Microwave extraction separation and purification method of pea polysaccharide

A technology for separation and purification of peas, which is applied in the field of microwave extraction, separation and purification of pea polysaccharides, can solve the problems of low average extraction rate and purity, limited application of pea polysaccharides, and few methods for extraction, separation and purification of pea polysaccharides, and achieves the effect of improving the purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

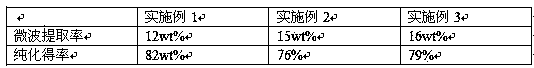

Embodiment 1

[0012] (1) Take 500g of fresh peas, and crush them with a grinder; (2) Extract the crushed peas with 20wt% ethanol water with a solid-liquid ratio of 1:5, microwave power of 200w, and microwave The extraction time is 3 hours, and the number of extractions is 3 times; (3) After the extraction, the extract is centrifuged at a speed of 4000 rpm for 20 minutes, and the upper supernatant is collected after centrifugation; (4) The supernatant is concentrated, Concentrate until the weight of the concentrate is 20% of the weight of the original supernatant, and after concentration, cool the concentrate to room temperature; (5) pass the concentrate through D3520 macroporous adsorption resin, the sample loading speed is 1.5BV / h, and the elution speed is optimal 2BV / h, collect the effluent, concentrate the effluent until pea crude polysaccharide is obtained; (6) purify the pea crude polysaccharide with ethanol, the weight ratio of ethanol to crude polysaccharide is 1:3, after purification...

Embodiment 2

[0014] (1) Take 300g of fresh peas, and crush them with a grinder; (2) Extract the crushed peas with 20wt% ethanol water with a solid-liquid ratio of 1:7, microwave power of 200w, and microwave The extraction time is 3 hours, and the number of extractions is 3 times; (3) After the extraction, the extract is centrifuged at a speed of 4000 rpm for 20 minutes, and the upper supernatant is collected after centrifugation; (4) The supernatant is concentrated, Concentrate until the weight of the concentrate is 20% of the weight of the original supernatant, and after concentration, cool the concentrate to room temperature; (5) pass the concentrate through D3520 macroporous adsorption resin, the loading speed is preferably 2BV / h, and the elution speed is preferably 1.5BV / h, collect the effluent, concentrate the effluent until pea crude polysaccharide is obtained; (6) purify the pea crude polysaccharide with ethanol, the weight ratio of ethanol to crude polysaccharide is 1:5, and purify ...

Embodiment 3

[0016] (1) Take 400g of fresh peas, and crush them with a grinder; (2) Extract the crushed peas with 20wt% ethanol water with a solid-liquid ratio of 1:10, microwave power of 200w, and microwave The extraction time is 3 hours, and the number of extractions is 3 times; (3) After the extraction, the extract is centrifuged at a speed of 4000 rpm for 20 minutes, and the upper supernatant is collected after centrifugation; (4) The supernatant is concentrated, Concentrate until the weight of the concentrate is 20% of the weight of the original supernatant, and after concentration, cool the concentrate to room temperature; (5) pass the concentrate through D3520 macroporous adsorption resin, the loading speed is preferably 2BV / h, and the elution speed is preferably 2BV / h, collect the effluent, concentrate the effluent until pea crude polysaccharide is obtained; (6) purify the pea crude polysaccharide with ethanol, the weight ratio of ethanol to crude polysaccharide is 1:4, and purify t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com