All-fiber magnetic field sensor

A magnetic field sensor and all-fiber technology, which is applied in magnetic-optical equipment for magnetic field measurement, the size/direction of the magnetic field, etc., can solve the problems of micro-nano optical fiber fragility, difficult coating, troublesome grating production, etc., and achieve simple production , improved sensitivity, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

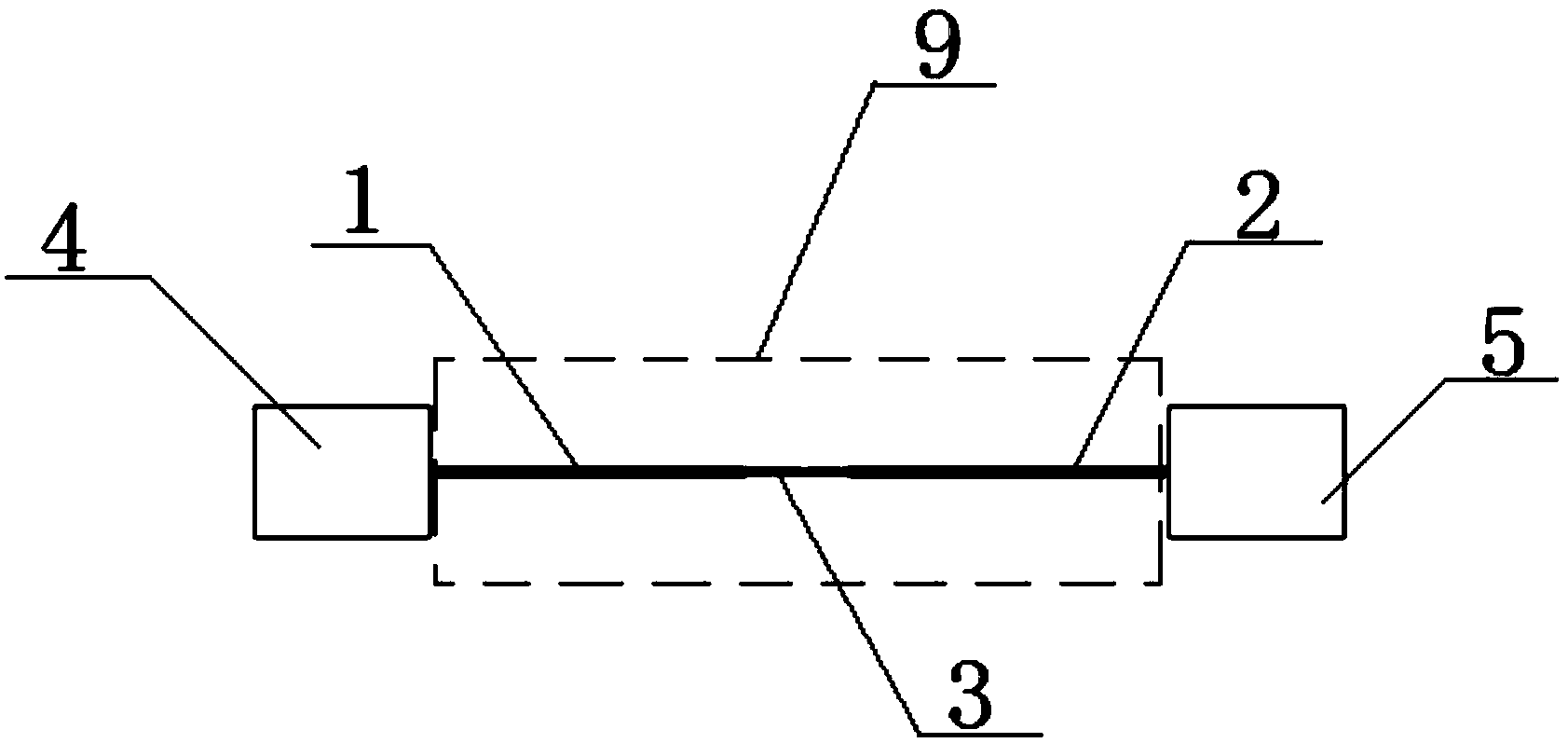

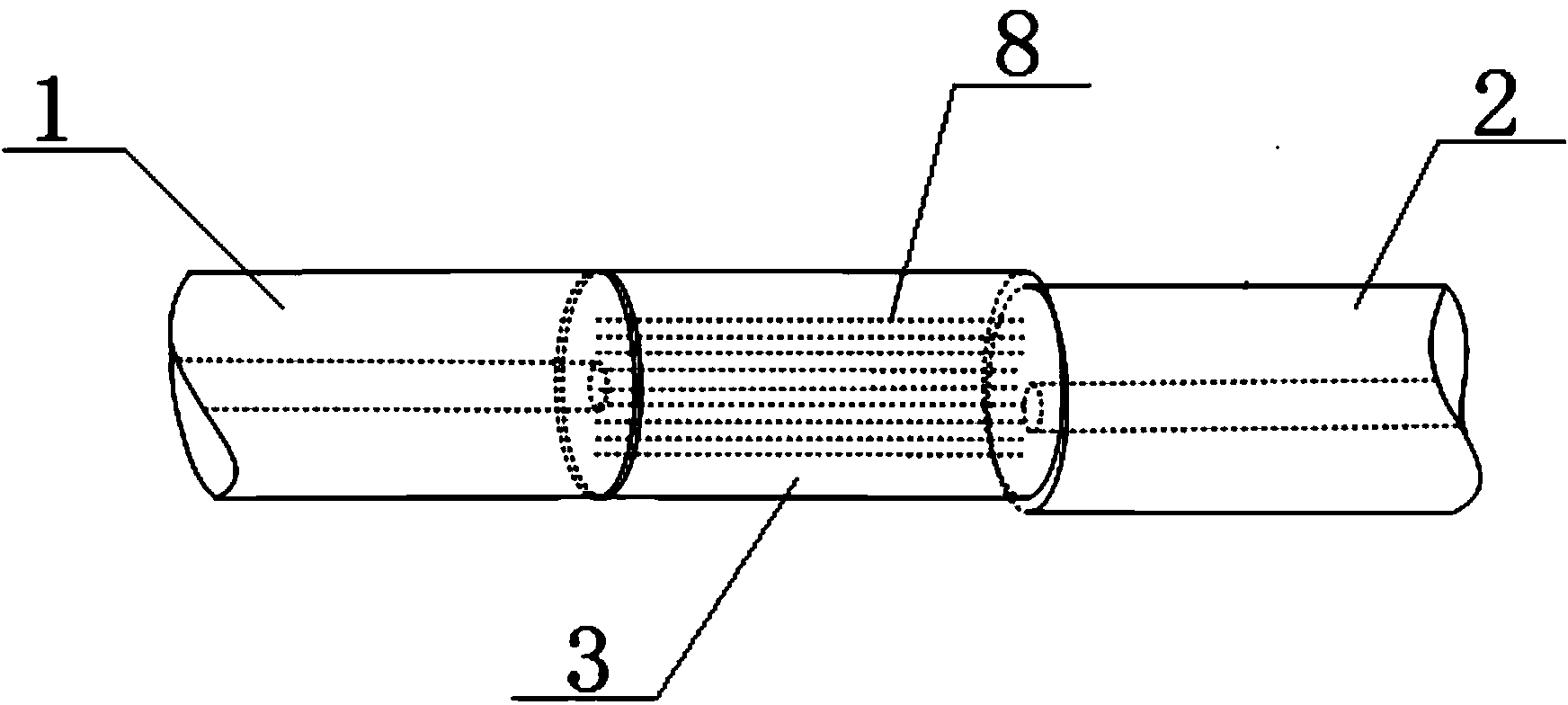

