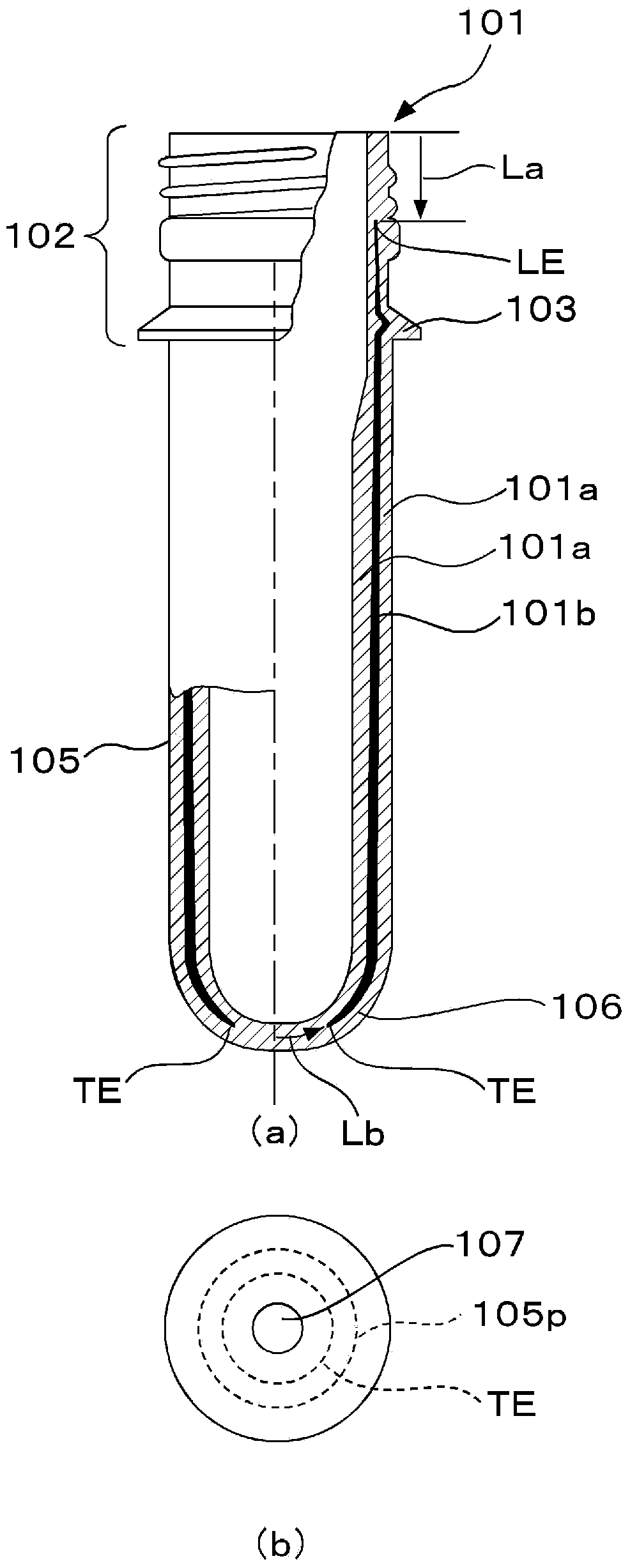

[0092] figure 1 An example of the preform 101 of the present invention molded by the injection molding method of the present invention described later is shown. 101a has a barrier resin layer 101b as a second resin layer as an intermediate layer.

[0093] In addition, in this example, nylon MXD6 was used as the barrier resin.

[0094] The preform 101 has an overall height of 100 mm, an outer diameter of the body portion 105 of 20 mm, an average thickness of the peripheral wall of the body portion 105 of 2.5 mm, and a weight of 22 g.

[0095] In addition, in the center of the outer peripheral surface of the bottom 106, a circular gate trace 107 with a diameter of 5 mm remains and is formed (refer to figure 1 (b)).

[0096] In addition, the front edge LE called leading edge (leading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com