25%-thickness main airfoil for megawatt wind turbine blade

A wind turbine blade, megawatt-level technology, applied in the field of 25% thick main airfoil, can solve the problems of large absolute value of moment coefficient and high sensitivity factor, achieve high Reynolds number characteristics, improve utilization coefficient, and large lift-to-drag ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

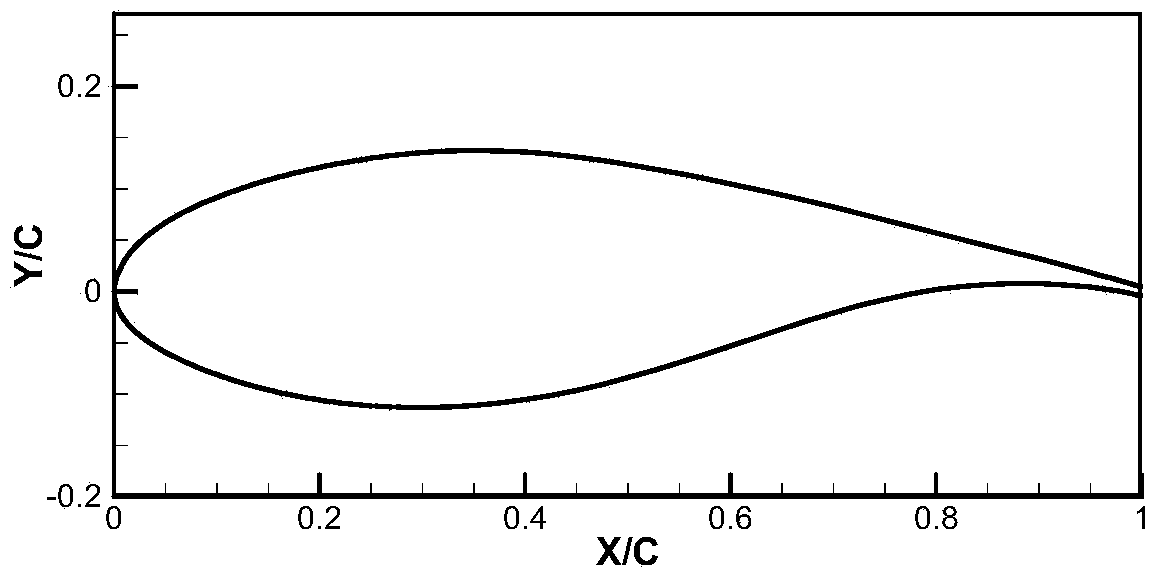

[0040] This embodiment is a main airfoil with a thickness of 25% for megawatt-class wind turbine blades.

[0041] refer to figure 1 , present embodiment is that the NPU-WA-252 airfoil of wind turbine proposed for the design of large wind turbine blade is the design target, and the main design indicators of large wind turbine blade are as follows:

