Waste tyre rubber powder preparation device with dust removing device

A technology of waste tire rubber and dust removal device, applied in the direction of removing smoke and dust, sieves, grilles, etc., can solve the problems of heavy dust, poor working environment, unfavorable physical and mental health of workers, etc., to reduce dust emissions and improve the workshop environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

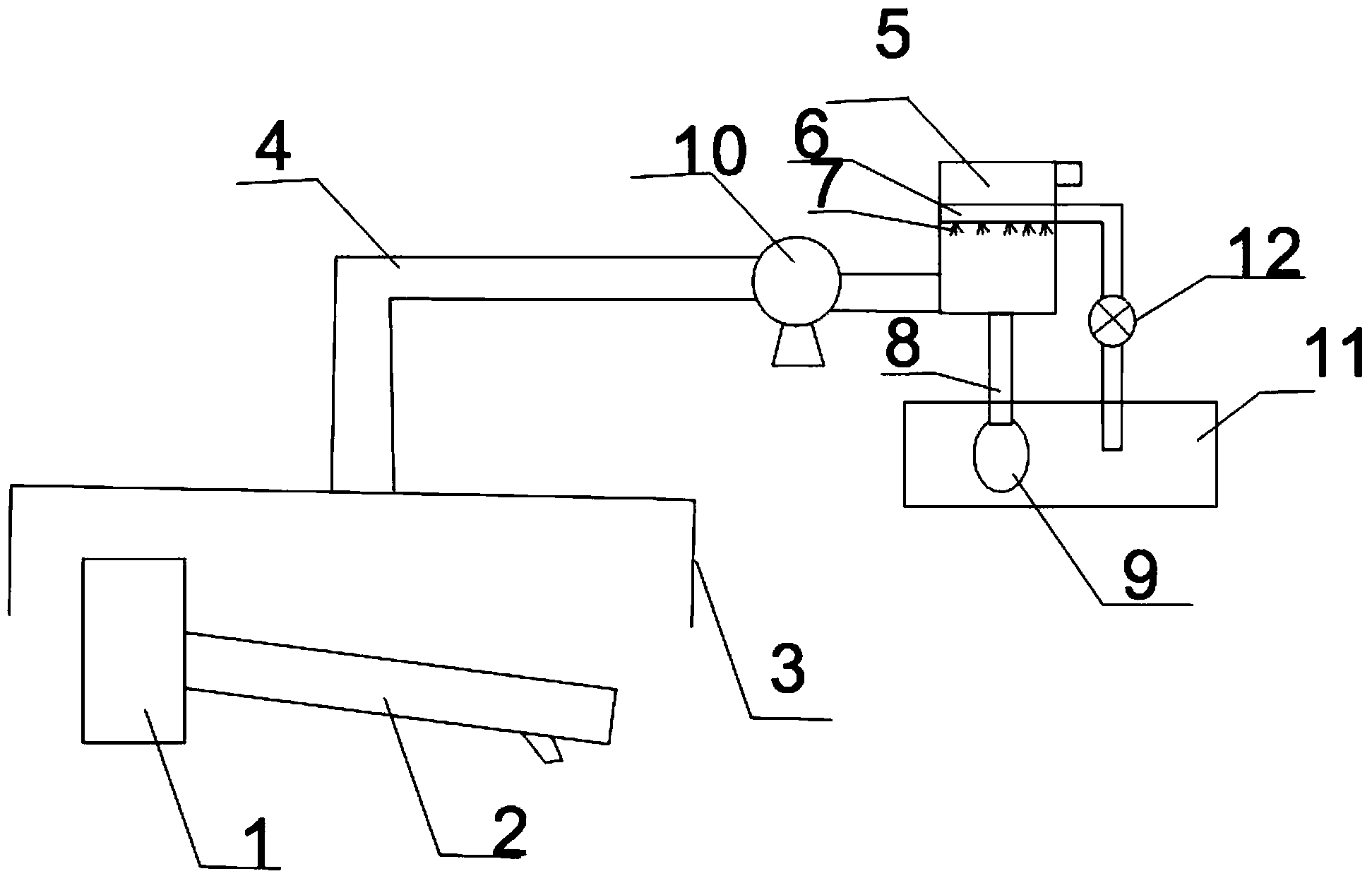

[0013] like figure 1 As shown, the waste tire rubber powder preparation device with a dust removal device of the present invention has a right rubber pulverizer 1, a vibrating screen 2, a dust cover 3, an air duct 4, a dust removal box 5, a spray water pipe 6, a nozzle 7, and a drainage Tube 8, cloth bag 9, induced draft fan 10, pool 11, water pump 12 and other components.

[0014] The head of the vibrating screen 2 is located below the discharge port of the rubber pulverizer 1. The vibrating screen 2 includes a sieve box, and a screen is arranged in the sieve box to divide the sieve box into an upper coarse particle chamber and a lower fine rubber powder chamber. The tail of the fine rubber sub-chamber is provided with a hopper, and the tail of the upper coarse particle chamber is also provided with a discharge port. The discharge port is located above the conveyor belt, and the conveyor belt transports the coarse particles back to the pulverizer 1. This is the prior art. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com