Backlight testing method for electroless copper plating

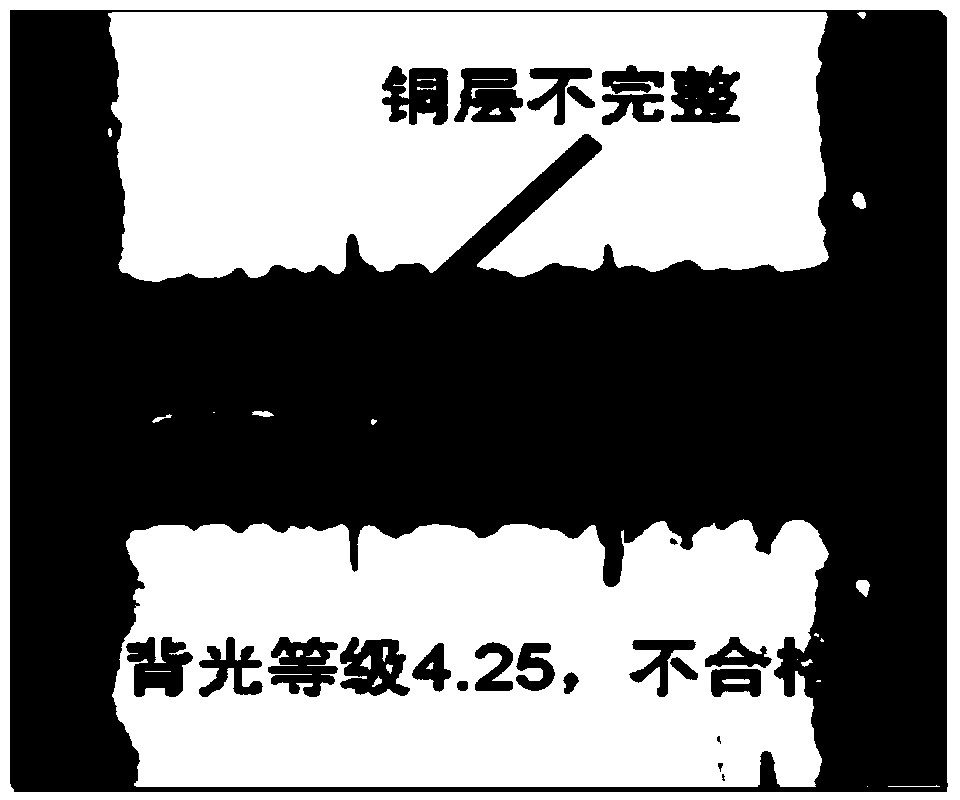

A technology of backlight testing and electroless copper deposition, which is applied in measuring devices, scientific instruments, and material analysis through optical means, etc., and can solve the problem of backlight test printed board thickness, number of layers, aperture, number of holes, and backlight level that are not specified in detail. Unqualified, inconsistent backlight samples, etc., to reduce the phenomenon of unqualified backlight inspection, achieve standardization, and improve the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0038] see figure 1 , figure 2 , Figure 5 to Figure 7 , the present invention is a kind of electroless copper backlight test method, and its test process is: make standard backlight test piece → electroless copper → potting of backlight test hole → grinding → test;

