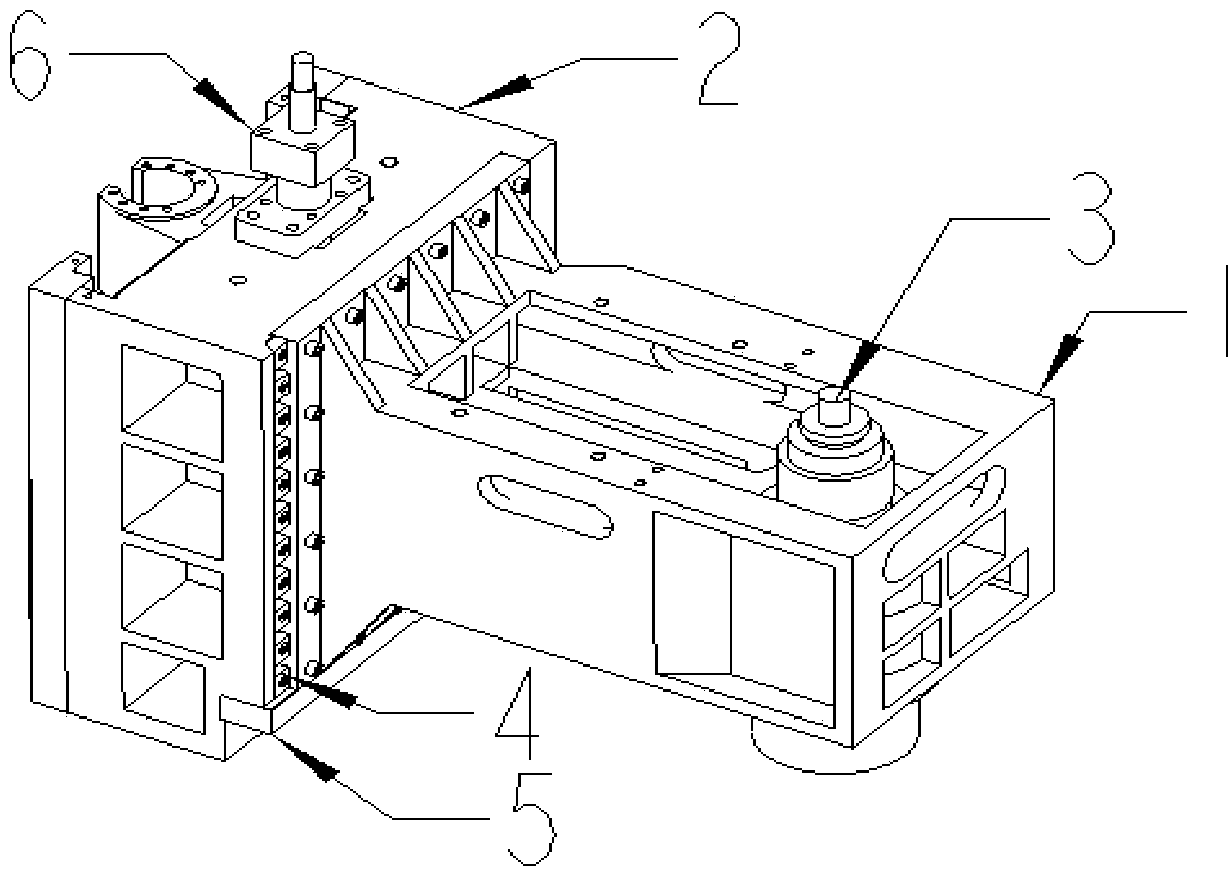

Split type vertical machining center spindle box structure

A vertical machining center and machining center technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of increasing the assembly process, inconvenient machine tool transportation, increasing the height of the machine tool, etc., to achieve compact structure, Ease of replacement and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

