Method for quickly heating steam engine of gas engine combined cycle unit in cold state

A combined cycle unit and steam turbine technology, which is applied to steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of increasing the heat load of the condenser, heat consumption, and increasing the erosion of the valve core, so as to reduce the load of the single combustion engine , The effect of increasing the warm-up speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

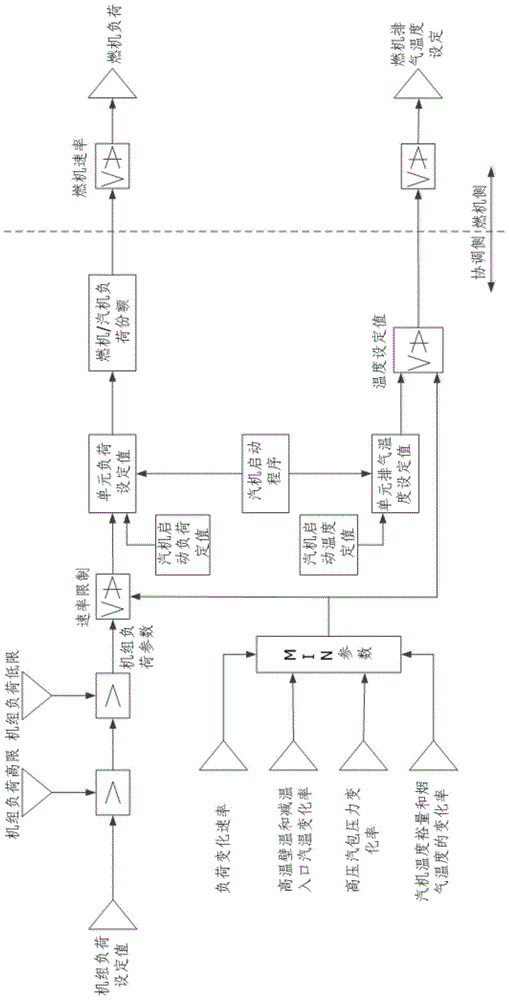

[0052] figure 1 Disclosed is the process of a medium-speed warm-up method for a steam turbine in a cold state of a gas turbine combined cycle unit in the prior art. like figure 1 As shown, the process of the steam turbine cold-state medium-speed warm-up method of the gas turbine combined cycle unit in the prior art is as follows:

[0053] Computer group load parameters. The process of calculating the load parameters of the unit includes: receiving the set value of the unit load, determining the upper limit of the unit load, and determining the lower limit of the unit load. The chiller load parameters are calculated based on the chiller load setpoint, chiller load high limit, and chiller load low limit.

[0054] Computes the MIN parameter. The MIN parameter is calculated based on the load change rate, the high temperature wall temperature change rate of the desuperheating inlet air temperature, the high pressure drum pressure change rate, the turbine temperature margin and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com