Metal liquid filling type flow regime viewer

An observer and molten metal technology, applied in the field of molten metal filling fluid state observer, can solve problems such as shrinkage porosity, cold insulation, sand sticking, etc., and achieve the effects of avoiding casting defects, optimizing the gating system, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

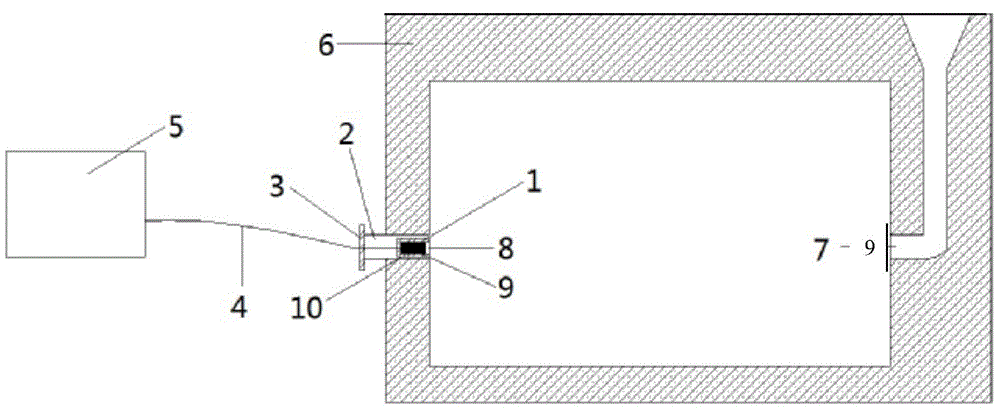

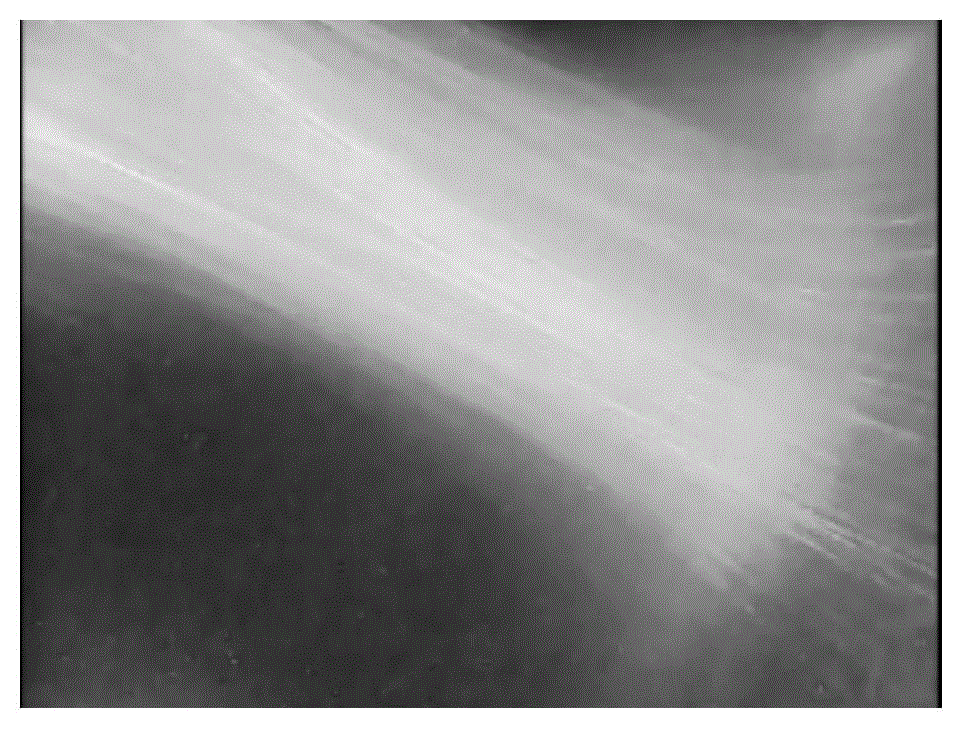

[0026] Example 1 Metal Liquid Filled Flow State Observer

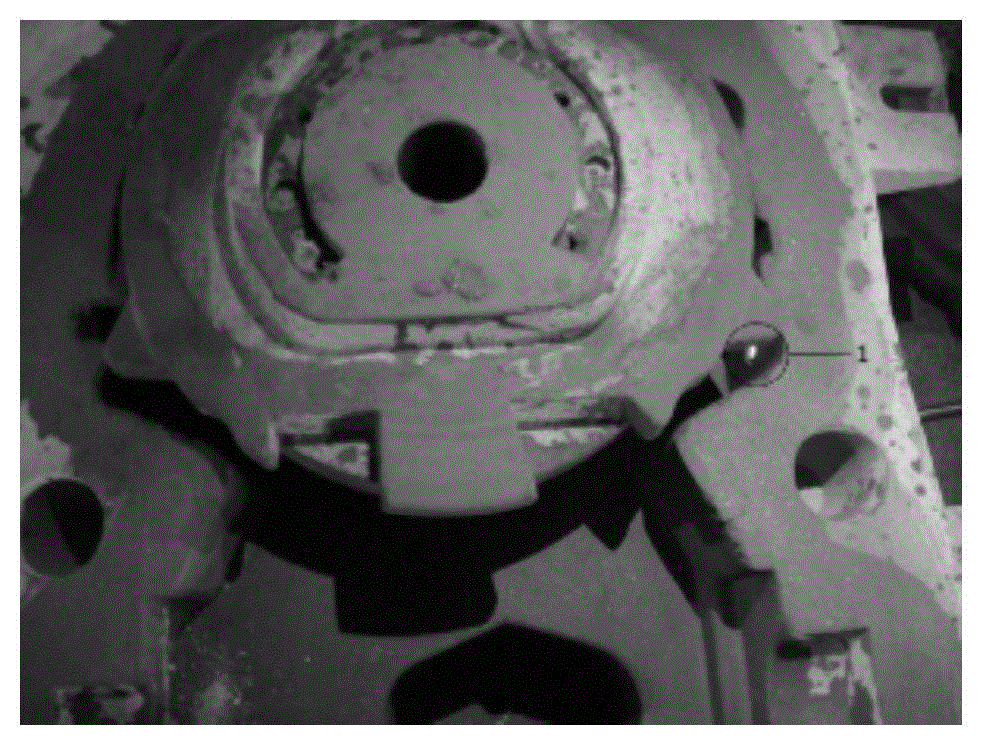

[0027] A metal liquid filled flow state observer is characterized in that the observer is composed of an endoscope 1, a steel pipe 2, a limit clip 3, a signal transmission line 4, a computer 5 and a casting mold 6, wherein the endoscope 1 is set In the steel pipe 2, the steel pipe 2 is pre-embedded in the mold 6, the limit clip 3 is clamped on one end of the steel pipe 2, one end of the signal transmission line 4 passes through the limit clip 3 and is connected to the endoscope 1, and the other end is connected to the computer 5 connected.

[0028] The said metal liquid filled flow state observer is characterized in that said endoscope 1 consists of a mirror glass 8 and an endoscope probe 9 . The endoscope 1 is placed within a sheath 10 .

[0029] Said a kind of liquid metal filling type flow state observer is characterized in that said steel pipe 2 is pre-embedded in the mold 6, the inner diameter of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com