Test device used for testing resistance reduction performance of antifouling coating

A test device and technology of antifouling coating, applied in measurement device, fluid dynamics test, testing of machine/structural components, etc. High cost, uncertain sailing power or fuel consumption, etc., to achieve the effect of saving research and development costs, saving fuel consumption, and reducing uncontrollable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

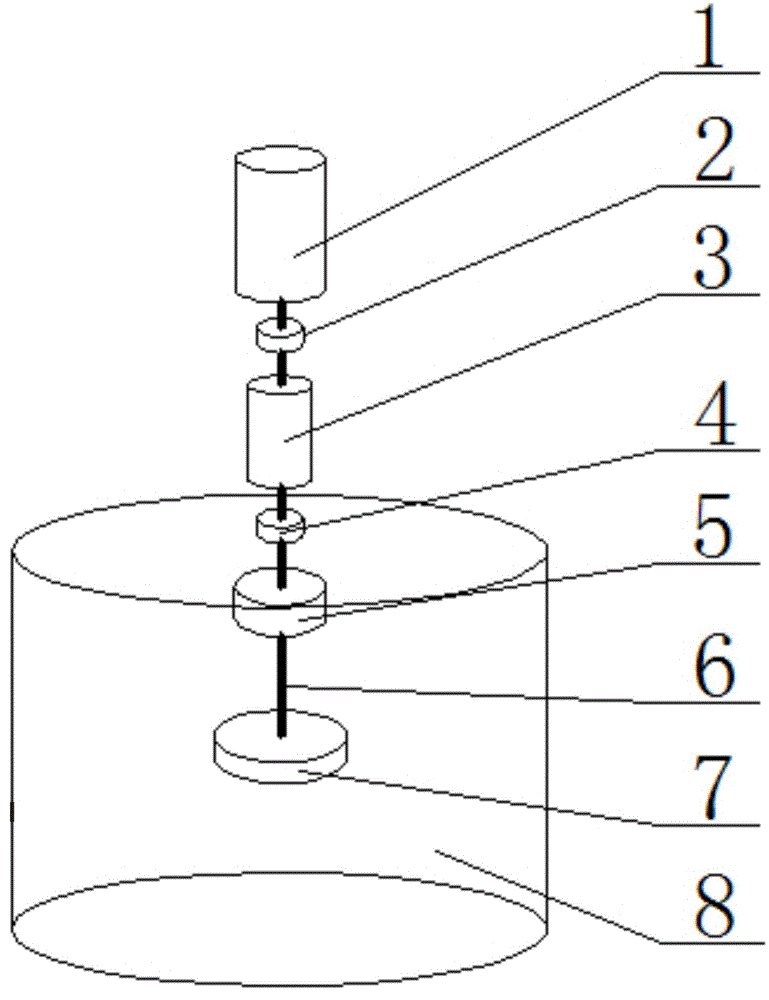

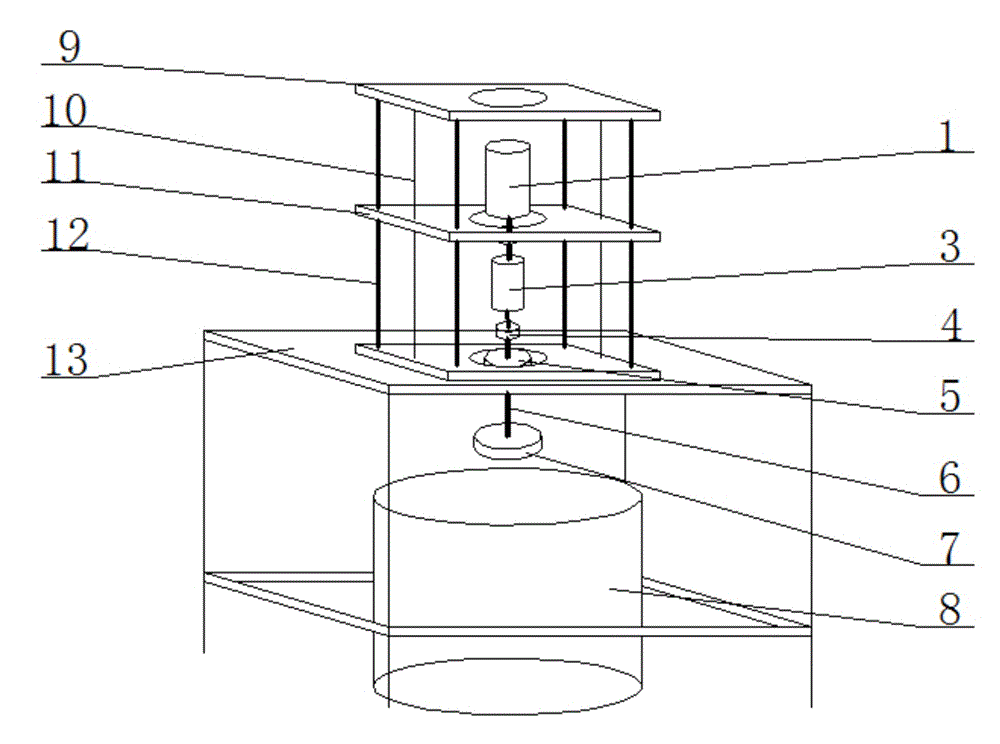

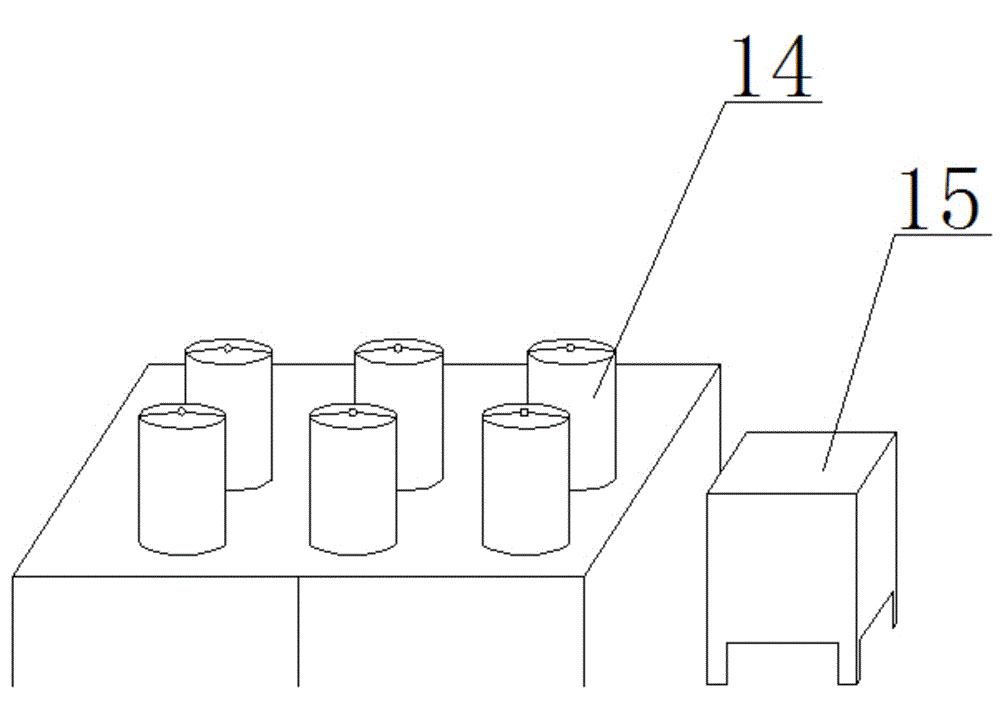

[0027] The working principle of the present invention is to use a motor to drive the sample to rotate, and after reaching a certain speed to form a turbulent state, a precision torque sensor is used simultaneously to measure the torque of the sample when the sample rotates at a constant speed under the turbulent state, and the torque is converted into an antifouling coating. The frictional resistance of the coating and the seawater interface, combined with the navigation simulation test, and comparing the resistance change of the coating at the same speed before and after seawater scouring, can measure and evaluate the resistance reduction performance and resistance reduction rate of the antifouling paint.

[0028] As shown in the figure, the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com