Rotational casting mold chain and metallurgy casting machine with same

A technology of casting molds and molding machines, which is applied in mechanical cleaning, manufacturing tools, casting equipment, etc., can solve problems such as warped seams, limit the service life of molds, and burnt molds, so as to improve service life and ensure safe, continuous and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

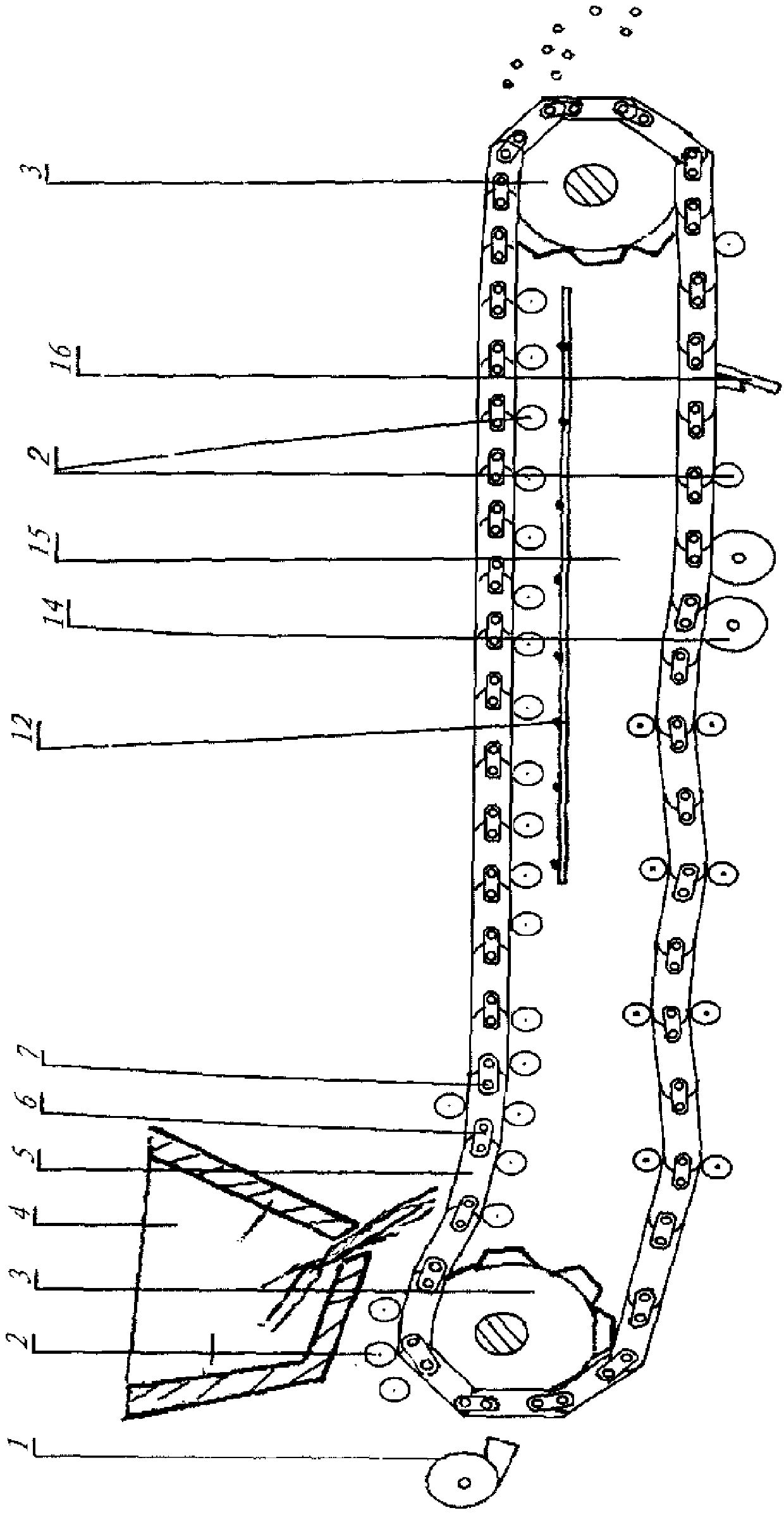

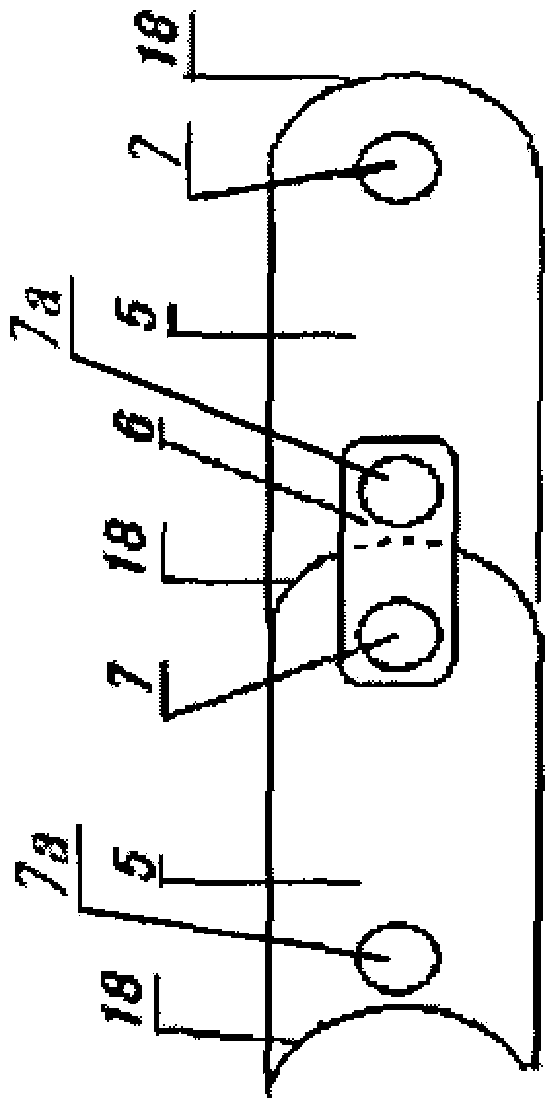

[0025] figure 1 It is a structural schematic diagram of the first embodiment of the metallurgical casting machine. Adjacent casting molds 5 are connected to each other through link plates 6 to form an annular rotary casting mold chain. The casting mold 5 and the link plate 6 are hinged at the chain shaft 7 and fixed at the fixed shaft 7 a, and the casting mold 5 can rotate around the chain shaft 7 . A rotary casting mold chain formed by interlinking a plurality of casting molds 5 and two sprockets 3 located on the upstream and downstream sides are supported by the chain rail frame 15 . The sprocket 3 is driven by an unillustrated motor, thereby pushing the casting mold 5 to rotate, and circulates along a plurality of chain rail rollers 2 fixed on the chain rail frame 15 . A plurality of chain rail rollers 2 play the role of supporting and limiting the turning path of the casting mold 5, and can be arranged separately according to actual needs, as long as the turning path of ...

