Large vertical electromotor for third-generation nuclear power plant sea water circulating pump

A technology for circulating water pumps and nuclear power plants, which is applied in the direction of asynchronous induction motors, electrical components, electromechanical devices, etc. It can solve the problems of high rigidity requirements for pressure-bearing parts of motors, influence of motor structures, and difficult ventilation of motors, so as to eliminate oil leakage in bearing chambers and oil atomization, stable performance, and improved operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

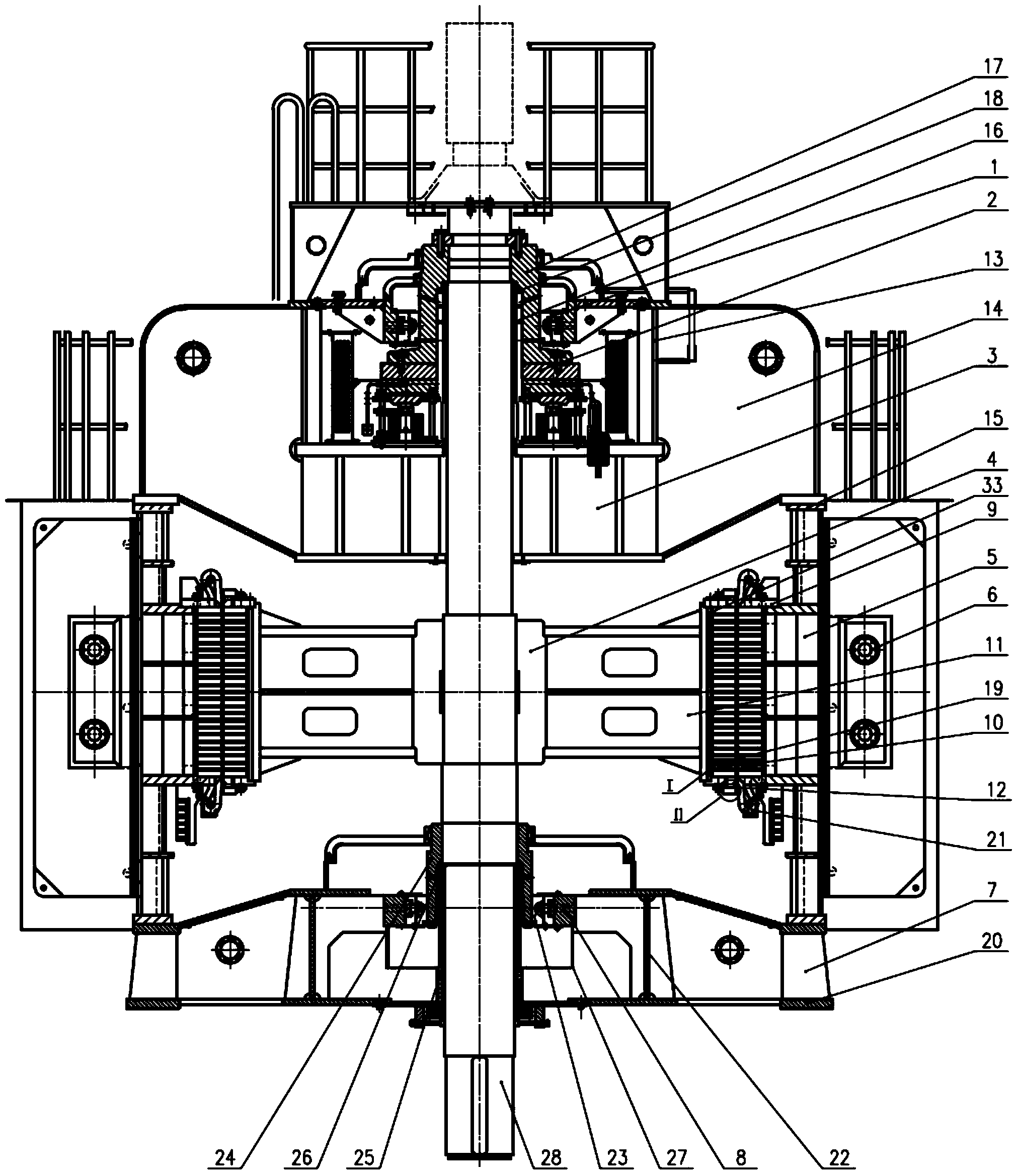

[0020] Such as figure 1 Shown is a large vertical motor for circulating water pumps in third-generation nuclear power plants, which consists of a stator 5, a rotor 4, an upper frame 3, a thrust bearing 2, an upper guide bearing 1, a lower frame 7, a lower guide bearing 8, and a cooler 6 , the upper frame 3, the stator 5 and the lower frame 7 are integrated from top to bottom. The motor model is YLKS7700-36, with a rated power of 7700kW, a rated voltage of 10kV, a rated current of 624A, a rated speed of 164r / min, and a magnetic field synchronous speed of 166.7 r / min rated frequency 50Hz, 3 phases, insulation class F.

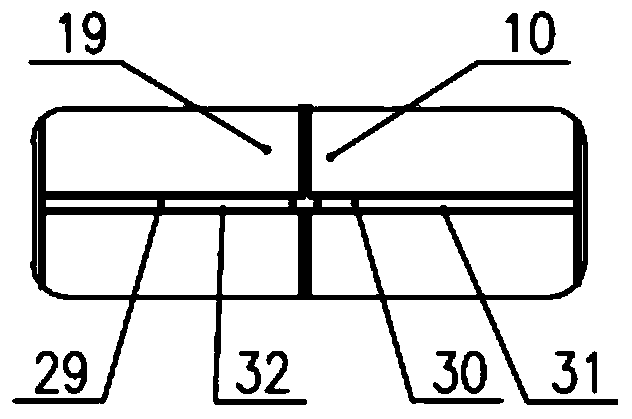

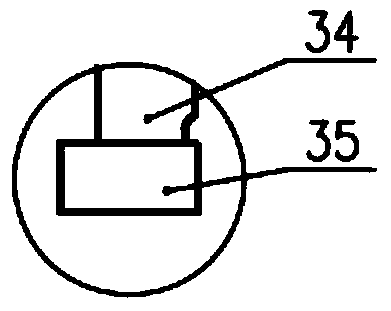

[0021] The stator 5 includes a stator base 15, a stator core 10 and a stator winding 21. The stator base 15 is mainly welded by steel plates, and carries all the weight through round steel, angle steel, vertical ribs, etc. The stator core 10 is made of insulating paint. The stator punches are stacked and fastened between the two end pressure plates 9 of the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com