Wavefront phase sensor based on self-adaptive optical fiber coupler array

An optical fiber coupler and wavefront phase technology, applied in the field of optical engineering, can solve the problem of inability to directly measure the wavefront phase, and achieve the effect of manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

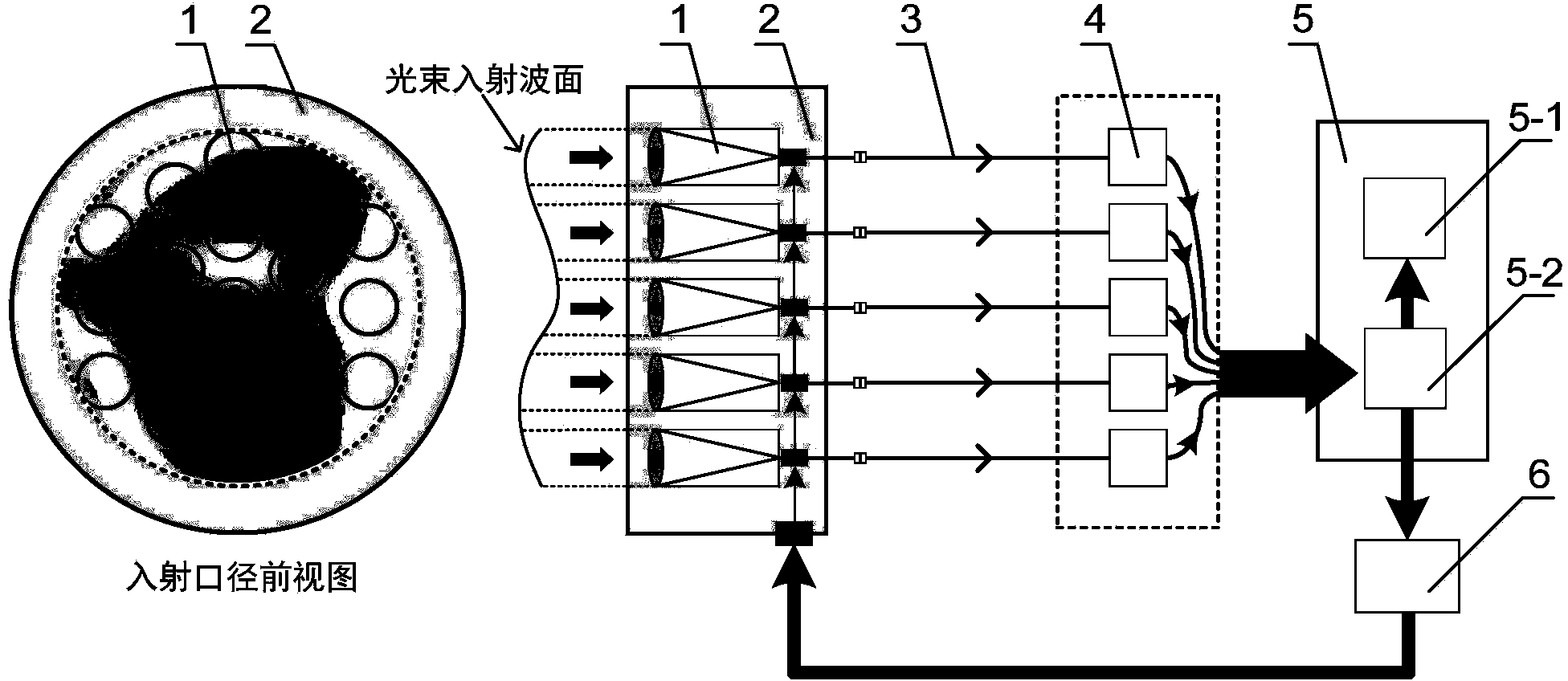

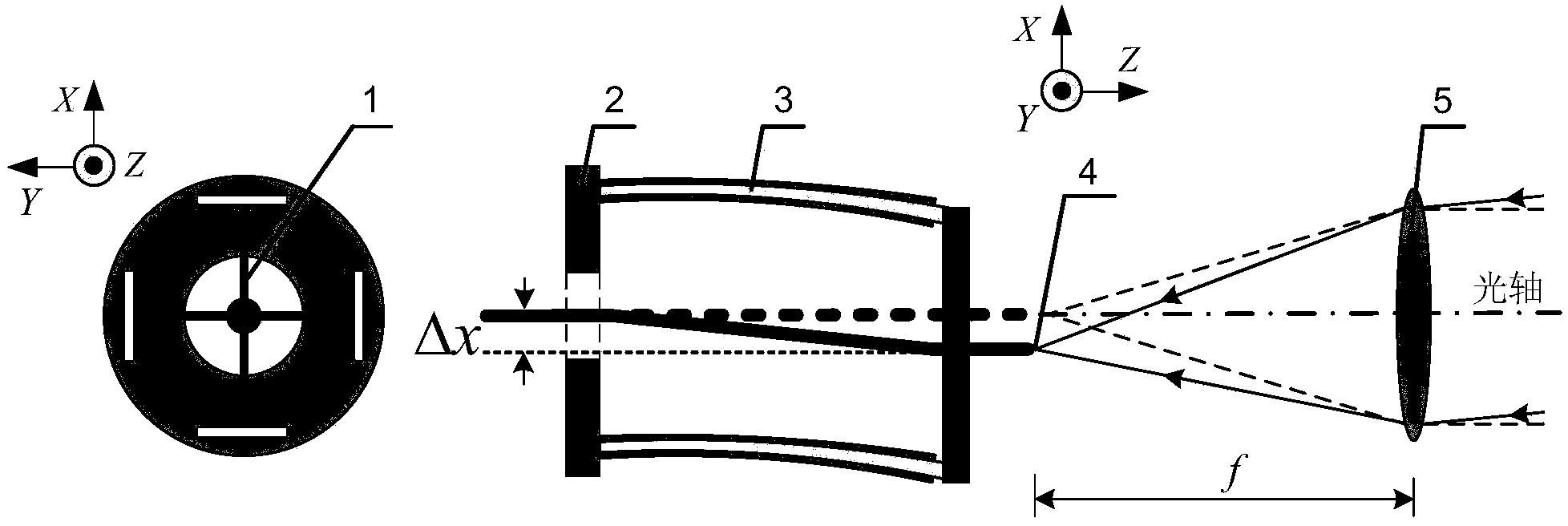

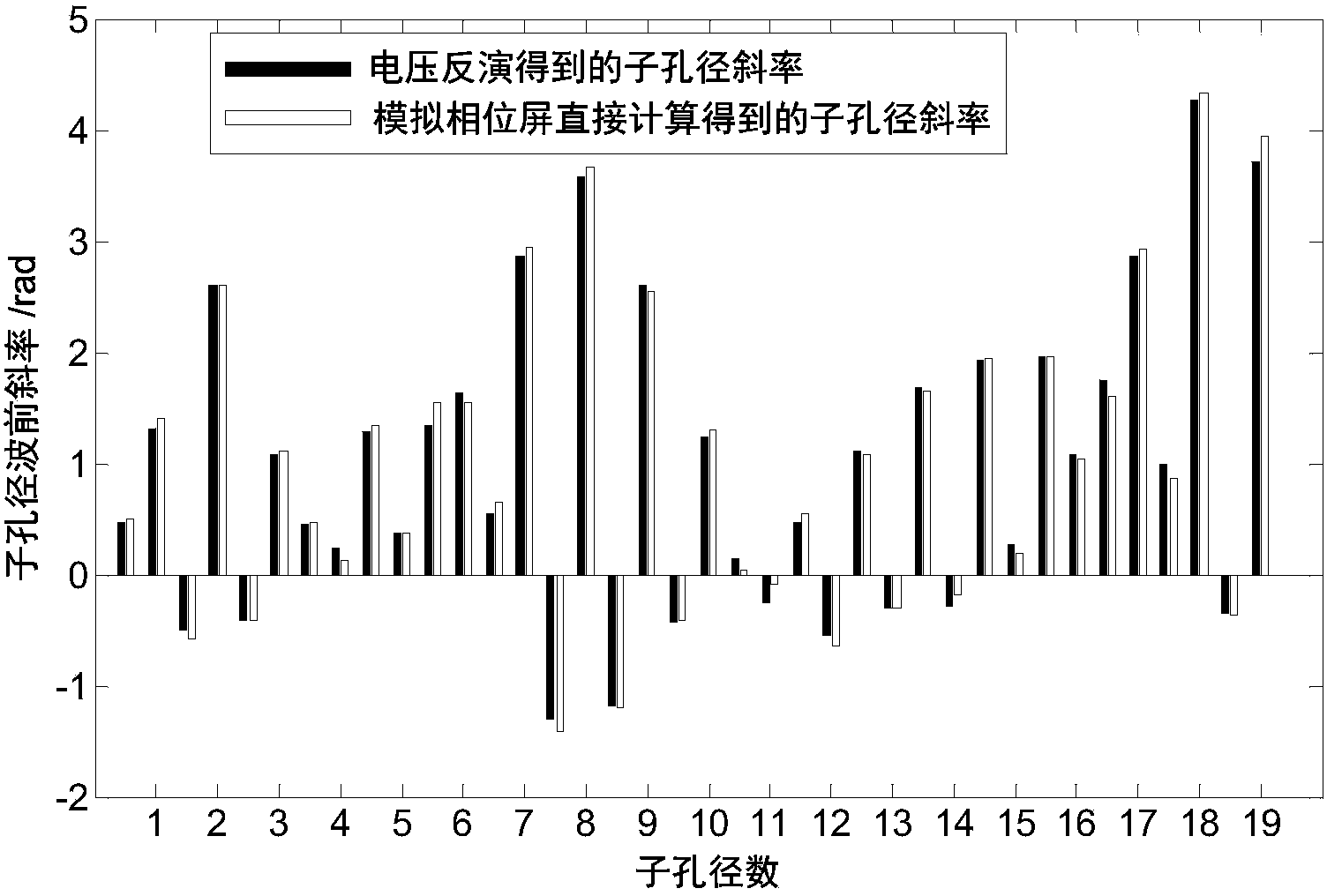

[0028] Such as figure 1 As shown, a wavefront phase sensor based on an adaptive fiber coupler array in this embodiment consists of an array of adaptive fiber couplers 1, a coupler integration device 2, an energy transmission fiber 3, 4 groups of photodetectors, and a control platform 5 and a multi-channel high-voltage amplifier 6 . Wherein, the control platform 5 further includes a wavefront reconstruction module 5-1 and a performance index parallel optimization module 5-1. The array of adaptive fiber couplers 1 is hexagonal close-packed, and the number of units is nineteen.

[0029] Such as figure 1 As shown, the connection relationship of each component in the wavefront phase sensor based on the adaptive fiber coupler array in this embodiment is: the spatial light beam is coupled into the single unit whose end face is located on the focal plane o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com