Rotary drum dryer internally provided with screen cloth

A dryer and screen technology, which is applied in the direction of dryers, drying, non-progressive dryers, etc., can solve the problems of uneven casting curtains, low drying efficiency, and rapid cylinder wear, etc. Achieve the effects of prolonging heat exchange time, improving drying efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and embodiments.

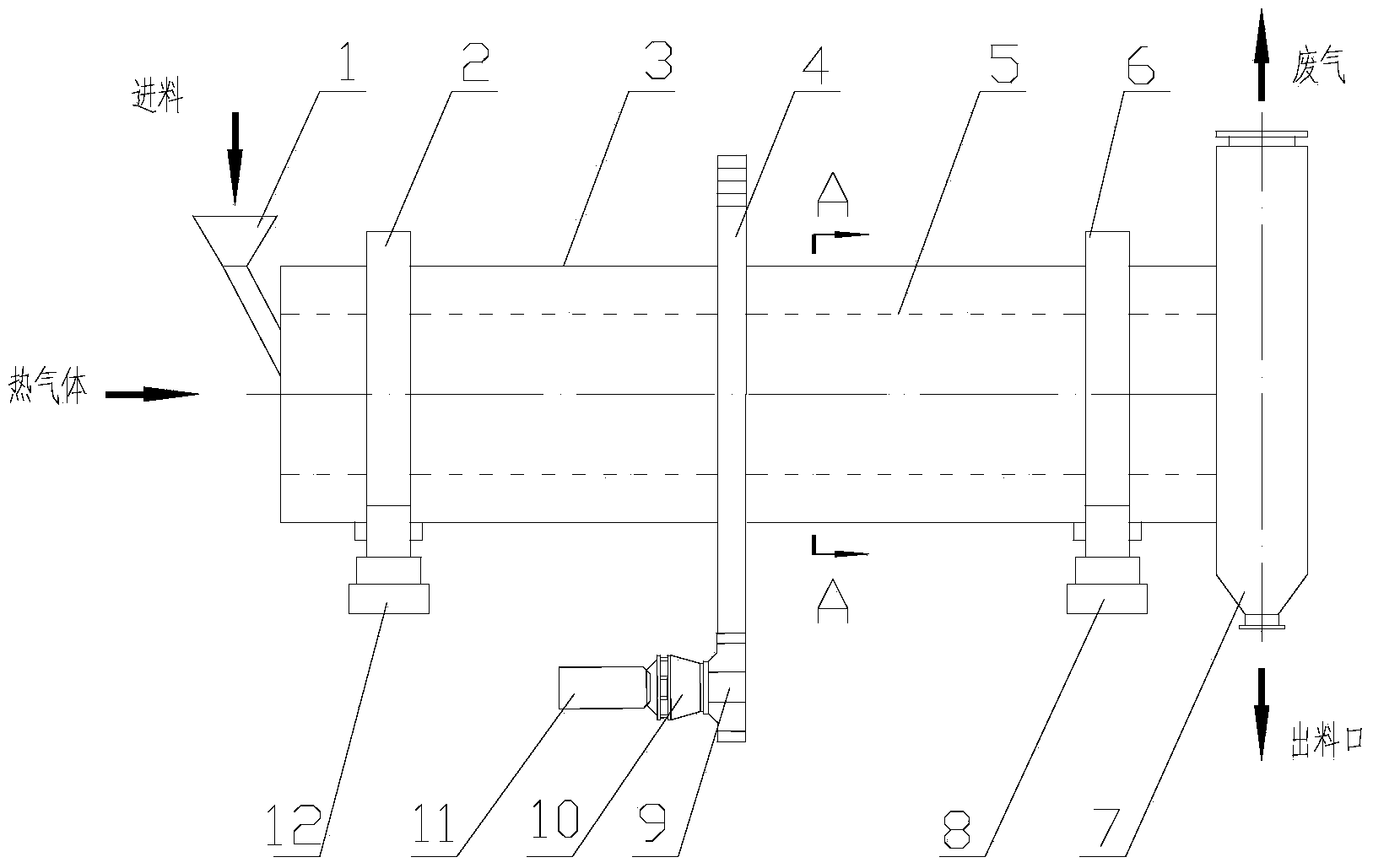

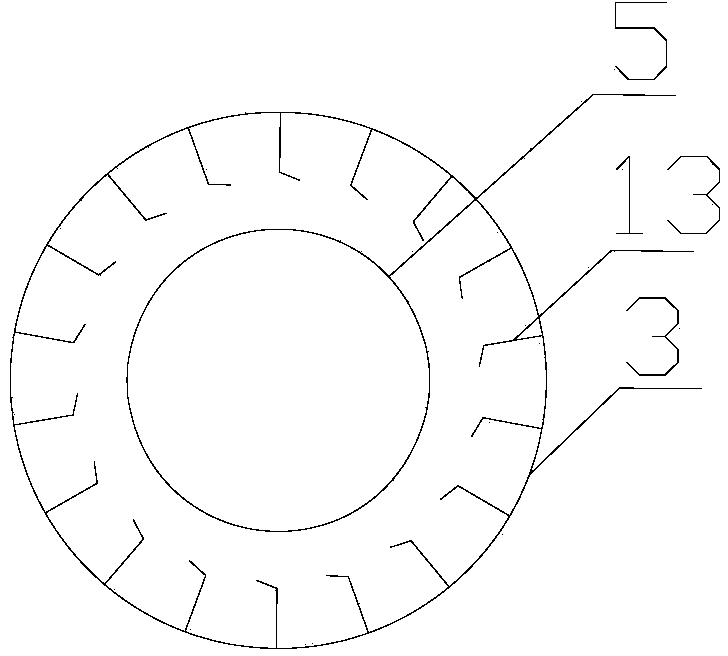

[0011] like figure 1 As shown, the rotary drum dryer with built-in screen according to the present invention includes a feeding port 1, a cylinder body 3, a drum screen 5, a lifting plate 13, a motor 11, a reducer 10, a coupling 9, Transmission gear 4 , front roller ring 2 , rear roller ring 6 , front roller 12 , rear roller 8 and discharging device 7 . The drum screen 5 is installed in the inner cavity of the cylinder body 3. The outer wall of the cylinder body 3 is provided with a transmission gear 4, a front roller ring 2 and a rear roller ring 6. The cylinder body 3 is supported by the front roller ring 2 and the rear roller ring 6. On the front supporting wheel 12 and the rear supporting wheel 8, the transmission gear 4 is connected to the motor 11 through the coupling 9 through the reducer 10, the lifting plate 13 is even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com