Particle field measurement device and measurement method based on digital micromirror plane structured light illumination

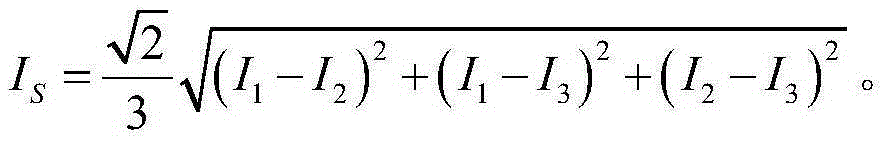

A technology of planar structured light and particle field, which is applied in the direction of analyzing materials and instruments, can solve the problems of system phase shift instability and cumbersome calibration, and achieve avoiding the optical path debugging process, improving phase shifting accuracy, and high-speed and stable particle field measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation examples of the present invention will be described in detail below in conjunction with the accompanying drawings.

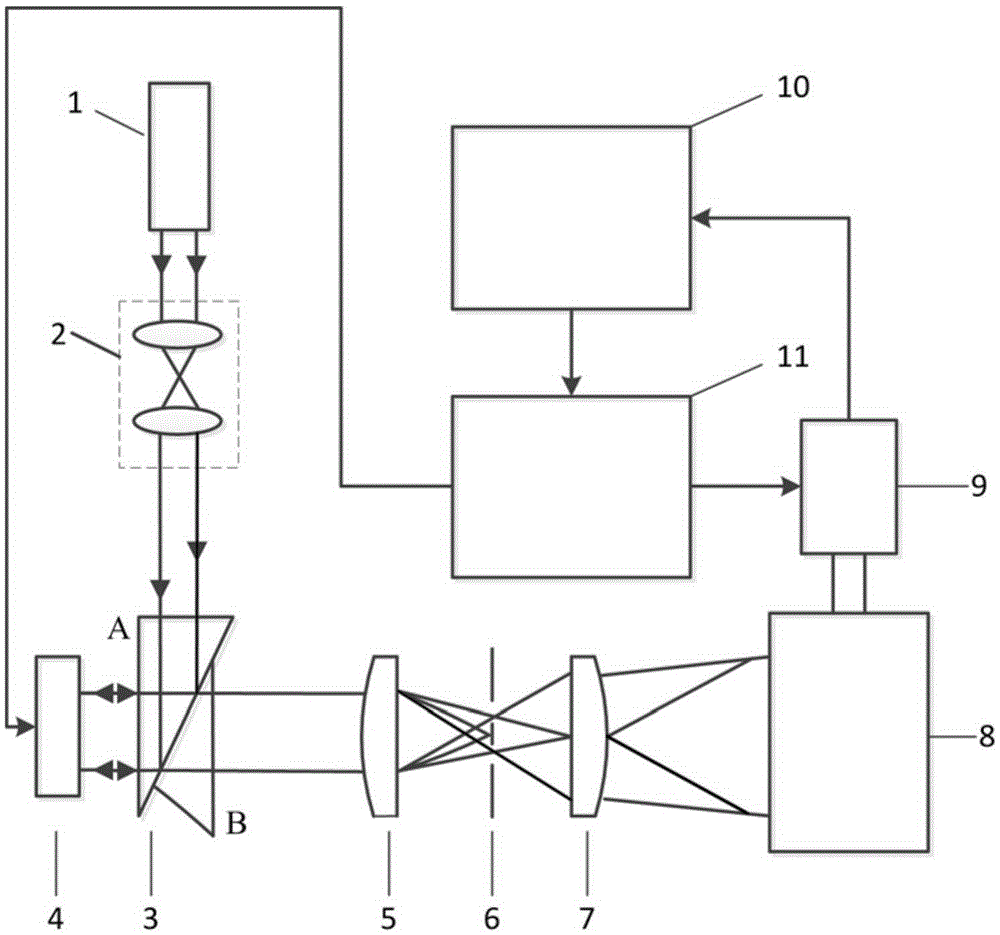

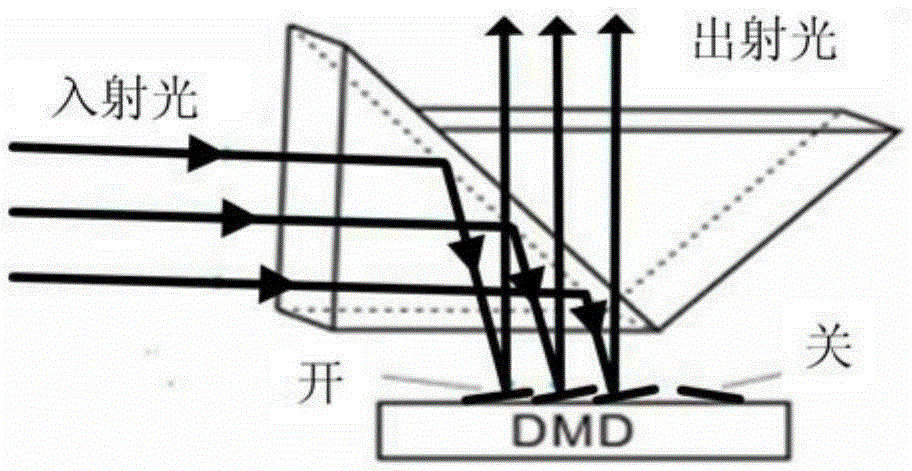

[0016] The device of the present invention comprises: a light source 1, a collimating beam expander system 2, a total internal reflection prism 3, a DMD4, a first cylindrical lens 5, a filter 6, a second cylindrical lens 7, a particle field 8, an image sensor 9, Computer 10 and synchronous controller 11, wherein the light source 1 is a laser with a wavelength of 532nm, the focal length of the first cylindrical lens 5 is 50mm, the focal length of the second cylindrical lens 7 is 500mm, and the digital one-dimensional periodic grating generated by DMD4 is periodic It is a binary one-dimensional periodic grating of 10 μm; DMD4 is located on the front focal plane of the first cylindrical lens 5, the total internal reflection prism 3 is located between DMD4 and the first cylindrical lens 5, and the filter 6 is located on the first cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com