Motor car of 100% low-floor tramcar and assembly method of motor car

A tram and low-floor technology, applied in the direction of railway car body, transportation and packaging, railway car body parts, etc., can solve the problem of lower plasticity and impact toughness of car body, lower mechanical performance and physical performance, and reduce the use of motor car body Years and other issues, to achieve the effect of reducing the total weight of the car body, reducing the weight of the car body, and good production independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] All the features disclosed in this specification, or all disclosed methods or steps in the process, except for mutually exclusive features and / or steps, can be combined in any manner.

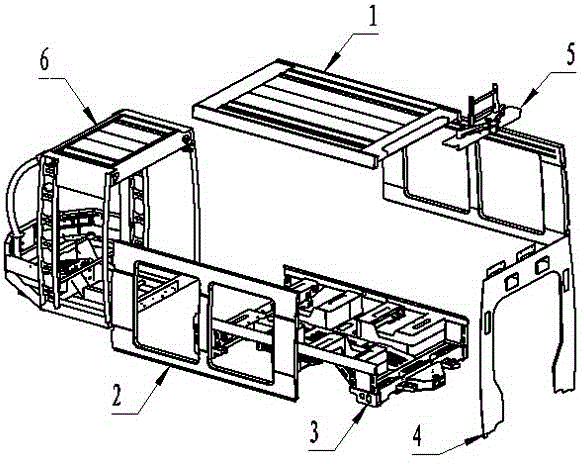

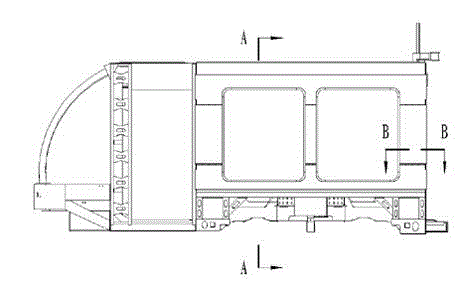

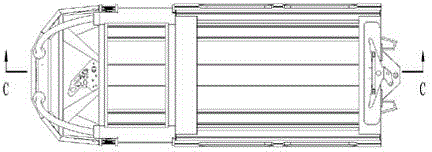

[0032] Such as figure 1 , figure 2 , image 3 As shown, a 100% low-floor tramcar includes a top frame 1, a side wall 2, a bottom frame 3, an end wall 4, an upper hinge assembly 5, and a driver's cab 6. The top frame 1 and the side wall 2 Riveting, the side wall 2 is riveted to the bottom frame 3, the end wall 4 is riveted to the side wall 2, the bottom frame 3, the cab 6 is riveted to the top frame 1 and the bottom frame 3, and the upper hinge assembly 5 is riveted to The roof frame 1 and the end wall 4 are riveted, and the rear end of the motor car body is connected to the floating car through the upper hinge mounting seat 5.

[0033] Such as Figure 4 , Figure 7 As shown, the positions on both sides of the top frame 1 are made into a step shape, the upper position of the side wall 2 is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com