Embodiment 2

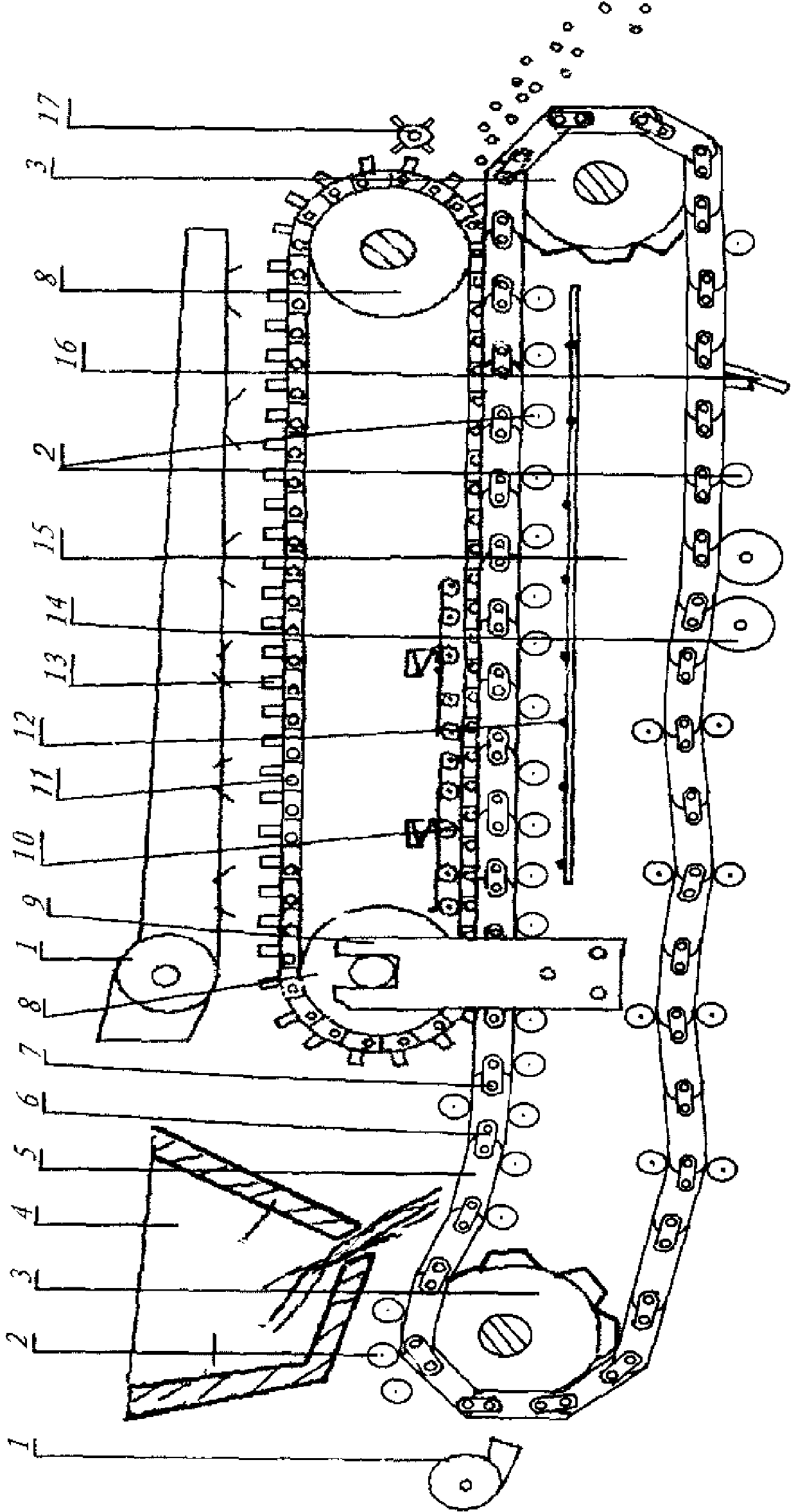

[0028] figure 2It is a structural schematic diagram of the second embodiment of the metallurgical casting machine. The metallurgical casting machine of the second embodiment is also provided with a support wheel 8 and a support wheel frame 9 on the basis of the first embodiment. The support wheel frame 9 supporting the support wheel 8 located on the upstream side is vertically fixed on the chain rail frame 15 . On the two support wheels 8 at the upstream and downstream sides, an endless chain of rotary sizing dies formed by interlinking the sizing dies 13 is encircled. Two support wheels 8 can rotate, and drive the rotary movement of the chain of the rotary shaping die. Adjacent sizing dies 13 are linked to each other at a link axis 11 . The calibrating mold 13 is a convex mould, which has a convex part. During the rotation process, the calibrating mold 13 cooperates with the casting mold 5 in its convexity, synchronously operates to carry out combined molding, and produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com