Porous VO2 nano-wire as well as preparation method and application thereof

A nanowire and VO2 technology, applied in the field of nanomaterials and electrochemistry, can solve problems such as poor cycle performance, restricted application, low electronic conductivity and ionic conductivity, and achieve low equipment requirements, simple process, and excellent cycle characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

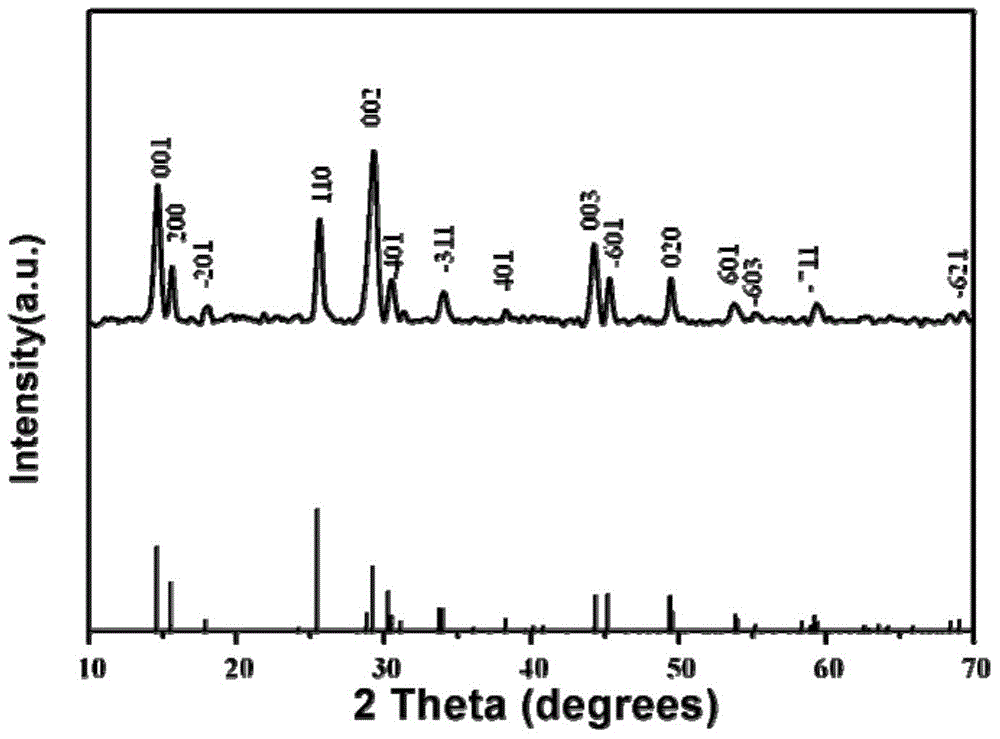

[0032] Porous VO 2 Nanowire and its preparation method, it comprises the following steps:

[0033] 1) Measure 80mL of deionized water in a beaker and keep it in a water bath at 80°C under stirring;

[0034] 2) Weigh 1.04g of ammonium metavanadate powder and add it to the beaker in the previous step 1), and continue to stir;

[0035] 3) After 0.5h, take out the beaker and stir to cool;

[0036] 4) After cooling to room temperature, slowly add hydrochloric acid into the beaker, continue stirring until pH=1-2, and keep stirring for 2h;

[0037] 5) The solution obtained in the above step 4) was transferred into a 100mL reaction kettle, reacted under 180°C for 7 days, took out the reaction kettle, and was naturally cooled to room temperature;