[0039] 1) Make a standard backlight test piece

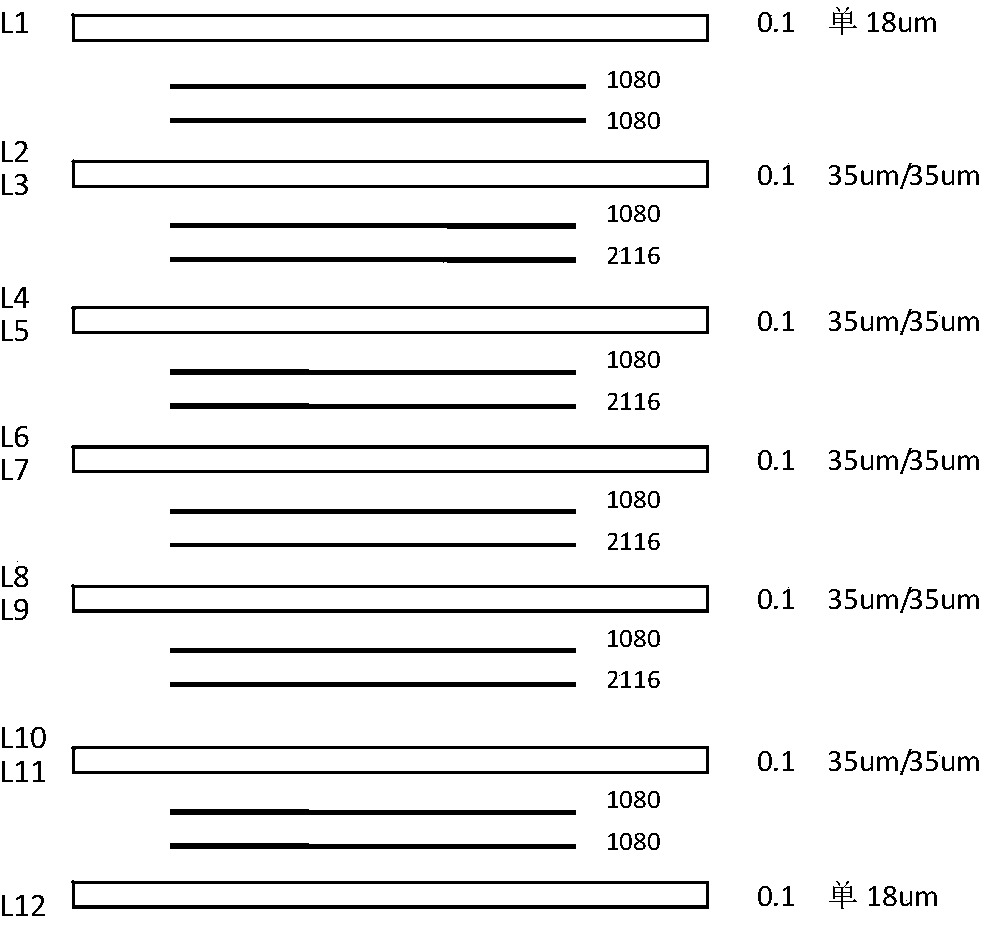

[0040] A) Use an etching machine to remove the copper foil on the surface of the copper-clad epoxy resin glass cloth laminate, and press it into a 12-layer backlight standard film with a thickness of 2.0mm using the lamination pattern;

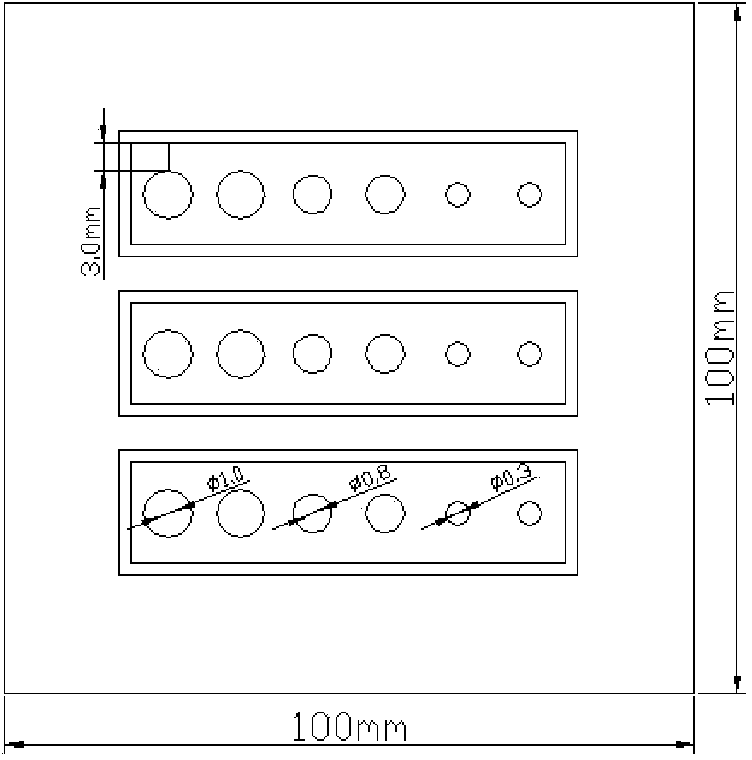

[0041] B) Two groups of backlight test holes with diameters of 0.3mm, 0.8mm and 1.0mm are processed by a CNC drilling machine on the backlight standard sheet obtained in step A);

[0042] C) Process the backlight standard sheet into a standard backlight test sheet with a size of 100mm×100mm by using a CNC milling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com