How to make straight white tea

A production method and straight strip technology, applied in the field of tea science, can solve the problems that affect the flavor and health function of traditional white tea, propose new white tea without white tea, and the shape is not tight enough, so as to facilitate subsequent shaping and improve the quality of appearance , loose shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of straight white tea, its steps are as follows:

[0026] 1) Raw materials of fresh leaves: single buds or one bud and one leaf of tea tree are used as raw materials.

[0027] 2) Withering process: put the clean bamboo mat in a clean, ventilated, and dry place indoors, and spread the picked fresh leaves on the bamboo mat made of bamboo strips lightly. The thickness of the spread leaves should not exceed 1cm. Be careful not to injure the buds and leaves, and wither until the water content of the tea leaves is at 45% (mass percentage).

[0028] 3) Steaming: After the tea leaves that have passed the withering process are steamed for 1 minute, they are quickly dispersed to dissipate heat and dry the moisture on the surface of the dried leaves.

[0029] 4) Shaping process: After the moisture on the surface of the green leaves is dried, use a rafting machine or a multifunctional machine to make the shape. Make the shape for 10 minutes, add stick...

Embodiment 2

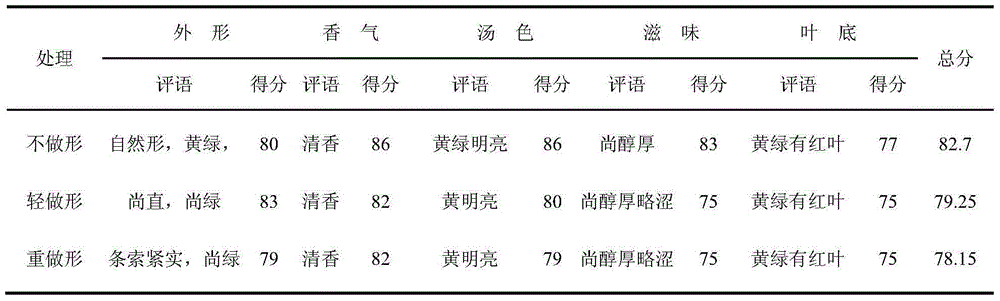

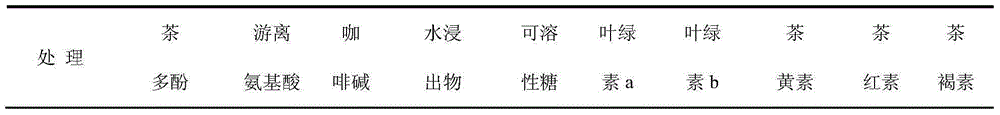

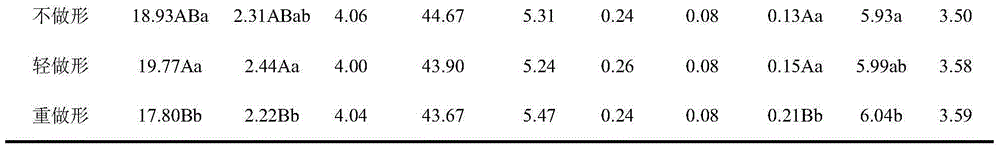

[0034] Sensory evaluation, physical and chemical analysis and color analysis of white tea shape

[0035] In this embodiment, except for the shaping in step 4), it is treated as no shaping, light shaping and heavy shaping respectively. The raw material is Fuding Dabai tea tree bud two and three Leaves, picked in July, 2013, other steps are identical with embodiment 1,

[0036] The treatment method of light shaping: shape for 10 minutes, and add rods for 1 minute during this period.

[0037] The treatment method for reshaping: knead for 20 minutes, shape for 10 minutes, and add rods for 1 minute during this period.

[0038] The shape-making is as follows: after 3 minutes of shaping in the rafting machine, start adding rods, the weight of which is 480g, and quickly take out the rods after adding rods for 1 minute, continue shaping for 6 minutes, and then take out of the pot.

[0039] The finished tea leaves prepared are detected according to the conventional methods in this fie...

Embodiment 3

[0053] Optimization of parameters such as water content of withered leaves, steam killing time and drying temperature

[0054] Use L 9 (3 4 ) orthogonal table to carry out the orthogonal test, the test factors and levels are as shown in Table 4, the raw material is a single bud of the Huazhong Agricultural University tea base Fuding Dabai tree, which was picked in August 2013, and the preparation steps of the white tea are the same as in Example 1. See Table 5 for sensory evaluation results, Table 6 for physical and chemical analysis results, and Table 7 for color analysis results.

[0055] It can be seen from Table 5 that when the water content of withered leaves was 60%, each tea sample failed to show the quality characteristics of white tea, and the total score of sensory evaluation was lower than that of 30% and 45% white tea samples; The total score of 45% white tea is higher, but the shape score is lower than that of 45% white tea, which shows that 30% withered water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com