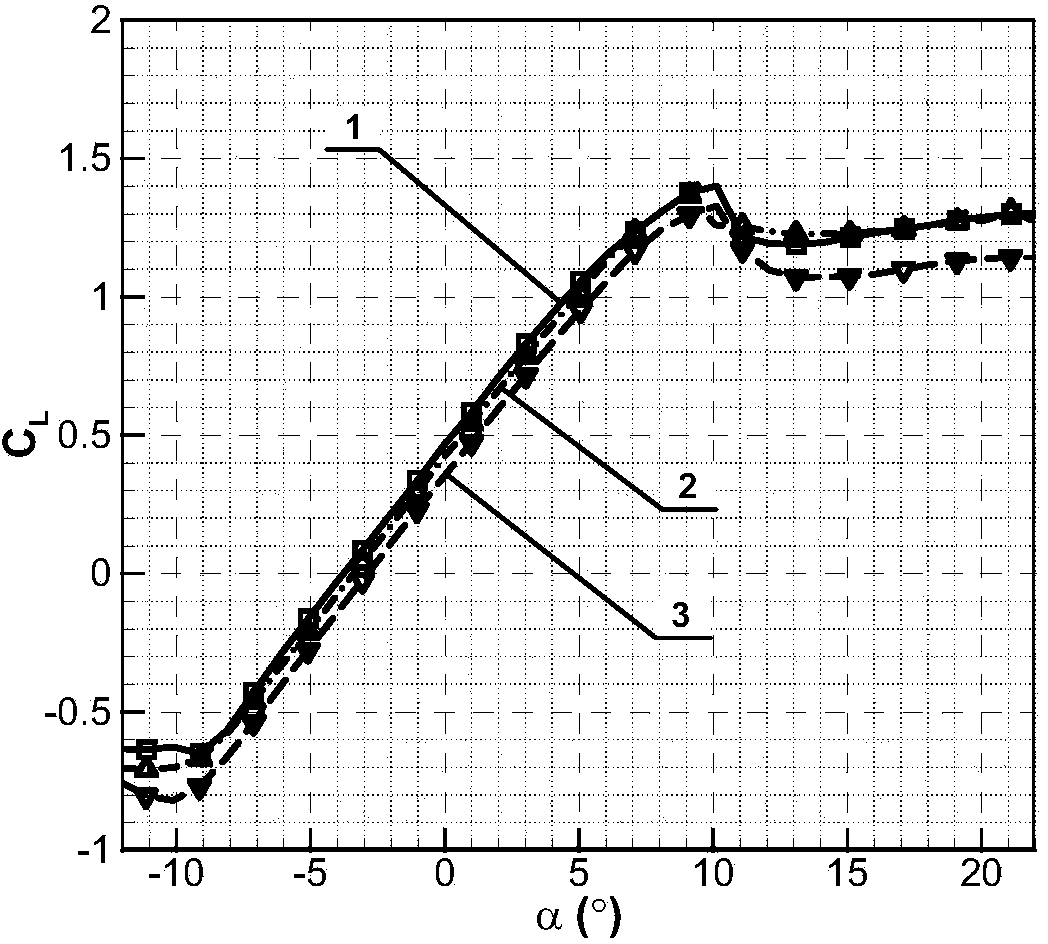

[0042] The design lift coefficient is 1.2;

[0043] The design angle of attack is 6 degrees;

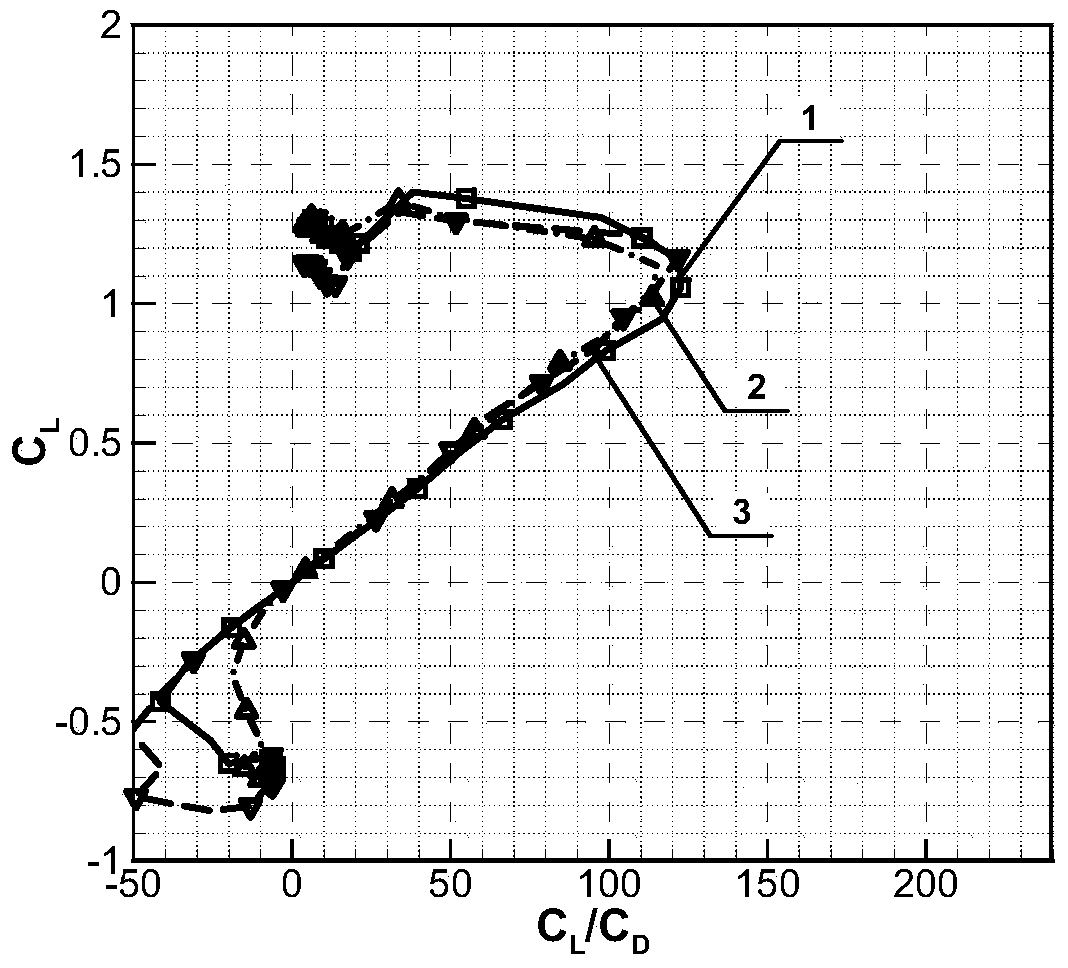

[0044] The design Reynolds number is 6.0×10 6 , under high Reynolds number and high lift design conditions, the NPU-WA-252 airfoil is required to have a higher lift-to-drag ratio than other similar airfoils, and to maintain a similar lift-to-drag ratio to the NPU-WA-250 airfoil; in Reynolds Number below 1.5×10 6 In non-design conditions, the lift-to-drag ratio is kept comparable to that of traditional airfoils;

[0045] The NPU-WA-252 airfoil is required to have a higher lift coefficient than the traditional airfoil;

[0046] The mom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com