Operation logic of an organic material thermohydrolysis system

A technology of operation logic and organic matter, which is applied in the field of operation logic of organic matter thermal heating and water splitting system, can solve the problems of ineffective digestion and dehydration cake, ineffective use of waste energy, ineffective utilization, etc., so as to shorten the digestion processing time. , The effect of shortening sludge digestion and treatment time, rapid and effective reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

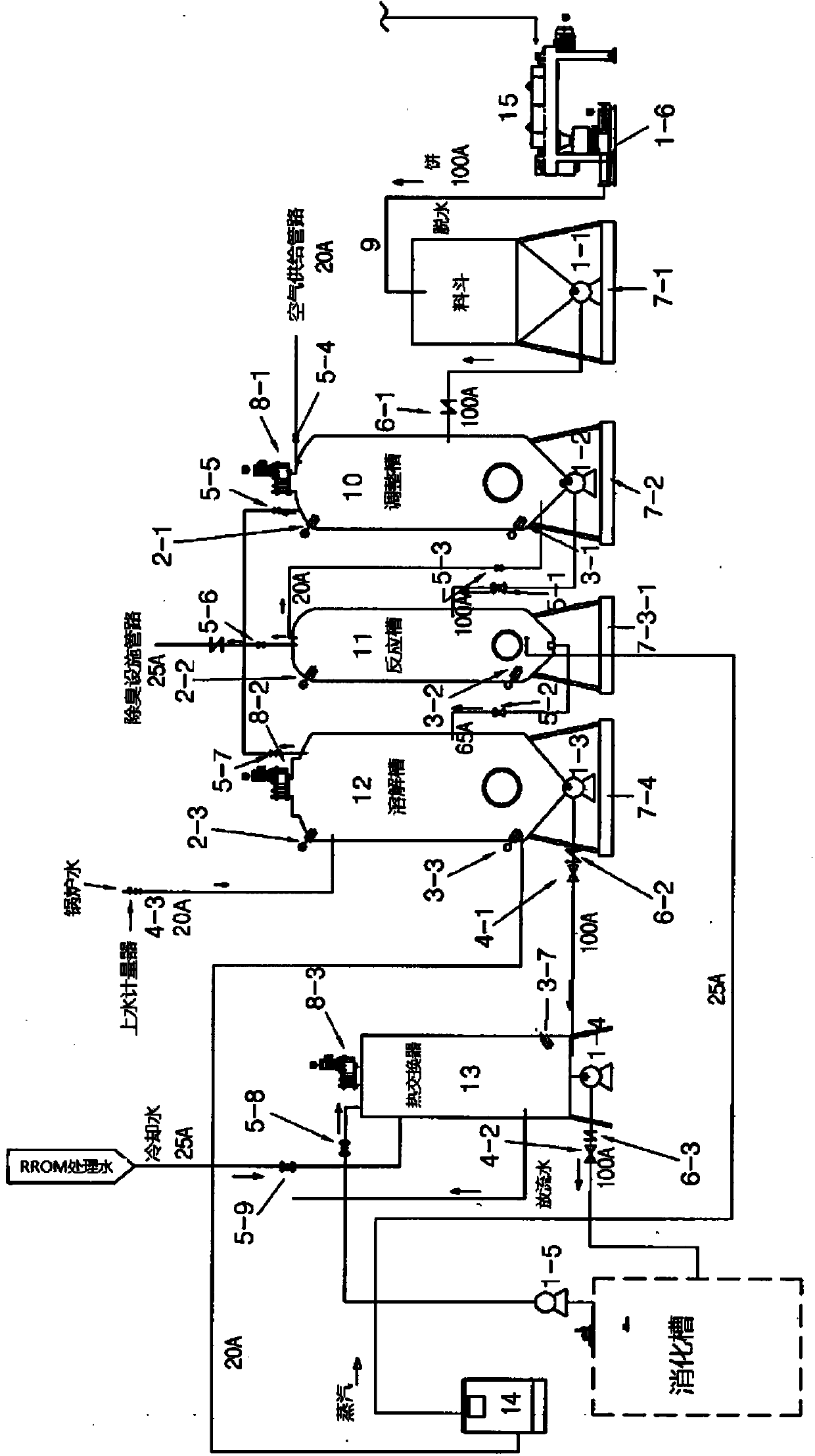

[0039] A specific embodiment of the invention is observed based on the drawings.

[0040] According to an embodiment of the present invention, it is divided into figure 1 with running logic applied in Figure 2 to Figure 4 The operating logic of the organic matter thermal hydrolysis system and for the Figure 5 with running logic applied in Figure 2 to Figure 4 The operation logic of the organic matter thermal hydrolysis system is described.

[0041] Figure 1 to Figure 4 What is shown and described is the operation logic when a reaction tank is set between the adjustment tank and the dissolution tank, and it applies to Figure 5 of operating logic Figure 6 to Figure 12 What is illustrated and described is the operation logic when two or more reaction tanks are installed between the adjustment tank and the dissolution tank.

[0042] The purpose of the present invention is to improve the digestion efficiency of sludge and improve the dehydration property after digestion...

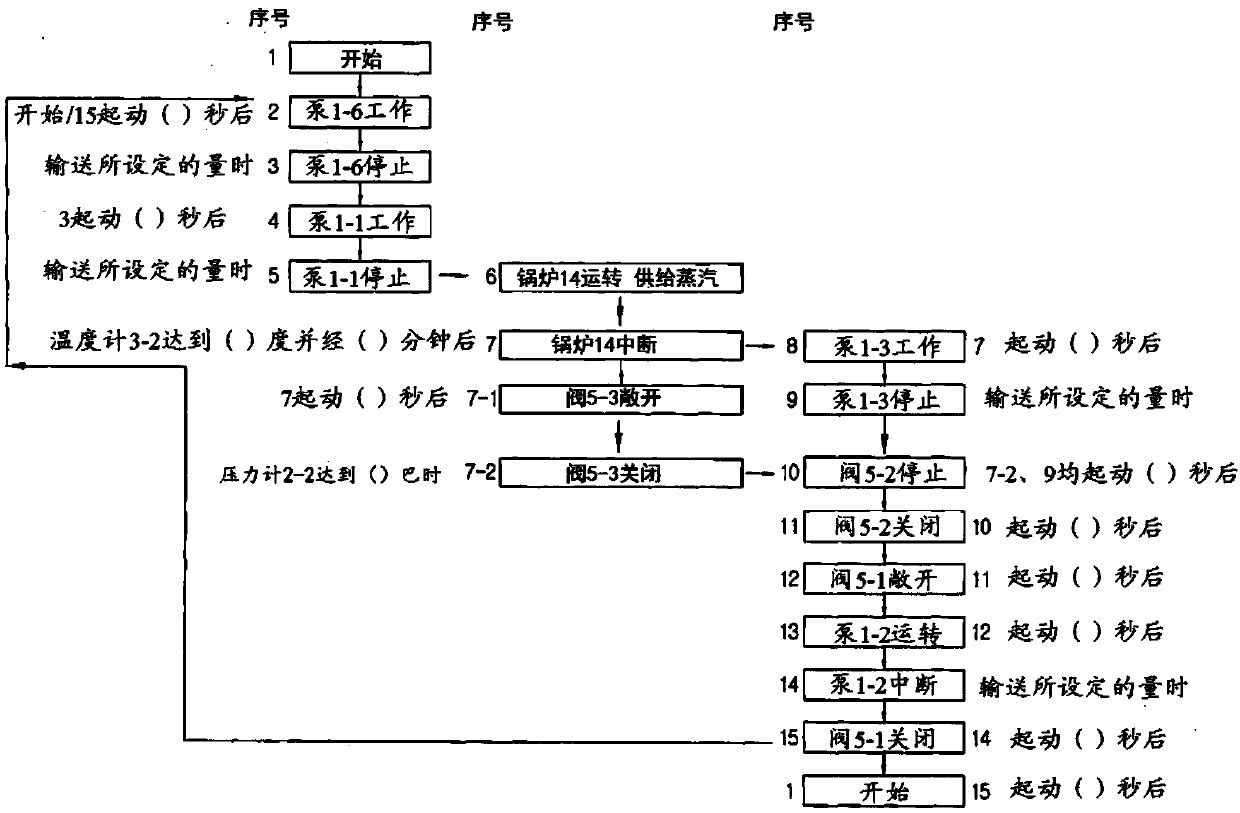

Embodiment 1

[0059] based on figure 2 Observe Example 1 according to the invention.

[0060] exist figure 1 In the thermal hydrolysis system for organic matter, the sludge supply pump 1-6 is equipped to operate, and the hopper load cell 7-1 installed at the lower end of the hopper is used to continuously measure the weight of the injected sludge while feeding the sludge to the hopper through the conveying pipeline. This is a step of transferring sludge equivalent to the set amount and stopping the operation of the sludge supply pump.

[0061] The amount of sludge injected into the hopper is measured by the hopper load cell 7-1 provided at the lower part of the hopper, and the amount of sludge corresponding to the amount set in the PLC is sent to the hopper. As for the amount of sludge injected and stored in the hopper, it is desirable that the set amount is 5 times to 10 times the amount of sludge treated at one time by the reaction tank which is the core configuration of the present in...

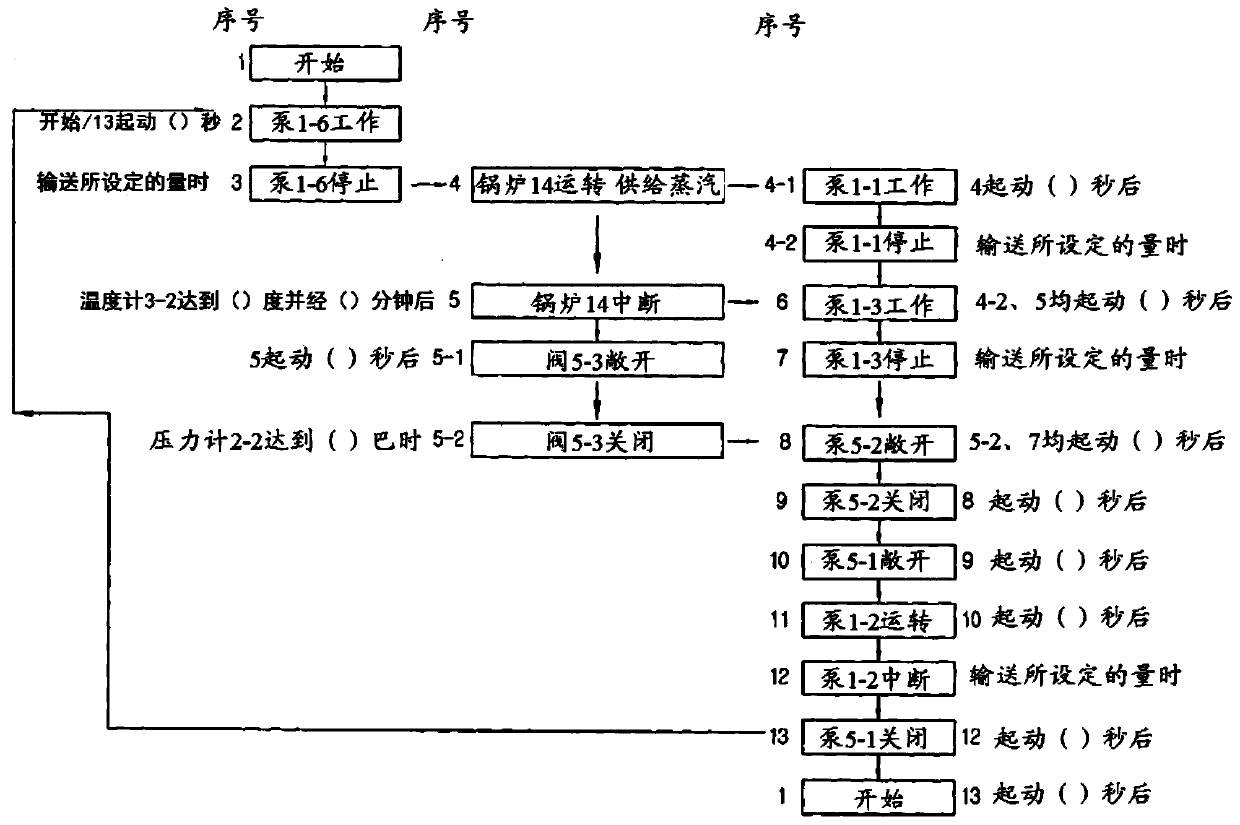

Embodiment 2

[0076] based on image 3 The operation logic is observed according to Embodiment 2 of the present invention.

[0077] exist figure 1 The thermal hydrolysis system for organic matter includes operating the sludge supply pump 1-6, and using the hopper load cell 7-1 arranged at the lower end of the hopper to continuously measure the weight of the injected sludge while transporting it to the hopper with the set one. A step in which a certain amount of sludge is equivalent and the operation of the sludge supply pump is stopped.

[0078] The load cell installed at the lower part of the hopper is linked with the sludge supply pump to continuously measure the amount of sludge injected into the hopper with the load cell, and inject the sludge equivalent to the amount set in the PLC or microcomputer. In terms of the amount of sludge injected and stored in the hopper, it is desirable to set the amount between 5 and 10 times the amount of sludge that is processed at one time in the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com