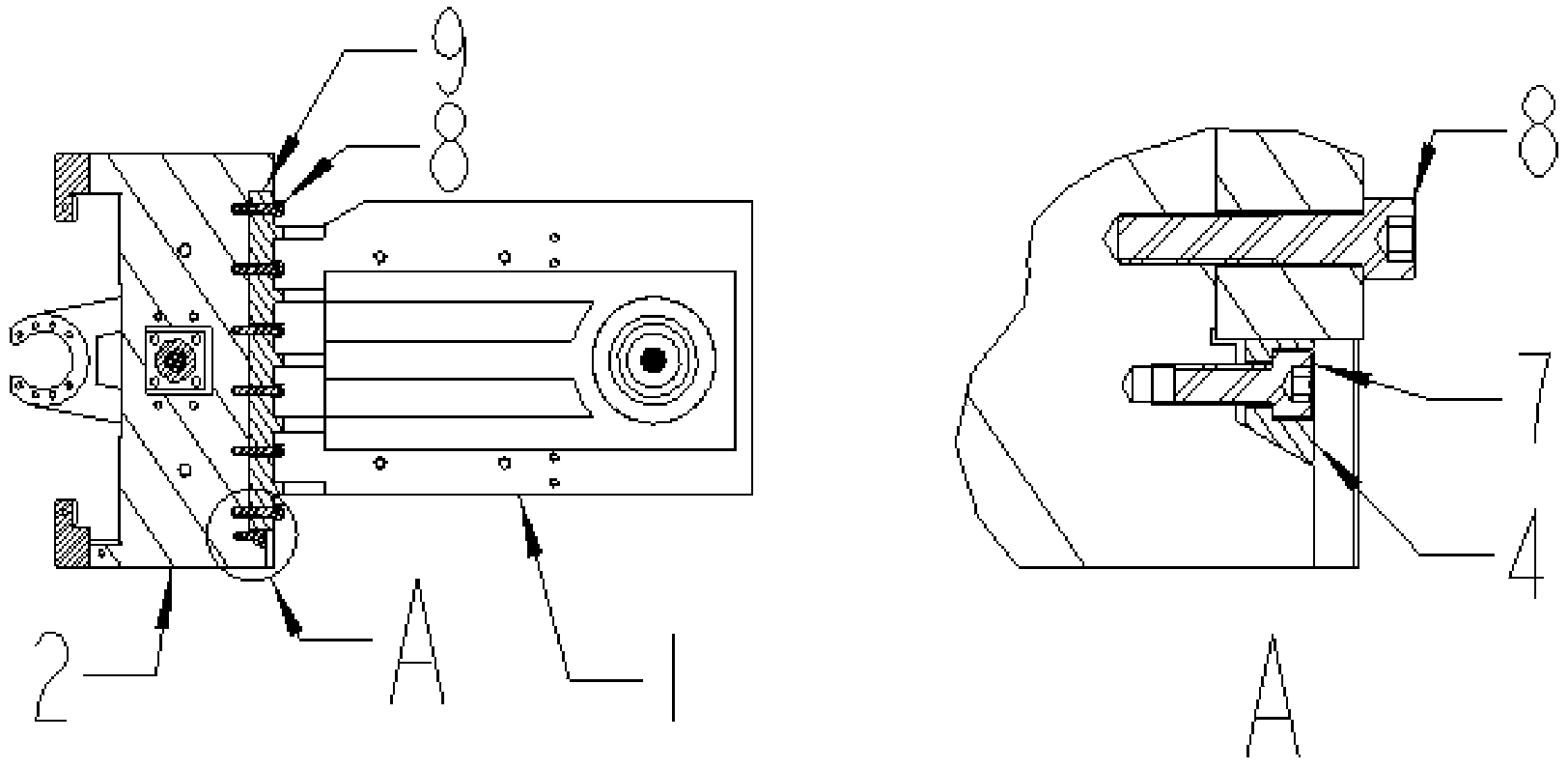

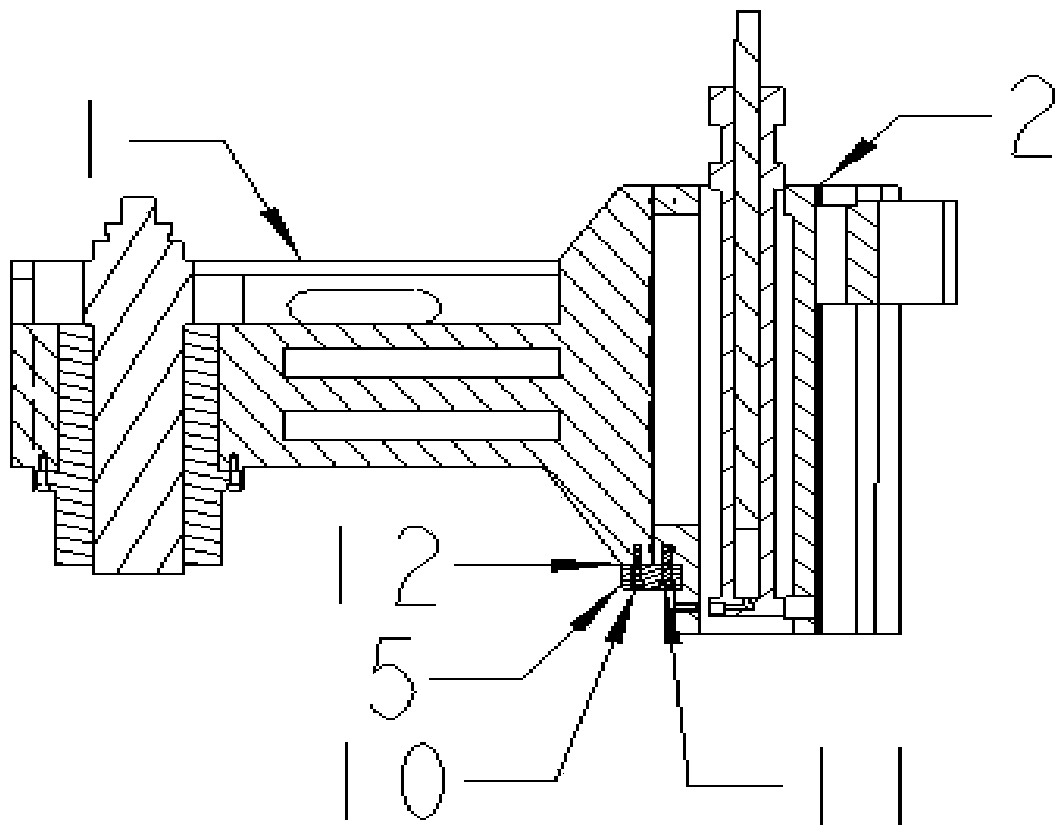

[0010] The headstock of the present invention adopts a split structure, which is divided into a headstock 1 and a headstock interface part 2. The headstock 1 and the headstock interface part 2 are connected by fixing bolts 8, and the left and right directions are pressed to the side reference by a wedge-shaped pressing block 4. 9. In the up and down direction, by installing the fixing screw 10 on the baffle plate 5, the headstock 1 is tightened to the bottom datum 12 to ensure the accuracy of the connection. The installation position of the nitrogen balance device 6 is designed on the headstock interface part 2, and the nitrogen balance device 6 is built inside the headstock interface part.

[0011] When the column guide rail is changed from a sliding guide rail to a rolling guide rail, it is only necessary to replace the headstock interface parts with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com