Preparation method for oil and water separation filter paper for naphtha and diesel oil

A technology of oil-water separation, gasoline and diesel oil, applied in paper, papermaking, physical treatment of paper, etc., can solve the problems of high energy consumption, long preparation cycle, complicated operation process, etc., and achieve low environmental pollution, high recycling rate and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be further described below in combination with specific examples.

[0037] The invention adopts n-hexane solution of octadecyl trichlorosilane as a hydrophobizing treatment reagent. The preparation method of oil-water separation filter paper is carried out as follows:

[0038] (1) Preparation of hydrophobization solution: Take 13 μL of Sigma’s octadecyltrichlorosilane and 10 mL of Aladdin’s n-hexane solution and mix evenly at room temperature;

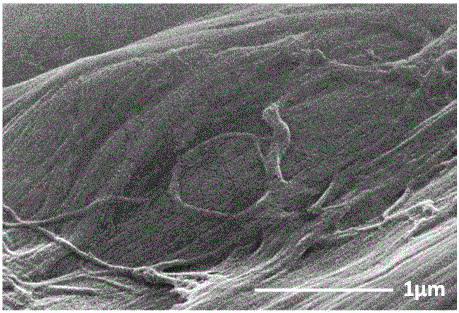

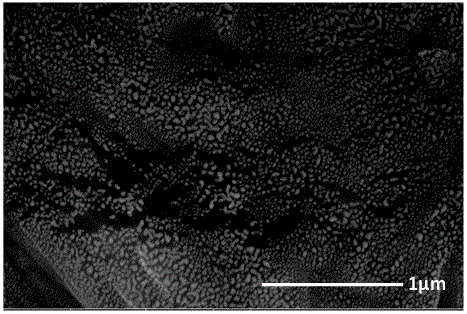

[0039] (2) Modification of filter paper: Soak No.1 filter paper of Whatman Company with a diameter of 9 cm in the above-mentioned hydrophobizing solution for 5 minutes at room temperature, take it out, put it into a clean constant temperature drying oven at 40 ° C, and heat and dry it for 5 minutes. That is, hydrophobic and lipophilic filter paper is obtained;

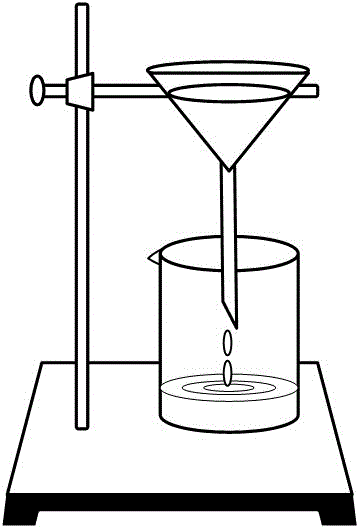

[0040] (3) Filtration performance test of hydrophobic and lipophilic filter paper: add ultrapure water to a small amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com