Intelligent flow-variable spraying controller based on laser detection

A laser detection and controller technology, applied in the direction of flow control using electrical devices, program control in sequence/logic controllers, electrical program control, etc., can solve the problems of pesticide waste, low efficiency, and uneven spray distribution. To achieve the effect of good flow control linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

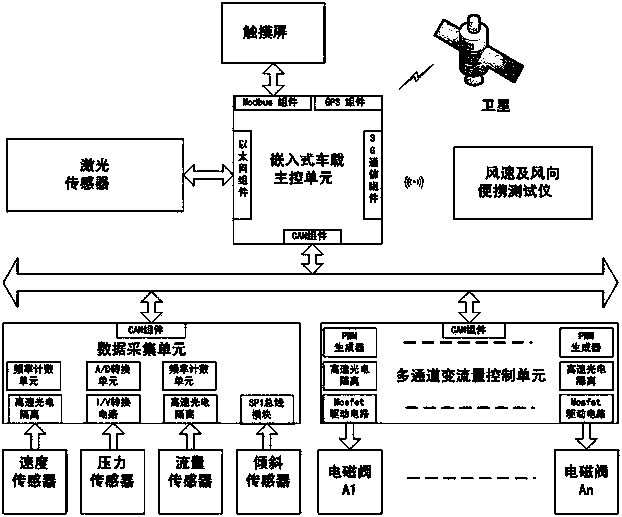

[0019] exist figure 1 Among them, an intelligent variable spray controller using laser detection, consisting of a laser sensor, a touch screen, an embedded vehicle-mounted main control unit, an Ethernet component, a 3G communication component, a Modbus component, a CAN component, a GPS component, and a portable wind speed and wind direction tester , data acquisition unit, frequency counting unit, A / D conversion unit, I / V conversion circuit, frequency counting unit, SPI bus module, speed sensor, pressure sensor, flow sensor, tilt sensor, multi-channel variable flow control unit and multiple groups PWM generator, high-speed photoelectric isolation, MOSFET drive circuit, solenoid valve (A1 ~ An) composed of module groups. The embedded vehicle main control unit integrates Ethernet components, 3G communication components, Modbus components, CAN components, and GP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com