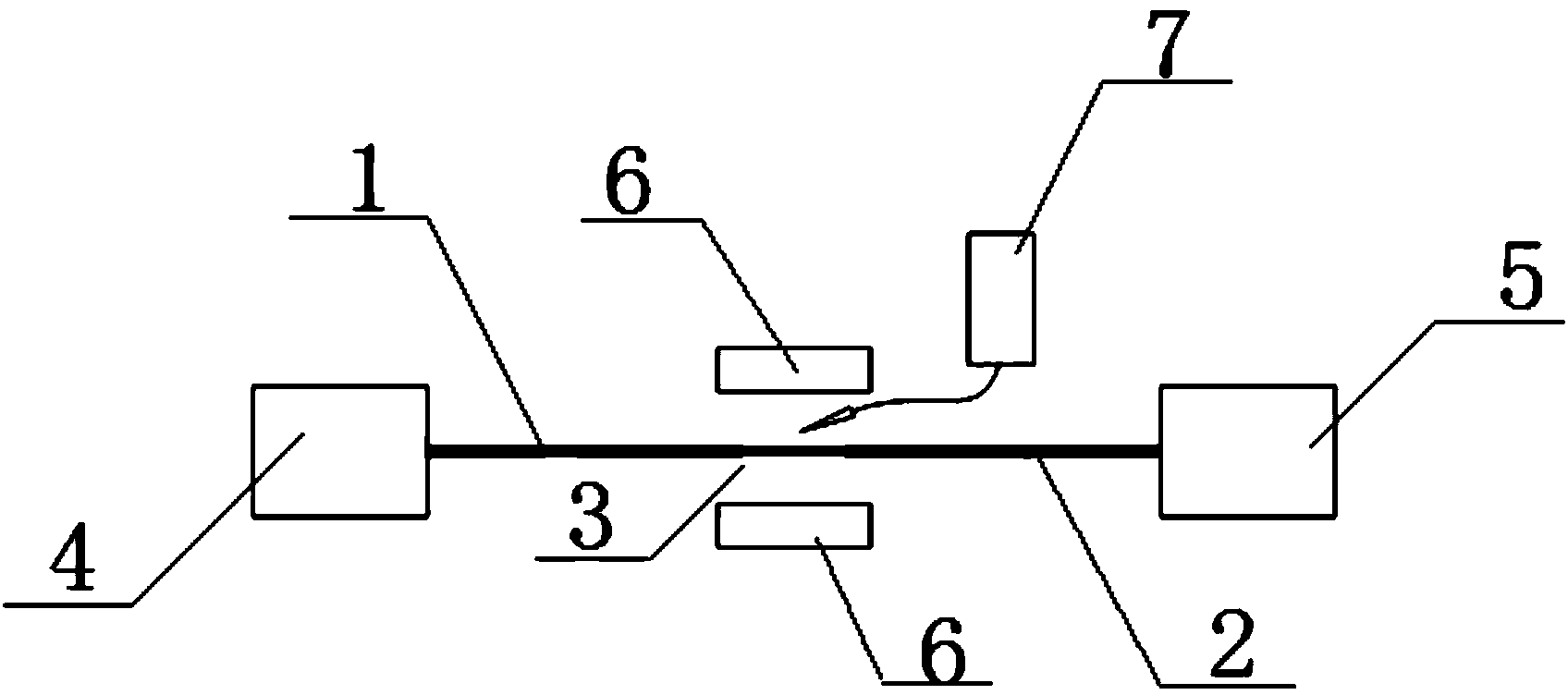

[0029] An all-fiber type magnetic field sensor provided in this embodiment has a structure such as Figure 1-3 As shown, it includes a broadband light source 4 connected in sequence, a sensor head 9 and a spectrometer 5, and the sensor head 9 is formed by fusion splicing a photonic crystal fiber 3 of no more than 1 cm and a single-mode fiber with a core diameter of 2-12 μm, wherein :

[0030] The photonic crystal fiber 3 has a hollow air hole structure, and the air hole is filled with a magnetic fluid 8 containing nano-ferromagnetic particles by high-pressure extrusion. The single-mode fiber includes a first single-mode fiber 1 and a second single-mode fiber 2. One end of the photonic crystal fiber 3 filled with magnetic fluid 8 is fused with the first single-mode optical fiber 1 through a fiber fusion splicer, and the other end is eccentrically fused with the second single-mode optical fiber 2 through a fiber fusion splicer to form a single-fiber embedded Mach Zender interfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com