Gas-water dual-use filling material plug flow device

A dual-purpose, power device technology, applied in the field of water treatment, can solve the problems of affecting the water quality and quantity of water supply and drainage purification treatment, the filler is easily exposed to the sun, affecting the water quality of purification treatment, etc., so as to improve the efficiency of biological oxidation treatment and increase biological hanging The effect of film volume and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely below with reference to the accompanying drawings in the embodiments of the present invention.

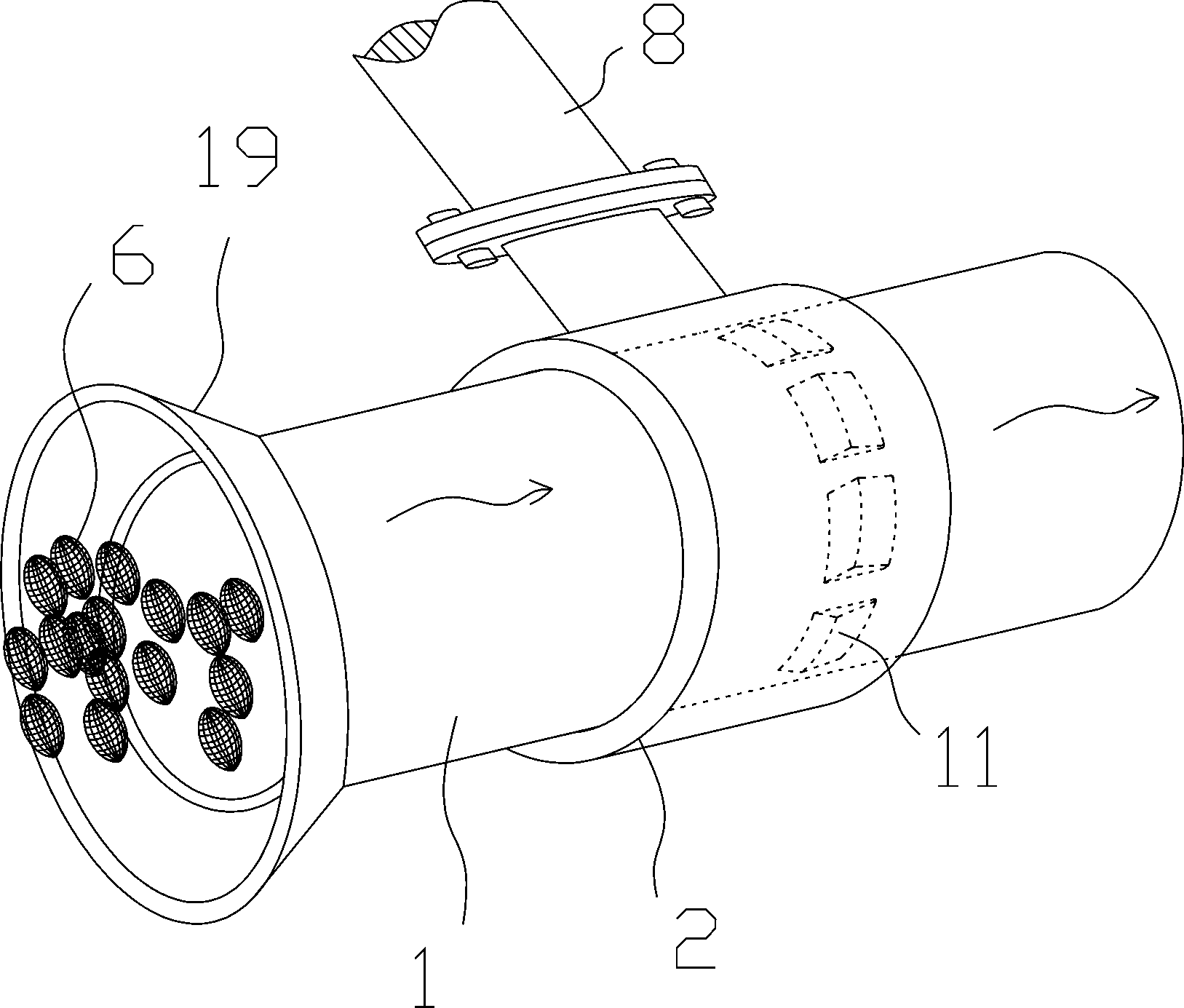

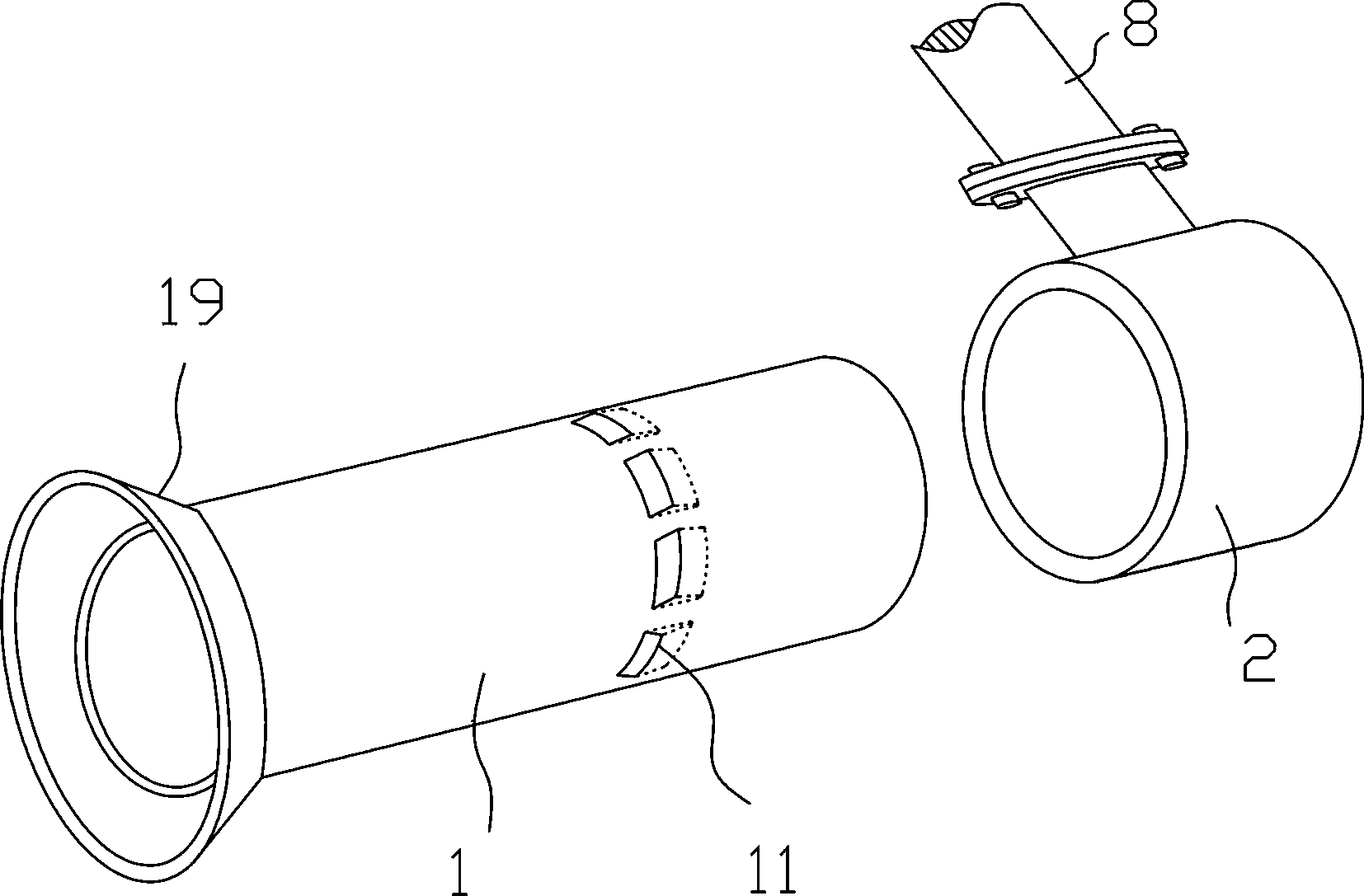

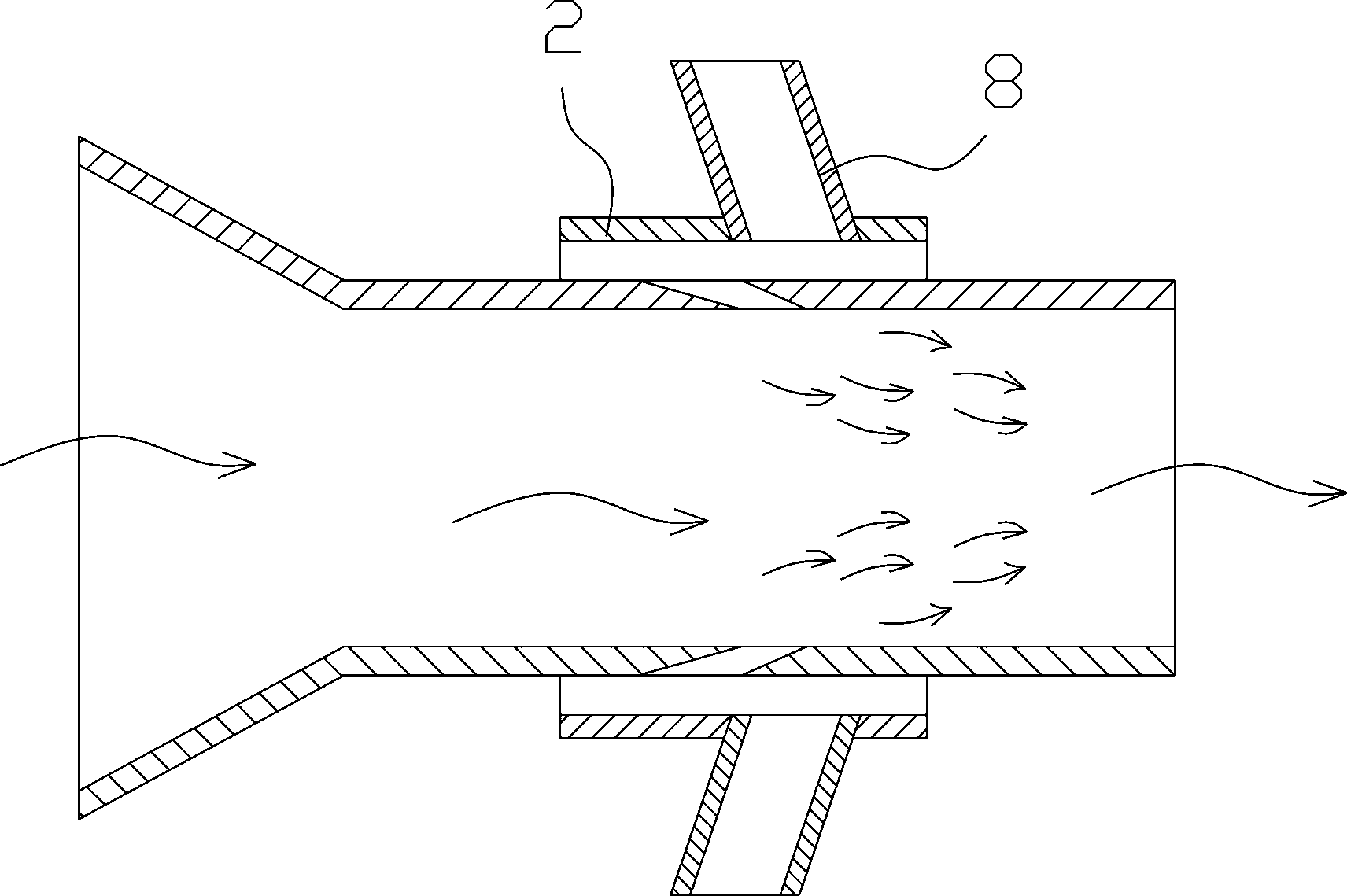

[0025] like Figure 1-3 As shown in the figure, a gas-water dual-purpose type packing circulation push-flow device includes a feeding pipe 1 for conveying the packing 6, a power device, a guide part 2 for conveying a medium, and a spray part. Specifically, the power device is: The air source or water source can be introduced from the treatment plant and does not need to be provided separately. For example, it can be the same air source as the aeration pipe, which is shown in the drawings; the injection part is used to guide the medium in the conveying part and can be used for conveying the material. It moves in the pipe, and generates thrust or suction that can pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com