Method for preparing fluoromethane

A monofluoromethane and catalyst technology, applied in the field of preparation of monofluoromethane, can solve the problems of difficulty in industrialization, high production cost, unsatisfactory catalyst life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

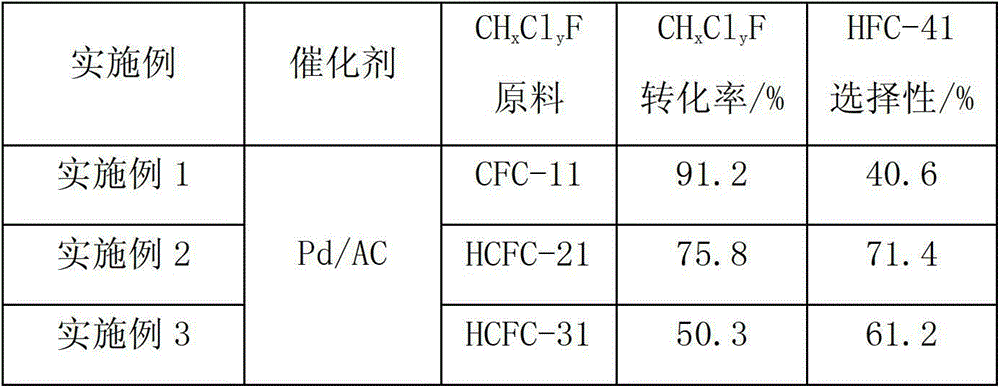

Embodiment 1

[0021] Add 1g of Pd / AC (Pd mass content 2%) catalyst into the gas-phase catalytic hydrodechlorination reaction device, H 2 In the atmosphere, the temperature was raised from room temperature to 350°C over 2h, and the online reduction was carried out at 350°C for 2h. Then lower the temperature to 250°C, switch to reaction gas, at the volume ratio H 2 :CFC-11=4:1 (total flow rate 10ml / min), normal pressure reaction.

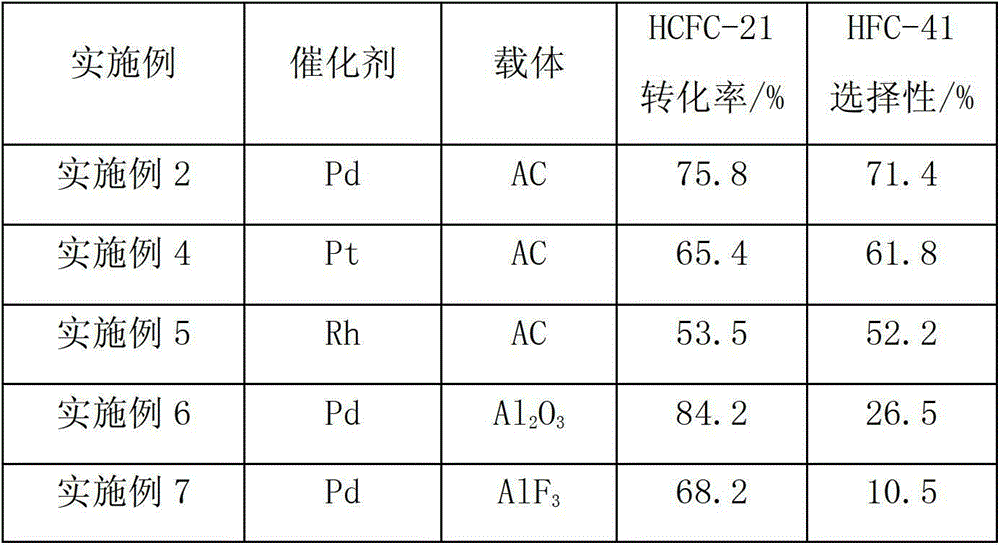

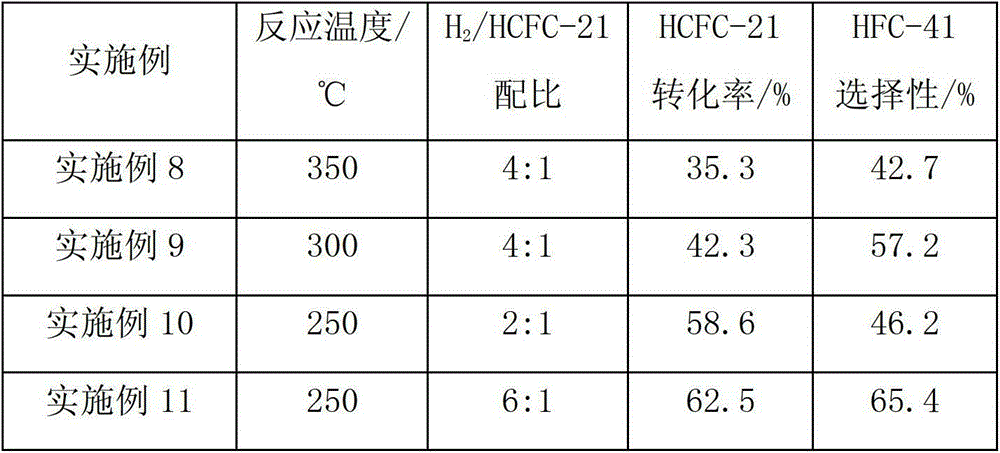

Embodiment 2

[0023] Add 1g of Pd / AC (Pd mass content 2%) catalyst into the gas-phase catalytic hydrodechlorination reaction device, H 2 In the atmosphere, the temperature was raised from room temperature to 350°C over 2h, and the online reduction was carried out at 350°C for 2h. Then lower the temperature to 250°C, switch to reaction gas, at the volume ratio H 2 :HCFC-21=4:1 (total flow rate 10ml / min), normal pressure reaction.

Embodiment 3

[0025] Add 1g of Pd / AC (Pd mass content 2%) catalyst into the gas-phase catalytic hydrodechlorination reaction device, H 2 In the atmosphere, the temperature was raised from room temperature to 350°C over 2h, and the online reduction was carried out at 350°C for 2h. Then lower the temperature to 250°C, switch to reaction gas, at the volume ratio H 2 : HCFC-31=4:1 (total flow rate 10ml / min), normal pressure reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com