Rejection device and plastic bottle blowing-filling-sealing integrated machine with the same

A technology of rejecting device and bottle holder, applied in sorting and other directions, can solve the problems of high cost, inconvenient production and debugging, complicated structure of rejecting device, etc., and achieve the effects of convenient production and debugging, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

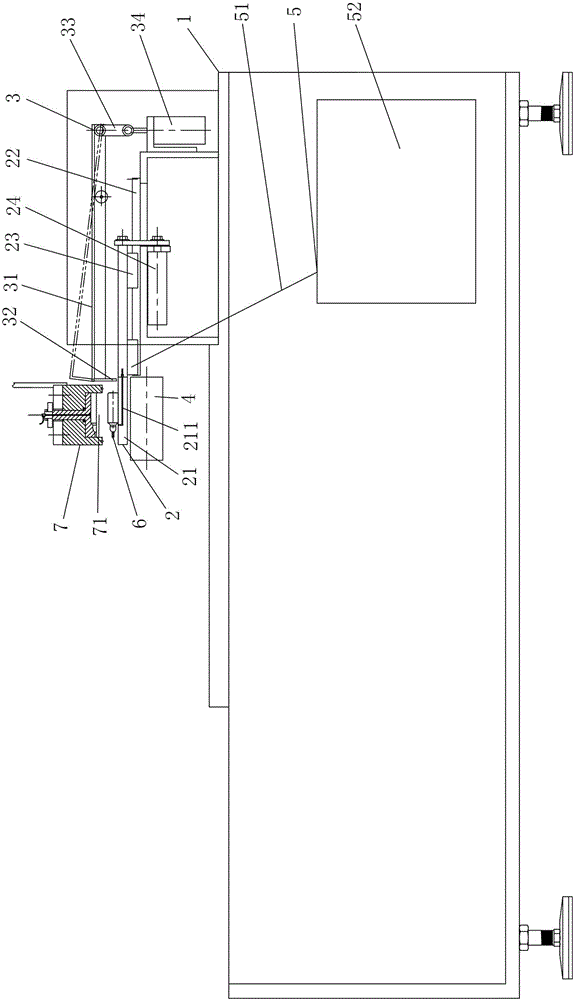

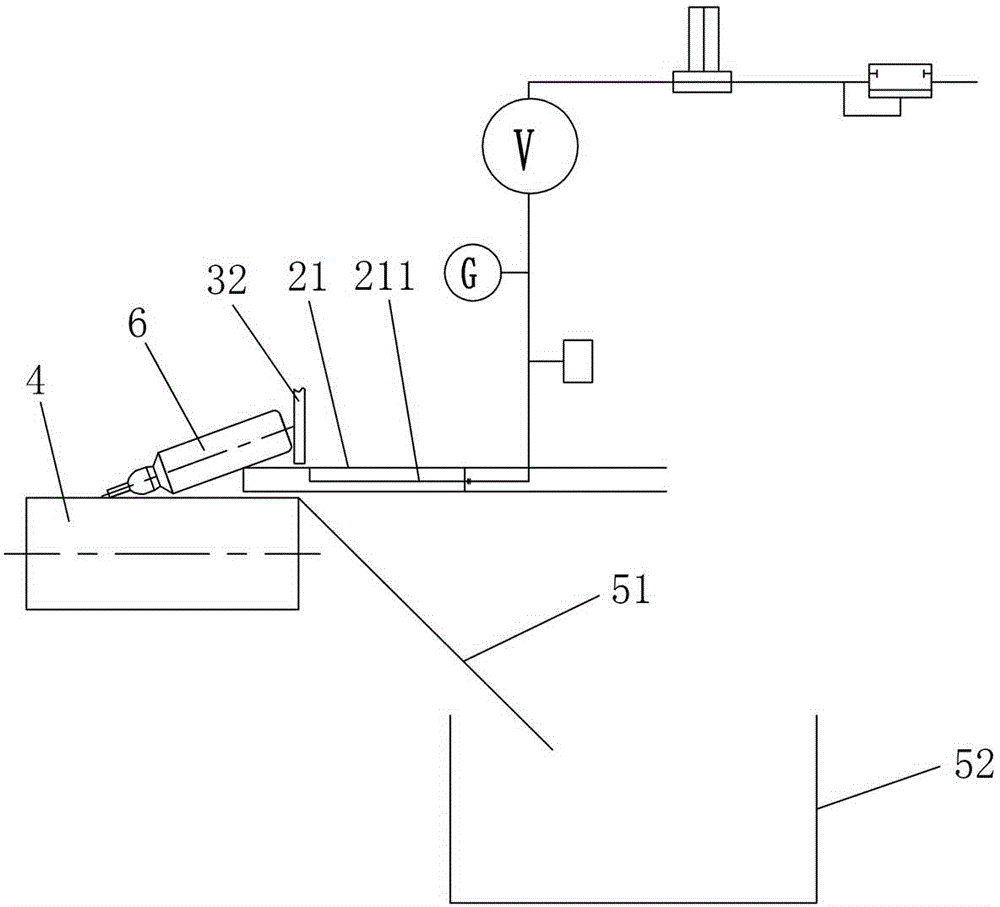

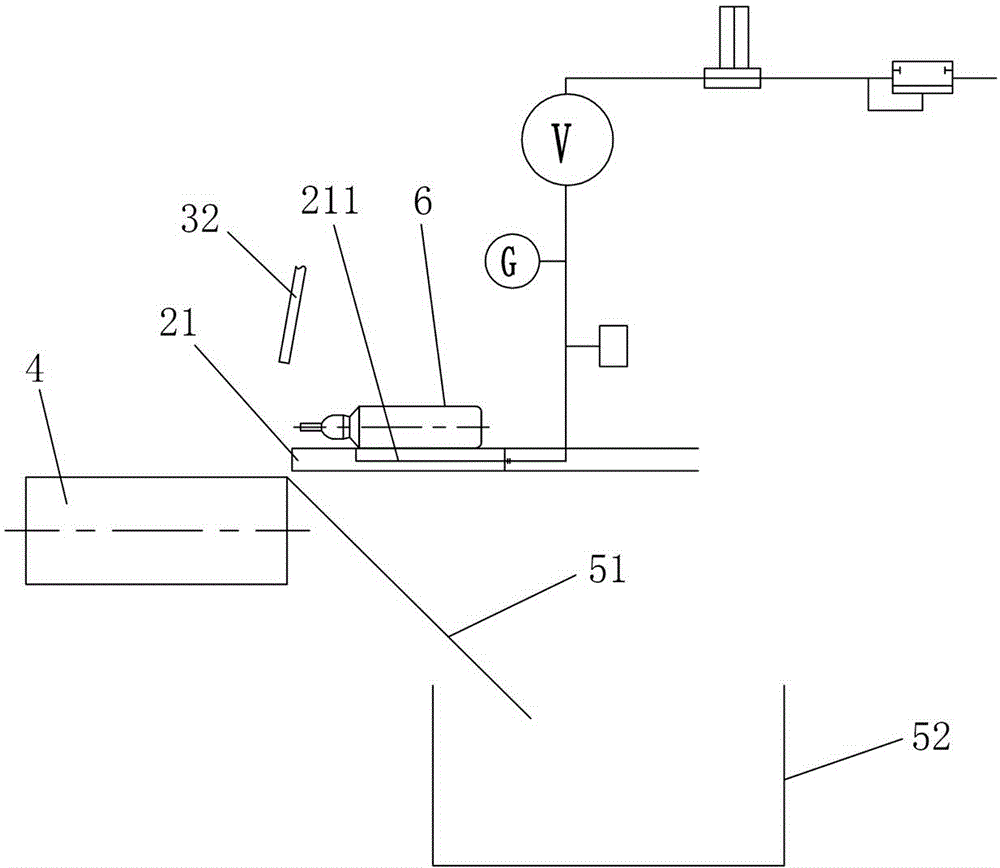

[0024] Such as Figure 1 to Figure 4 As shown, the rejecting device of the present invention includes a frame 1 and a bottle supporting mechanism 2 installed on the frame 1, a bottle blocking mechanism 3, a qualified bottle conveying mechanism 4, and a waste bottle conveying mechanism 5. The bottom of the bottle mechanism 3 can carry the bottle card 6 to reciprocate on both sides of the bottle stop mechanism 3. When the bottle support mechanism 2 moves, the bottle stop mechanism 3 can move the bottle card 6 to any side of the bottle stop mechanism 3 , can also block the bottle card 6 and make it fall from the bottle supporting mechanism 2. The rejecting device of the present invention has the advantages of simple structure, low cost, and convenient production and debugging. The bottle card 6 that has completed the leak detection is p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap