Scale inhibitor used for inhibiting formation of calcium sulfate scale and preparation method thereof

A technology of calcium sulfate scale and scale inhibitor, used in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

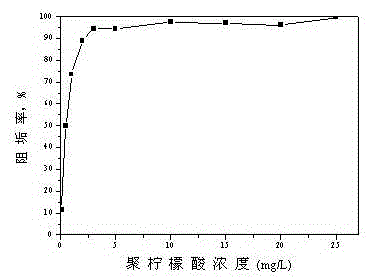

Image

Examples

Embodiment 1

[0039] A scale inhibitor used to inhibit the formation of calcium sulfate scale, that is, polycitric acid obtained through condensation polymerization reaction using citric acid as raw material.

[0040] The above-mentioned preparation method for suppressing the scale inhibitor that calcium sulfate scale forms, specifically comprises the steps:

[0041] (1) Add 20 mL of solvent and 4.0 g of citric acid into the reactor, stir and mix evenly to obtain a solution;

[0042] Described solvent is tetrahydrofuran, and its consumption is calculated as 200g / L by the concentration of the citric acid finally formed;

[0043] (2) Control the dropping rate to 0.05mL / min, add 2.2mL catalyst to the solution obtained in step (1), stir and mix evenly, then heat to reflux state to carry out condensation polymerization for 4h;

[0044] Described catalyzer is concentrated sulfuric acid, and its consumption is calculated by mass ratio, namely catalyzer: citric acid is 1:1;

[0045] (3), adjust t...

Embodiment 2

[0048] A scale inhibitor used to inhibit the formation of calcium sulfate scale, that is, polycitric acid obtained through condensation polymerization reaction using citric acid as raw material.

[0049] The above-mentioned antiscalant for suppressing the formation of calcium sulfate scale, i.e. the preparation method of polycitric acid, specifically comprises the steps:

[0050] (1) Add 90mL of solvent and 1.8g of citric acid into the reactor, stir and mix evenly to obtain a solution;

[0051] Described solvent is tetrahydrofuran, and its consumption is calculated as 20g / L by the concentration of the citric acid finally formed;

[0052] (2) Control the dropping rate to 0.5mL / min, add 3.9mL of catalyst to the solution obtained in step (1), stir and mix evenly, then heat to reflux state to carry out condensation polymerization reaction for 24h to obtain the reaction solution;

[0053] Described catalyzer is the concentrated sulfuric acid, and its consumption is calculated by m...

Embodiment 3

[0057] A scale inhibitor used to inhibit the formation of calcium sulfate scale, that is, polycitric acid obtained through condensation polymerization reaction using citric acid as raw material.

[0058] The above-mentioned antiscalant for suppressing the formation of calcium sulfate scale, i.e. the preparation method of polycitric acid, specifically comprises the steps:

[0059] (1) Add 40 mL of solvent and 4.0 g of citric acid into the reactor, stir and mix evenly to obtain a solution;

[0060] Described solvent is tetrahydrofuran, and its consumption is calculated as 100g / L by the concentration of the citric acid finally formed;

[0061] (2) Add 4.5mL catalyst to the solution obtained in step (1) by controlling the dropping rate to 0.25mL / min, stir and mix evenly, then heat to reflux state to carry out condensation polymerization for 12 hours to obtain a reaction solution;

[0062] Described catalyzer is the concentrated sulfuric acid, and its consumption is calculated by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com