Method for treating low-temperature low-turbidity water through ultrasonic enhanced coagulation

A low-temperature and low-turbidity water and ultrasonic technology, which is used in flocculation/sedimentation water/sewage treatment, mechanical oscillation water/sewage treatment, etc., can solve the problems of poor purification effect and large dosage of coagulant, and reduce dosage The effect of increasing the coagulation efficiency and improving the dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

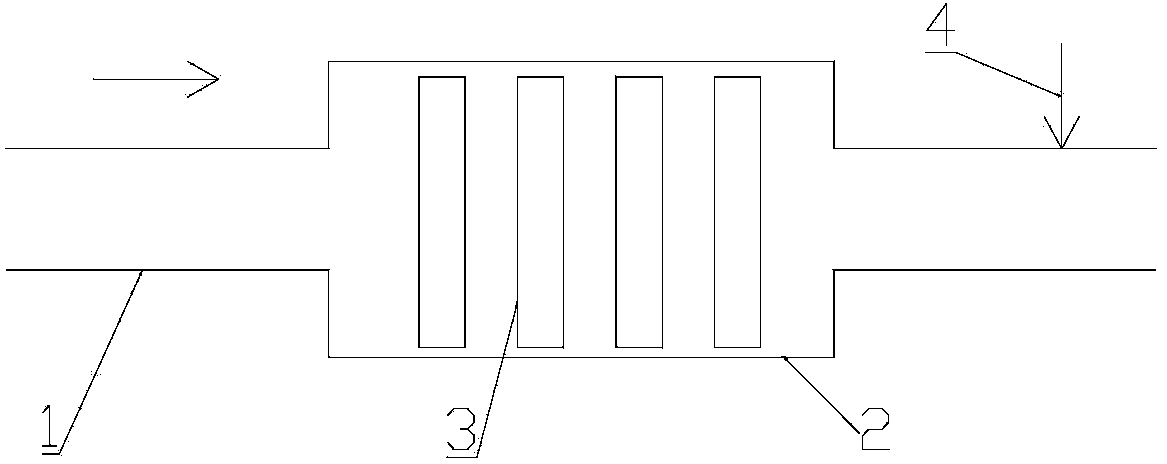

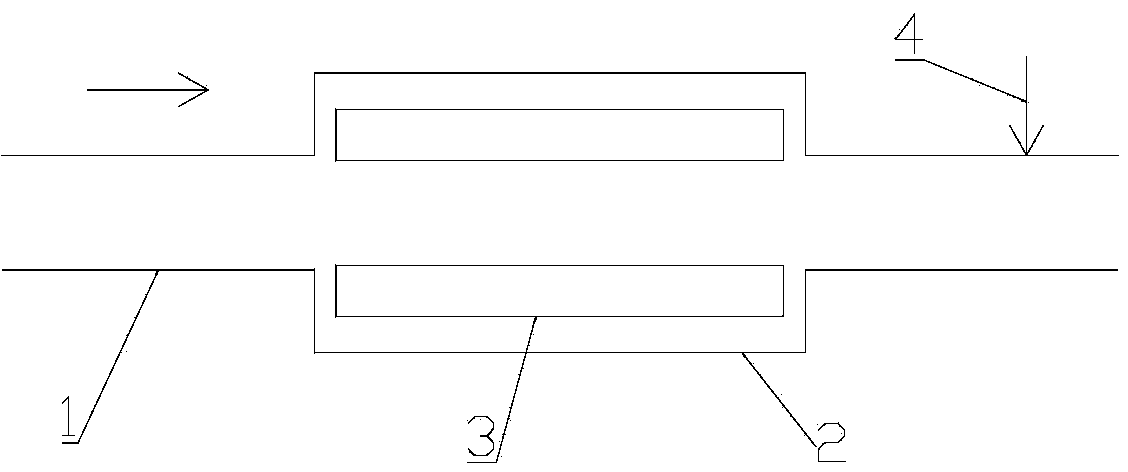

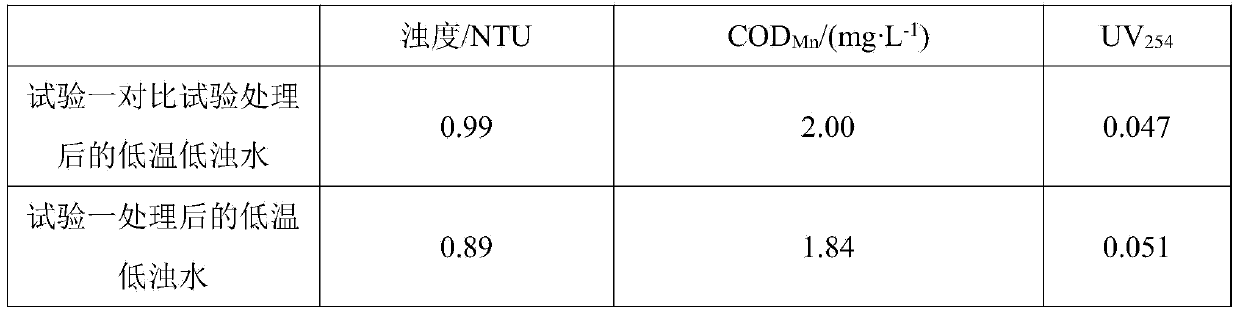

[0012] Specific implementation mode 1: This implementation mode is a method for ultrasonically enhanced coagulation treatment of low-temperature and low-turbidity water, which is specifically completed according to the following steps:

[0013] 1. Water treatment process: Install the ultrasonic processor on the raw water pipeline of low-temperature and low-turbidity water, and set a coagulant dosing port on the raw water pipeline 10m to 60m away from the end of the ultrasonic processor; 2. Water treatment method: low temperature and low The turbid raw water flows through the ultrasonic processor at a certain flow rate, the ultrasonic frequency is 23.5kHz-25kHz and the ultrasonic intensity is 0.50W / cm 2 ~1.50W / cm 2 , the retention time of raw water in the ultrasonic processor is 1s~100s, when the low temperature and low turbidity water after ultrasonic treatment flows through the coagulant dosing port, the dosage is 30mg / L~40mg / L to add coagulant , through the pipeline or coag...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the multi-branch transducers of the ultrasonic processor described in step 1 are fixed on the wall of the ultrasonic processor in parallel with the water inlet pipe, or the ultrasonic processor The multiple transducers of the device are fixed on the wall of the ultrasonic processor perpendicular to the direction of the water inlet pipe. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, a coagulant feeding port is set at a distance of 20 m to 30 m from the end of the ultrasonic processor. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com