Method for preparing monolithic shell shape by gasification combustion of mold shell roasting pattern

A shape and roasting technology, which is applied in the field of shell casting, can solve the problems of subcutaneous air holes and irritating odor castings, and achieve the effect of avoiding carbon increase, solving irritating odor, and reducing dewaxing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

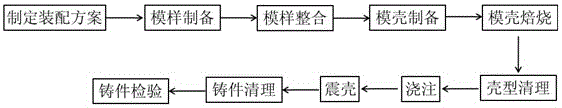

[0018] like figure 1 As shown, the method of preparing the overall shell shape by gasification and combustion of the high-temperature roasting pattern of the mold shell is used to trial-produce the nickel-based alloy impeller, including the following steps:

[0019] Step 1: Use polyethylene (PE) plastic as the pattern material, design and manufacture pattern forming molds, and use injection molding to make patterns such as sprue cups, runners and castings.

[0020] Step 2. According to the design requirements of the casting process, the three impeller shapes are arranged at 120° on the same horizontal plane, and the sprue cup, sprue, and castings are bonded and assembled into an overall shape and trimmed according to technical requirements.

[0021] Step 3, dip-coat the surface layer slurry, shake the slurry, sprinkle surface sand, and dry for 20 to 28 hours to make the surface layer; after the surface layer is dried, dip-coat the back layer slurry and sprinkle sand , Dry for...

Embodiment 2

[0026] In this embodiment, the traditional investment casting method is used to produce the nickel-based alloy impeller, including the following steps:

[0027] Step 1. Design and manufacture the mold, use B576 / medium temperature wax to make wax molds such as sprue cups, runners and castings.

[0028] Step 2. According to the design requirements of the casting process, the three impeller wax molds are arranged at 120° on the same horizontal plane, and the sprue cup, sprue and castings are bonded and assembled to form an overall wax mold group and carried out according to the technical requirements. Trimming.

[0029] Step 3, dip-coat the surface layer slurry, shake the slurry, sprinkle surface sand, and dry for 20 to 28 hours in sequence to make the surface layer; after the surface layer is dried, dip-coat the back layer slurry and sprinkle sand , Dry for 6-8 hours, and repeat 2 times to make the first back layer and the second back layer; use the back layer slurry as the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com