Rectangular taper metal bin blockage clearing equipment and use method thereof

A metal material and blockage removal technology, which is applied in containers, packaging, transportation and packaging, etc., can solve the problems of hindering the material in the warehouse from sliding down, the material in the warehouse cannot be discharged out of the warehouse, and the high viscosity material is difficult to handle, etc., so as to improve the quality of beneficiation. and production efficiency, relieve personal injury, and have significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

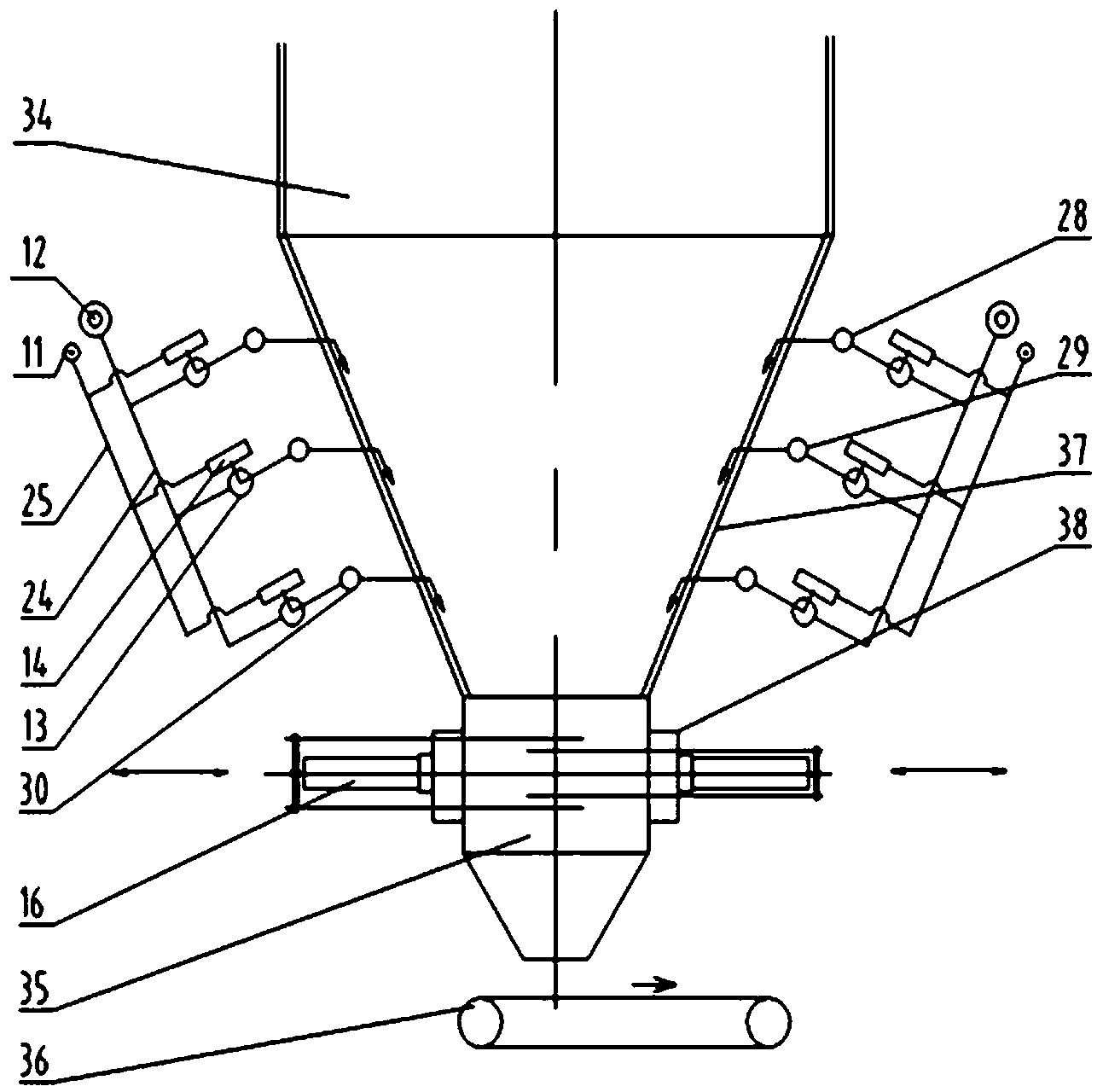

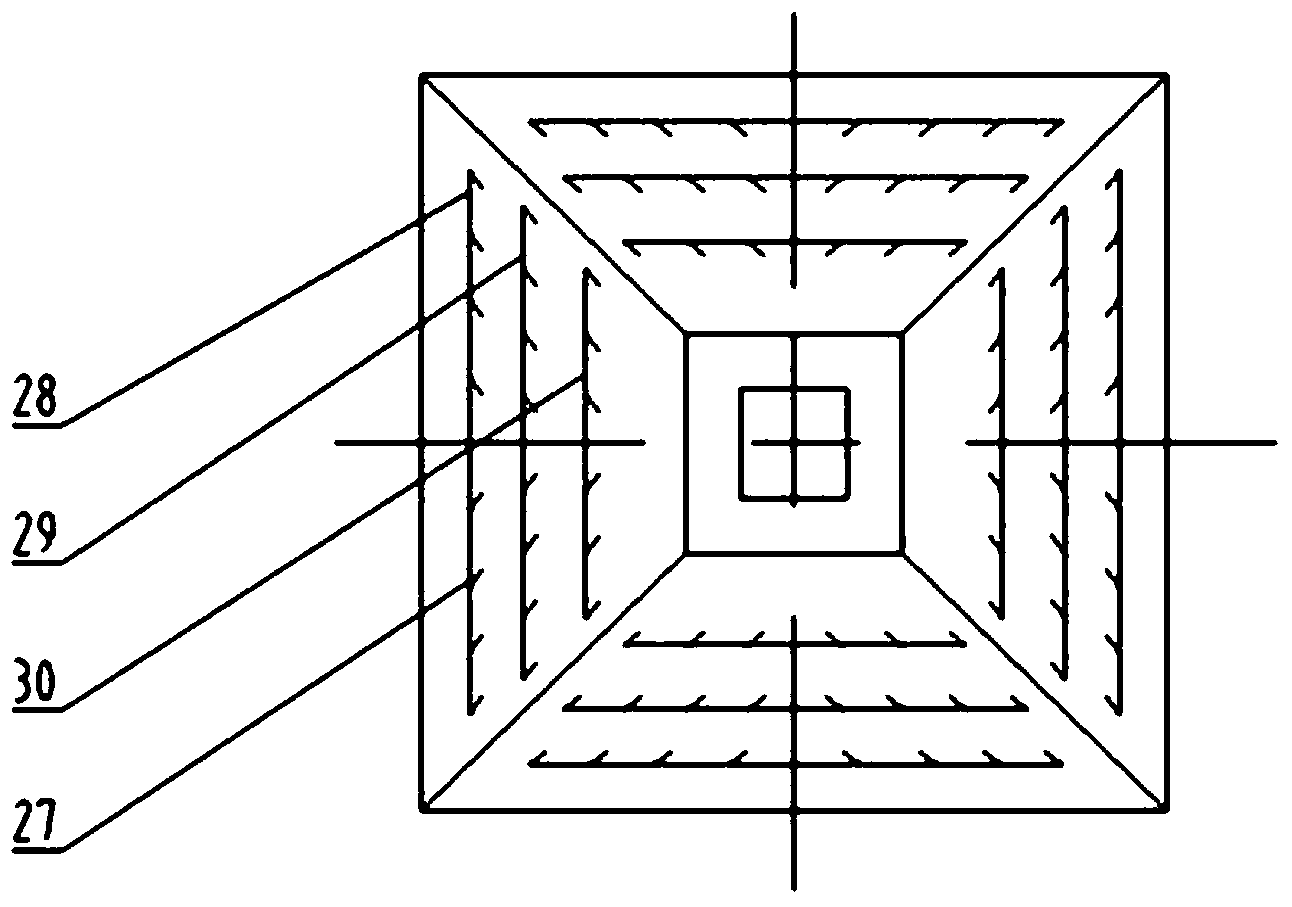

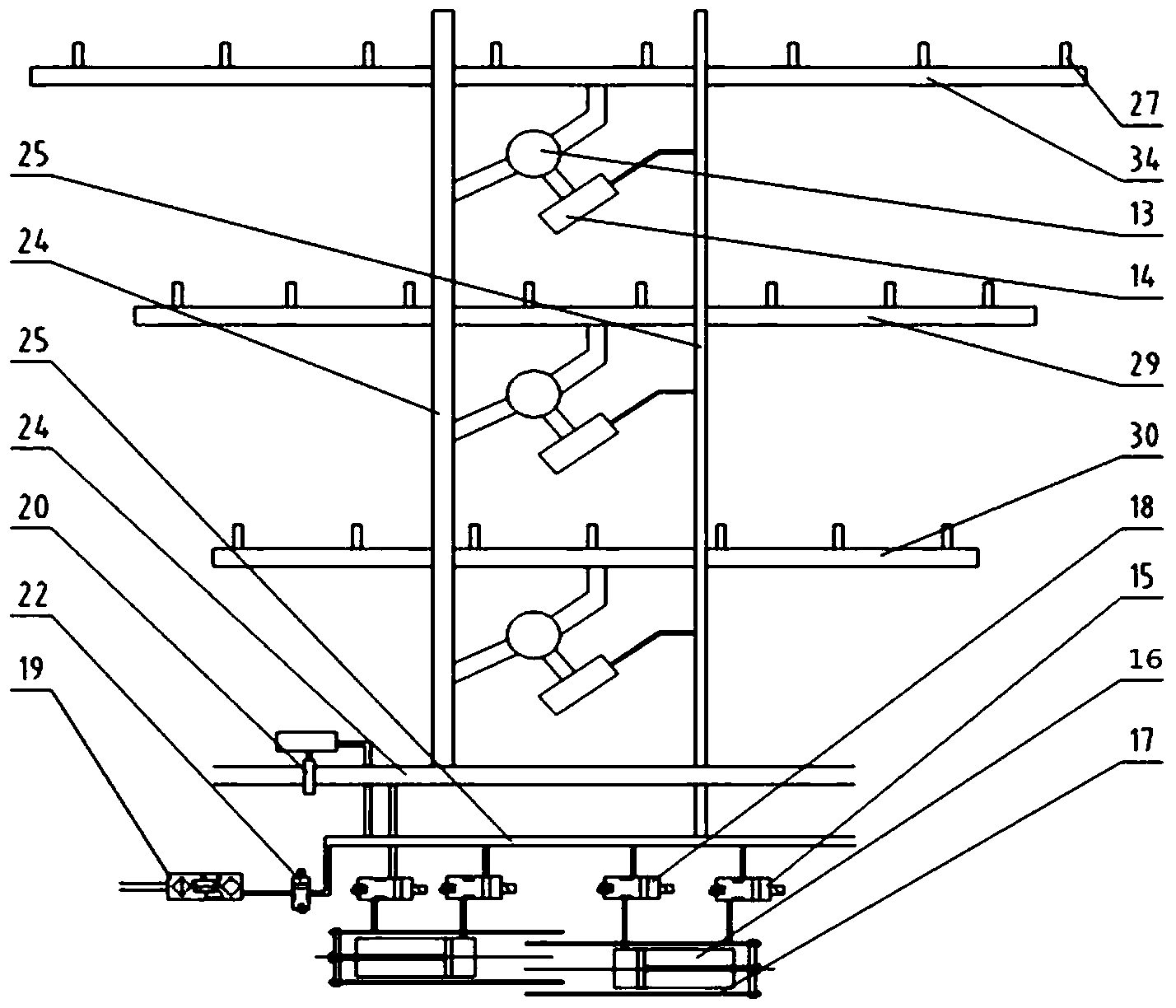

[0021] In order to further describe the present invention, the clogging equipment and usage method of the rectangular-conical metal silo of the present invention will be described in more detail below in conjunction with the accompanying drawings and examples.

[0022] On the four cone walls 37 of the mine bin 34, each cone wall is equipped with three groups of flow-aiding nozzle groups, and the first layer of nozzle groups 30 (lowest layer) is equipped with 4 flow-aiding nozzles 27, The second layer of nozzle group 29 is equipped with 6 flow aid nozzles 27, the third layer of nozzle group 28 is equipped with 8 flow aid nozzles 27, four sides, the first layer has 16 flow aid nozzles, the second layer There are 24 flow aid nozzles 27 in total, and 32 flow aid nozzles 27 in the third layer. Each nozzle group is provided with an electro-pneumatic butterfly valve 13 and a first electro-pneumatic actuator 14, and each cone has three electro-pneumatic butterfly valves 13. Each nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com