A fully enclosed mobile silicon carbide smelting furnace

A silicon carbide and smelting furnace technology, which is applied in the field of fully enclosed mobile silicon carbide smelting furnaces, can solve the problems of unusable industrial production, poor operability, and poor safety performance of silicon carbide products, so as to protect the environment and reduce construction costs. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

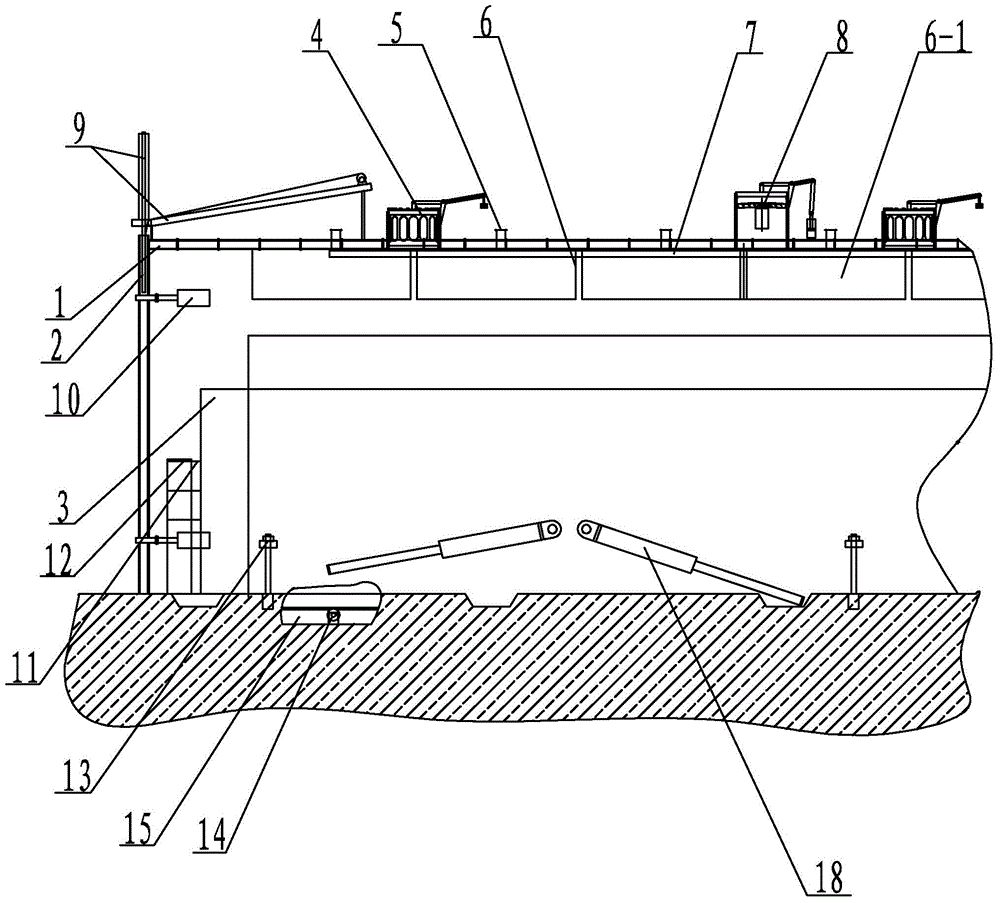

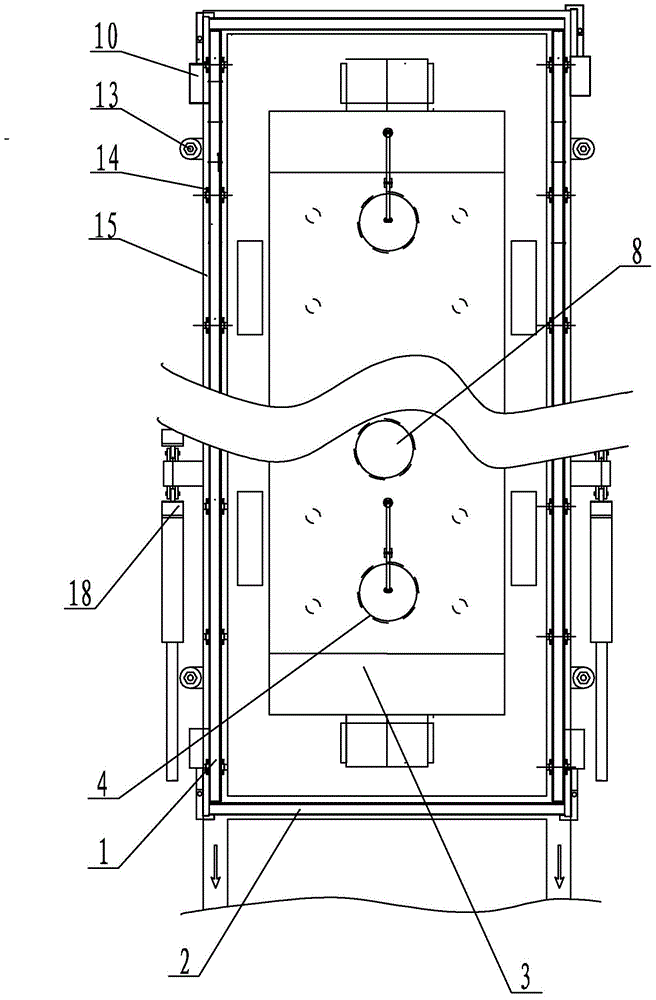

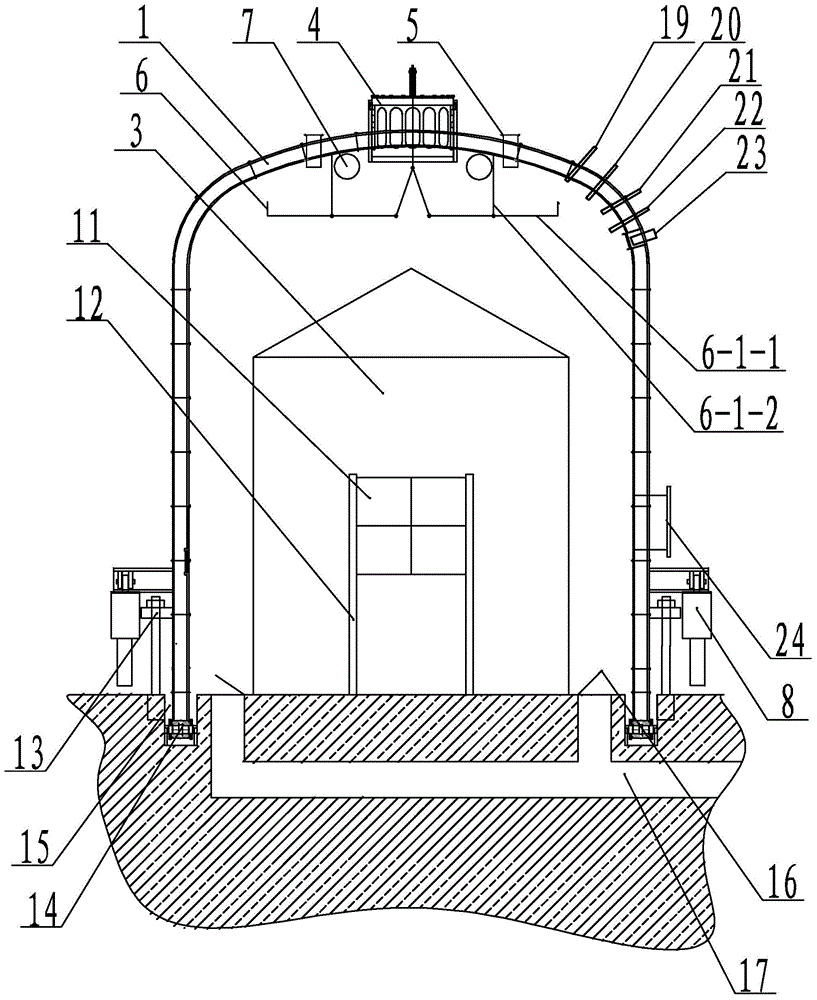

[0017] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 Describe this embodiment, a fully enclosed mobile silicon carbide smelting furnace kiln in this embodiment includes a movable main kiln body 1, a kiln door 2, a silicon carbide smelting furnace 3, multiple automatic pressure relief devices 4, secondary feeding Device 6, nitrogen pipeline 7, electric quick ventilation device 8, door opening device 9, door tightening device 10, electrode 11, power distribution device 12, kiln body locking device 13, ground wheel or walking wheel 14, sealed water tank 15, cover Plate 16, gas collecting pipe 17, mobile device 18, pressure sensor 19, temperature sensor 20, oxygen content sensor 21, CO sensor 22 and remote instrument and camera 23,

[0018] Both ends of the upper part of the movable main kiln body 1 are provided with kiln doors 2 w...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination figure 1 and Figure 10Describe this embodiment, the electric quick ventilation device 8 of this embodiment comprises kettle body 8-1, ventilation fan 8-2, ventilation sealing ring protection device 8-3, ventilation sealing ring 8-4, ventilation upper Cover 8-5, connecting rod mechanism 8-6 and pneumatic actuator 8-7, the inner side wall upper part of pot body 8-1 is provided with and is provided with ventilation sealing ring 8-4 and ventilation sealing ring protection successively from top to bottom Device 8-3, ventilation blower 8-2 is arranged in kettle body 8-1, and ventilation upper cover 8-5 is installed on the kettle body 8-1, and pneumatic actuator 8-7 is arranged on the ventilation upper cover The link mechanism 8-6 on the 8-5 is connected with the kettle body 8-1. Such setting facilitates the replacement of gas in the kiln. Other compositions and connections are the same as in the first embodiment.

[0033] The...

specific Embodiment approach 3

[0034] Specific implementation mode three: combination figure 1 and Figure 7 Describe this embodiment, the door opening device 9 of this embodiment includes two first slide bars 9-1, two first guide grooves 9-2, two second slide bars 9-3, two second guide grooves 9 -4, screw rod 9-5, lifting assembly 9-6, lifting guide assembly 9-7, bracket 9-9, door opening assembly 9-10 and multiple supporting wheels 9-8,

[0035] The support 9-9 is arranged inclined upwards, and the included angle between the support 9-9 and the horizontal plane is 15°, multiple supporting wheels 9-8 are arranged side by side on the support 9-9, and the lifting guide assembly 9-7 is arranged on the support 9 The other end of -9, the kiln door 2 is vertically worn in the lifting guide assembly 9-7, the lifting assembly 9-6 is arranged on the upper end of the lifting guide assembly 9-7, and the output end of the lifting assembly 9-6 is connected to the screw rod 9-7. One end of 5 is connected, the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com