Wet electric precipitator

A wet electrostatic precipitator, anode plate technology, applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of increasing flue gas flow rate, unfavorable dust removal, increasing the load of absorption tower, etc., to achieve effective collection. The effect of increasing the dust area, increasing the effective dust collecting area and ensuring the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to explain the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to these drawings without creative efforts.

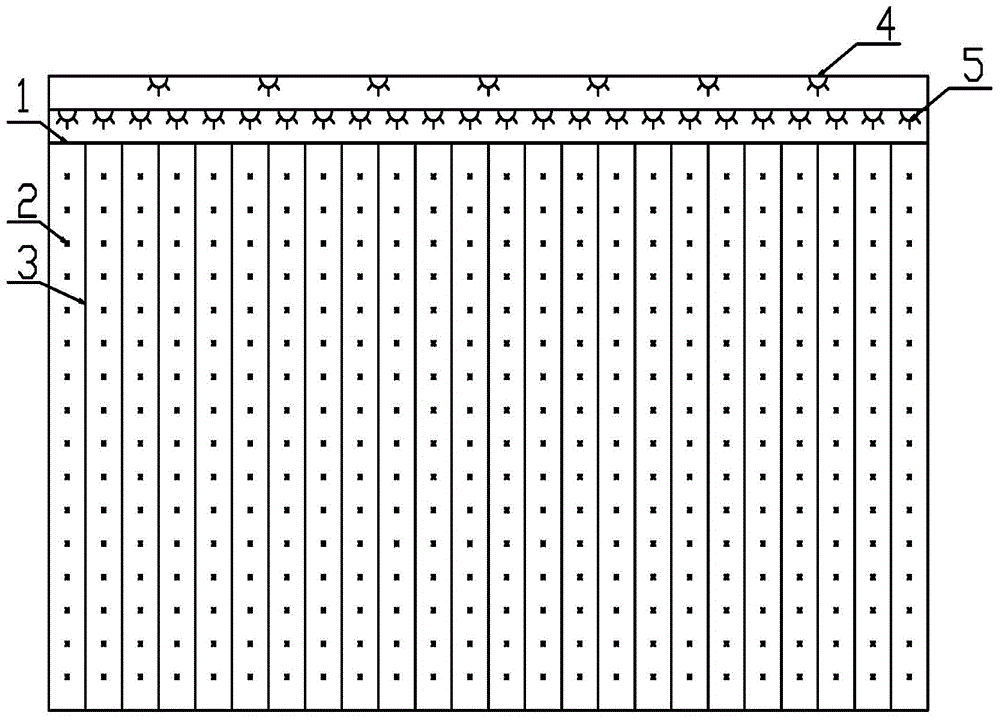

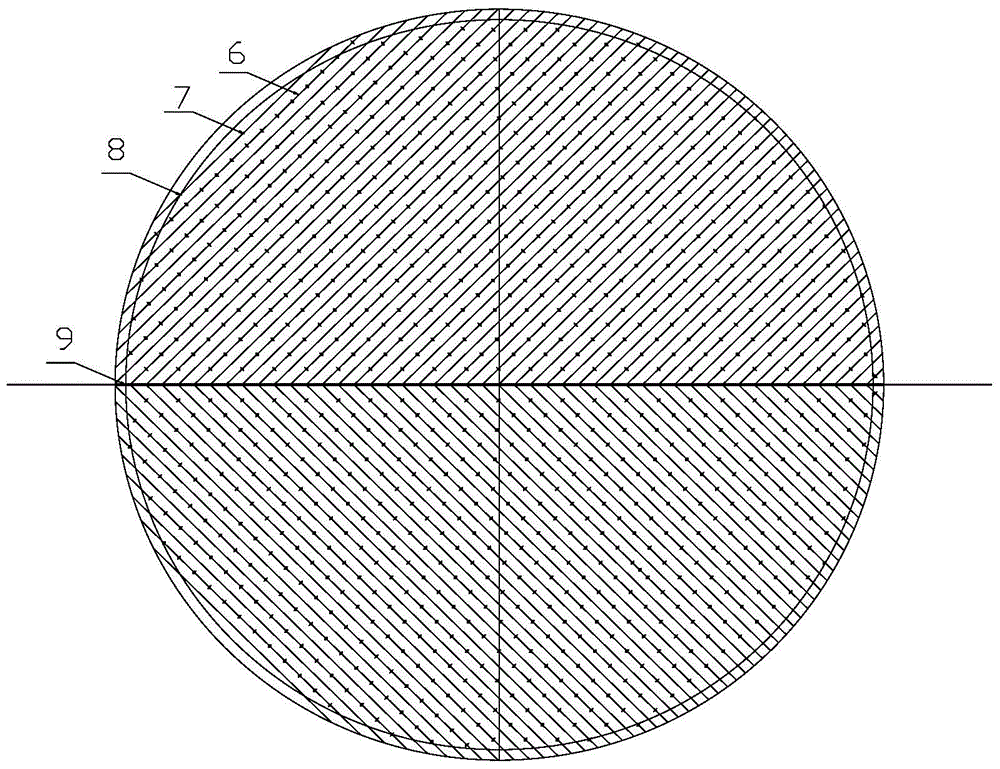

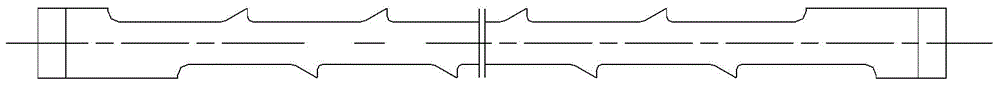

[0046] In one embodiment of the present invention, refer to figure 1 , figure 2A wet electrostatic precipitator includes: a cylindrical shell, an anode plate 3, a cathode line 2, an anode plate washing nozzle 5, and a cathode line washing nozzle 4; the anode plate includes two groups of symmetrically distributed anode plates, and the symmetry plane is An axial surface ( figure 2 For a top view, the plane of symmetry can be understood as a plane represented by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com