Gaussian process based injection molding forming process robust design and tolerance design method

A Gaussian process and robust design technology, which is applied in computing, special data processing applications, instruments, etc., can solve the problems of high design cycle, high cost, and long calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

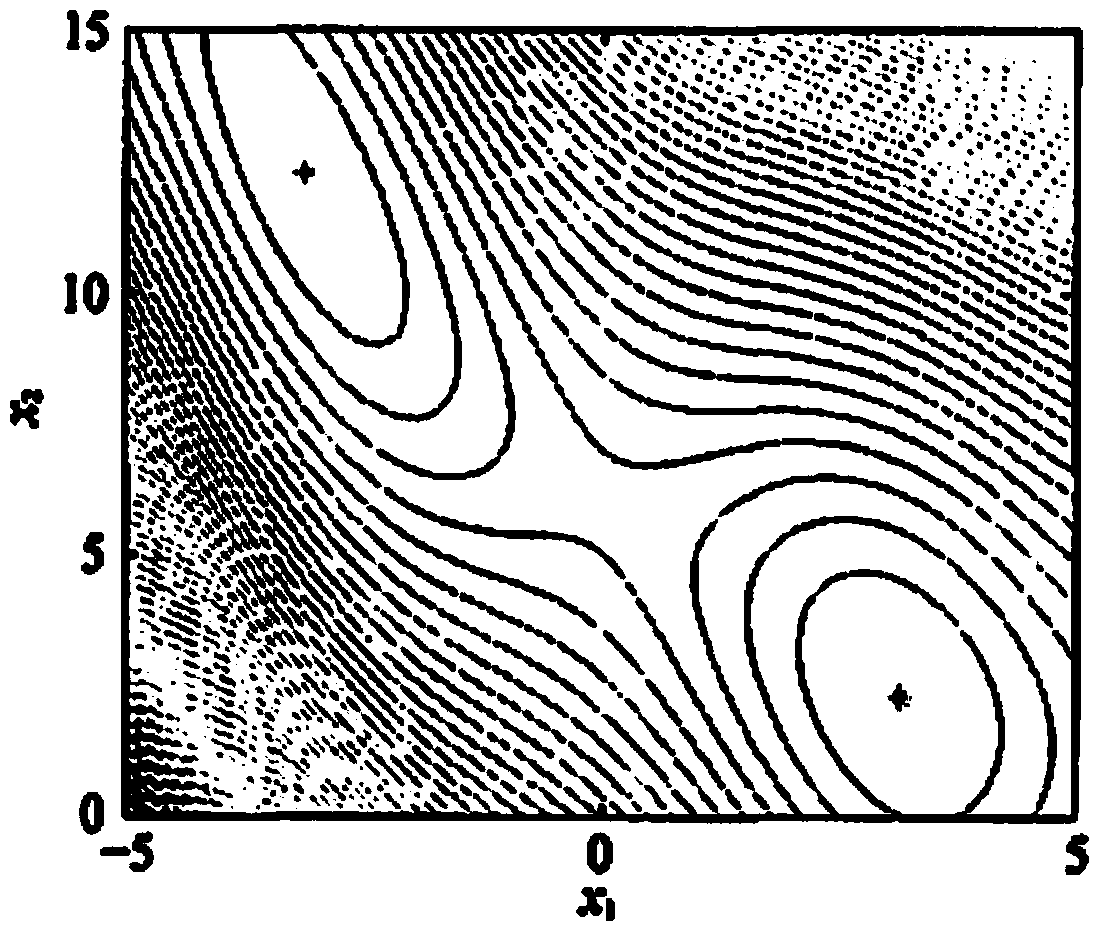

[0056] A Numerical Example for Finding a Robust Solution

[0057] A Gaussian process-based robust design and tolerance design method, including experimental design method sampling, correlation analysis based on Gaussian process, robust design and tolerance design, specifically including the following steps:

[0058] Step 1. Find the problem according to the value given by the user. Its mathematical description is as in formula (12). Take 10 initial training samples through the Latin hypercube sampling method and bring them into the analytical formula of formula (12) to obtain the response value, and Combined with its sample set to form a training data set;

[0059] f ( x ) = ( x 2 ...

Embodiment 2

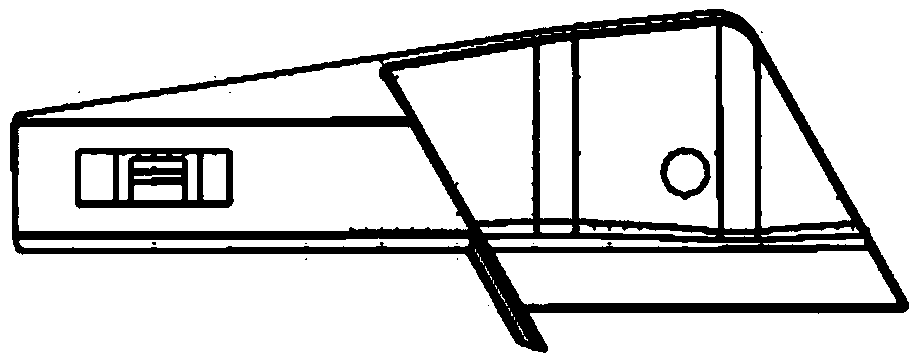

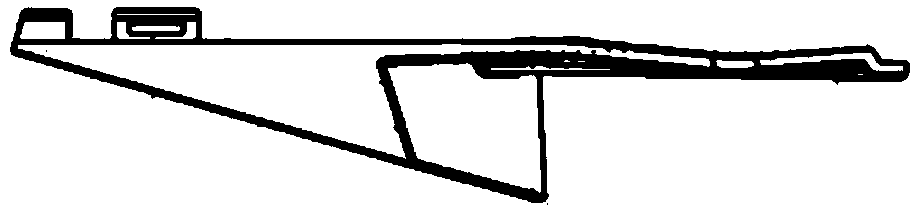

[0068] Application of Robust Design and Tolerance Design Method for Injection Molding Process Control Based on Gaussian Process in Injection Molding

[0069] The robust design and tolerance design method based on Gaussian process is used to optimize an automobile glass run channel. Its two-dimensional modeling diagram and cross-sectional view are as follows Figure 2-Figure 6 As shown, the process of robust design and tolerance design of injection molding process parameters is as follows Figure 7 shown, including the following steps:

[0070] Step 1. According to the process documents formulated by the customer, select the molding process parameters to be optimized and determine their value range: melt temperature T w =190℃~230℃; mold temperature T m =40℃~75℃; injection time t i =2s~4s; Holding time t p =5s~25s; injection pressure P i =60Mpa~190Mpa; holding pressure P p =60Mpa~160Mpa. The experimental design was carried out through the enhanced translational propagatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com