Method for preparing sucrose abietate

A technology of sucrose rosin acid ester and rosin, which is applied in the field of surfactant preparation, can solve the problems that sucrose rosin acid ester cannot meet the food additive standard requirements, damage, memory loss, etc., achieve mild reaction conditions, and reduce trace metal elements such as aluminum content, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

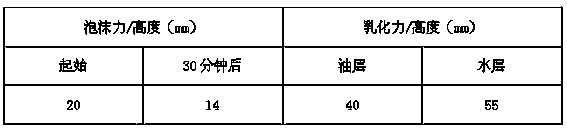

Examples

Embodiment 1

[0013] A preparation method of rosin acid sucrose ester, the method comprising the following preparation steps:

[0014] A. Put 10Kg of raw turpentine into a reactor previously equipped with 15Kg of an acidic solution with a pH value of 2, then add tartaric acid to it to make the concentration reach 0.5%, stir evenly, then heat to 100°C for 20 minutes of heat preservation reaction, and the reaction is over Finally, stand still and separate to obtain refined rosin;

[0015] B. Mix the rosin and sucrose prepared in step A evenly at a mass ratio of 3:1, then add glycerin accounting for 50% of the mass of rosin and sucrose, mix evenly, and heat the mixture to 150°C for reflux reaction for 2 hours ;

[0016] C. After the reflux reaction is finished, the product obtained by the reaction is distilled to evaporate the water contained therein, then dissolved and purified with acetone, filtered, the filtrates are combined, and the acetone is evaporated to dryness to obtain the sucrose ...

Embodiment 2

[0019] A preparation method of rosin acid sucrose ester, the method comprising the following preparation steps:

[0020] A. Put 10Kg of raw turpentine into a reactor previously equipped with 18Kg of an acidic solution with a pH value of 3, then add tartaric acid to it to make the concentration reach 0.6%, stir evenly, then heat to 102°C for 18 minutes of heat preservation reaction, after the reaction is over , standing and separating to obtain refined rosin;

[0021] B. Mix the rosin and sucrose prepared in step A at a molar ratio of 3:1 evenly, then add glycerin accounting for 50% of the mass of rosin and sucrose, mix evenly, and heat the mixture to 150°C for reflux reaction 2 Hour;

[0022] C. After the reflux reaction is finished, the product obtained by the reaction is distilled to evaporate the water contained therein, then dissolved and purified with acetone, filtered, the filtrates are combined, and the acetone is evaporated to dryness to obtain the sucrose abietic aci...

Embodiment 3

[0025] A preparation method of rosin acid sucrose ester, the method comprising the following preparation steps:

[0026] A. Put 10Kg of raw rosin into a reactor previously equipped with 20Kg of an acidic solution with a pH value of 4, then add tartaric acid to it to make the concentration reach 0.8%, stir evenly, then heat to 100°C for 15 minutes of heat preservation reaction, and the reaction is over Finally, stand still and separate to obtain refined rosin;

[0027] B. Mix the rosin and sucrose prepared in step A at a molar ratio of 3:1 evenly, then add glycerin accounting for 50% of the mass of rosin and sucrose, mix evenly, and heat the mixture to 150°C for reflux reaction 2 Hour;

[0028] C. After the reflux reaction is finished, the product obtained by the reaction is distilled to evaporate the water contained therein, then dissolved and purified with acetone, filtered, the filtrates are combined, and the acetone is evaporated to dryness to obtain the sucrose abietic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com