Ti-B-C-N ceramic coating and preparation method thereof

A ceramic coating, ti-b-c-n technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of poor coating performance, achieve good toughness, high-quality wear resistance, improve the overall The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

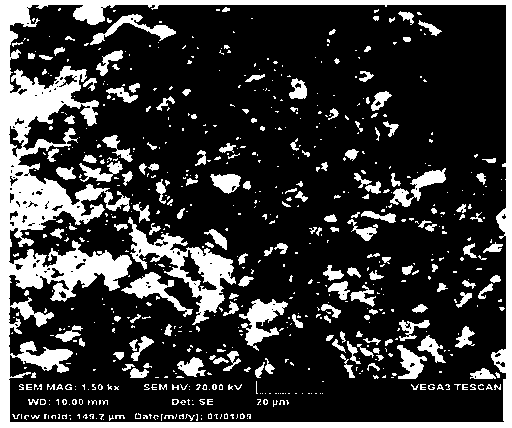

[0036] Example 1 prepares Ti-B-C-N composite coating on Q235 steel plate

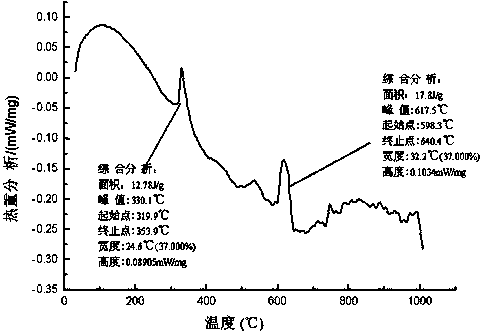

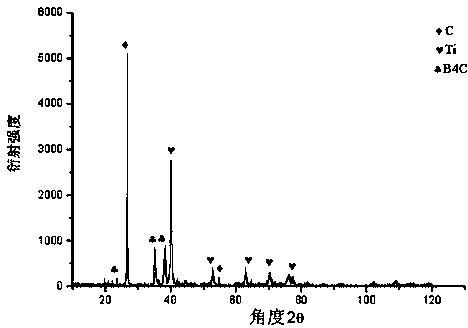

[0037] 1. Preparation of composite powder of Ti-B-C-N ceramic coating

[0038] (1) Combine 68g Ti powder, 17gB 4Put C powder, 6g of graphite powder and 10g of Co powder into a ball mill jar, the ball-to-material ratio is 3:1, add an appropriate amount of absolute ethanol, the ball mill speed is 200r / min, the ball mill time is 8h, and take out after the powder is evenly mixed;

[0039] (2) Dry the taken-out composite powder in a blast drying oven at 60°C;

[0040] (3) Add 3g of polyvinyl alcohol binder to the composite powder, mix well and put it on a tablet press for tableting at a pressure of 20MPa, and let stand for 5 minutes during tableting;

[0041] (4) Put the pressed block into a vacuum furnace and heat it to 600°C with a vacuum of 10 -4 MPa, keep warm for 2 hours and then cool down;

[0042] (5) Put the sintered block into a planetary ball mill for crushing, and sieve out a powder with a par...

Embodiment 2

[0054] 1. Preparation of composite powder of Ti-B-C-N ceramic coating

[0055] (1) Mix 101g Ti powder, 25gB 4 C powder, 9g of graphite powder and 15g of Co powder were put into a ball mill jar with a ball-to-material ratio of 4:1, an appropriate amount of absolute ethanol was added, the speed of the ball mill was 250r / min, and the ball milling time was 7h. After the powder was evenly mixed, it was taken out.

[0056] (2) Dry the taken out composite powder in a blast drying oven at 60°C;

[0057] (3) Add 5g of polyvinyl alcohol binder to the composite powder, mix well and put it on the tablet press for pressing

[0058] Tablets, the pressure is 20MPa, stand still for 5min when pressing;

[0059] (4) Put the pressed block into a vacuum furnace and heat it to 550°C with a vacuum of 10 -4 MPa, keep warm for 2 hours and then cool down;

[0060] (5) Put the sintered block into a planetary ball mill for crushing, and use a 300-mesh sieve to sieve the powder with a particle size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com