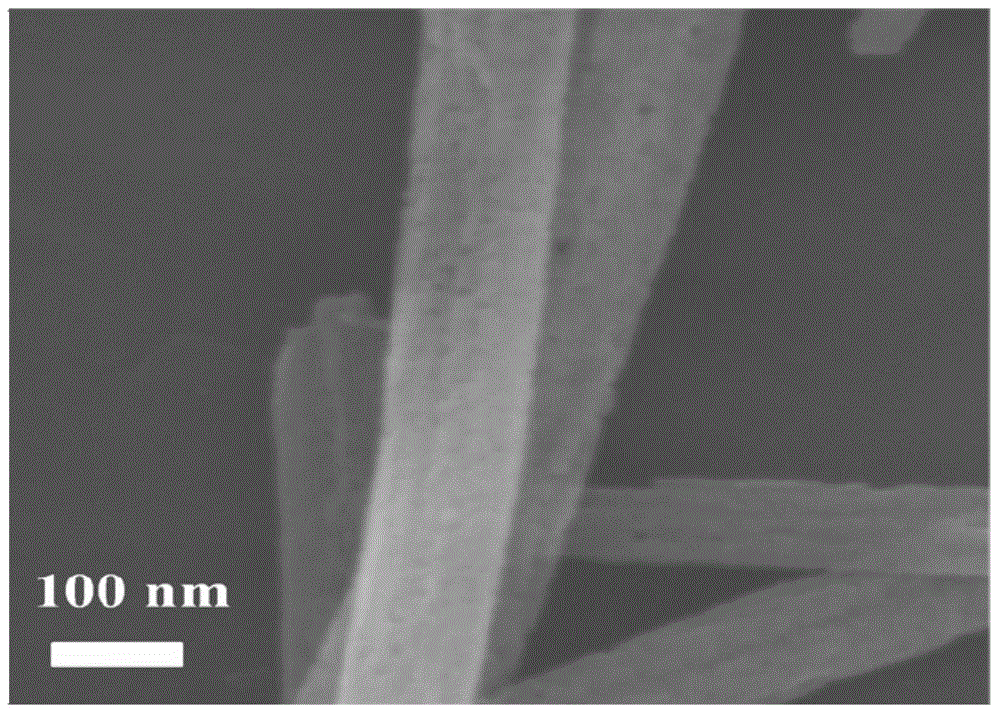

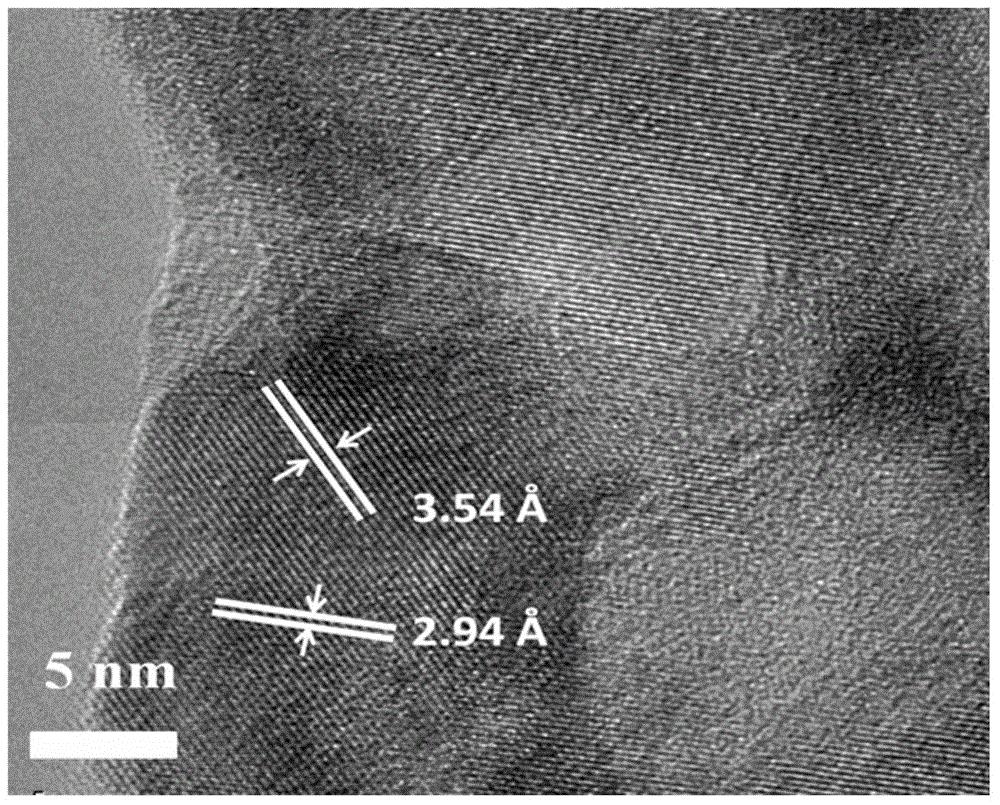

[0038] 6) The resulting product NH 4 V 3 O 8 The nanowires were put into plastic tubes and dried in a drying oven at 80 °C, such as Figure 4 A and Figure 4 as shown in B;

[0039] 7) The dried NH 4 V 3 O 8 The nanowires were tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com