Polytetrafluoroethylene microporous composite membrane haze prevention mask

A polytetrafluoroethylene and microporous technology, applied in the field of daily necessities, can solve the problems of no anti-haze effect, not suitable for public anti-haze use, poor filtration efficiency of fine particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 A kind of anti-haze mouth mask of polytetrafluoroethylene (PTFE) microporous lamination film

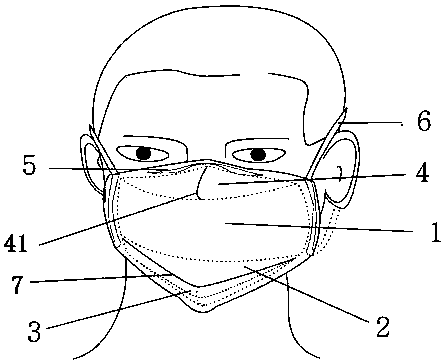

[0058] See figure 1 , 2 , 7, 8. A polytetrafluoroethylene (PTFE) microporous laminated film anti-haze mouth mask, it comprises: cover body, ear band 6, and cover body comprises body and lower side body 3, and described body and lower side body 3 comprise outer skin , the inner layer and the middle layer; the outer layer, the inner layer and the middle layer are wrapped and sealed;

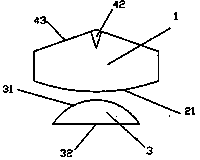

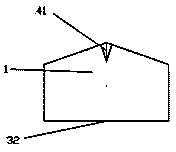

[0059] The body of the outer layer and the inner layer is divided into an upper part 4, a middle part 1 and a lower part 2. The upper edge 43 of the upper part 4 is triangular or arc-shaped, and is provided with a nose dart 41. The nose dart 41 is sealed after cutting off the margin 42 The lower part 2 and the lower body 3 are bow-shaped, the chord length of the lower body 3 is shorter than the chord length of the lower part 2, and the lower arc edge 21 corresponds to the lower body...

Embodiment 2

[0065] Embodiment 2 A kind of preparation method of polytetrafluoroethylene (PTFE) microporous lamination film anti-haze mouth mask

[0066] See Figure 1-8 , a method for making polytetrafluoroethylene (PTFE) microporous laminated film anti-haze mask, which comprises:

[0067] 1) Fabrication of outer and inner layers

[0068] A. Cutting

[0069] The main body is 230mm wide, the upper part 4 is an isosceles triangle with a height of 40mm, the lower part 2 is a bow-shaped arch with a height of 20mm, and the distance from the upper apex to the lower apex is 115mm;

[0070] The lower body 3 is bow-shaped with a chord length of 160 mm and an arch height of 45 mm;

[0071] B. Cut off the 20mm wide and 35mm high prismatic allowance 42 at the top of the upper part 4, and seal the nose province 41;

[0072] Seal the lower arc edge 21 of the lower part 2 and the front edge (arc edge) 31 of the lower body to form the sealing part 7; the margin of the arc edge 21 is evenly reserved a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com