Hydrocracking catalyst and preparation and application thereof

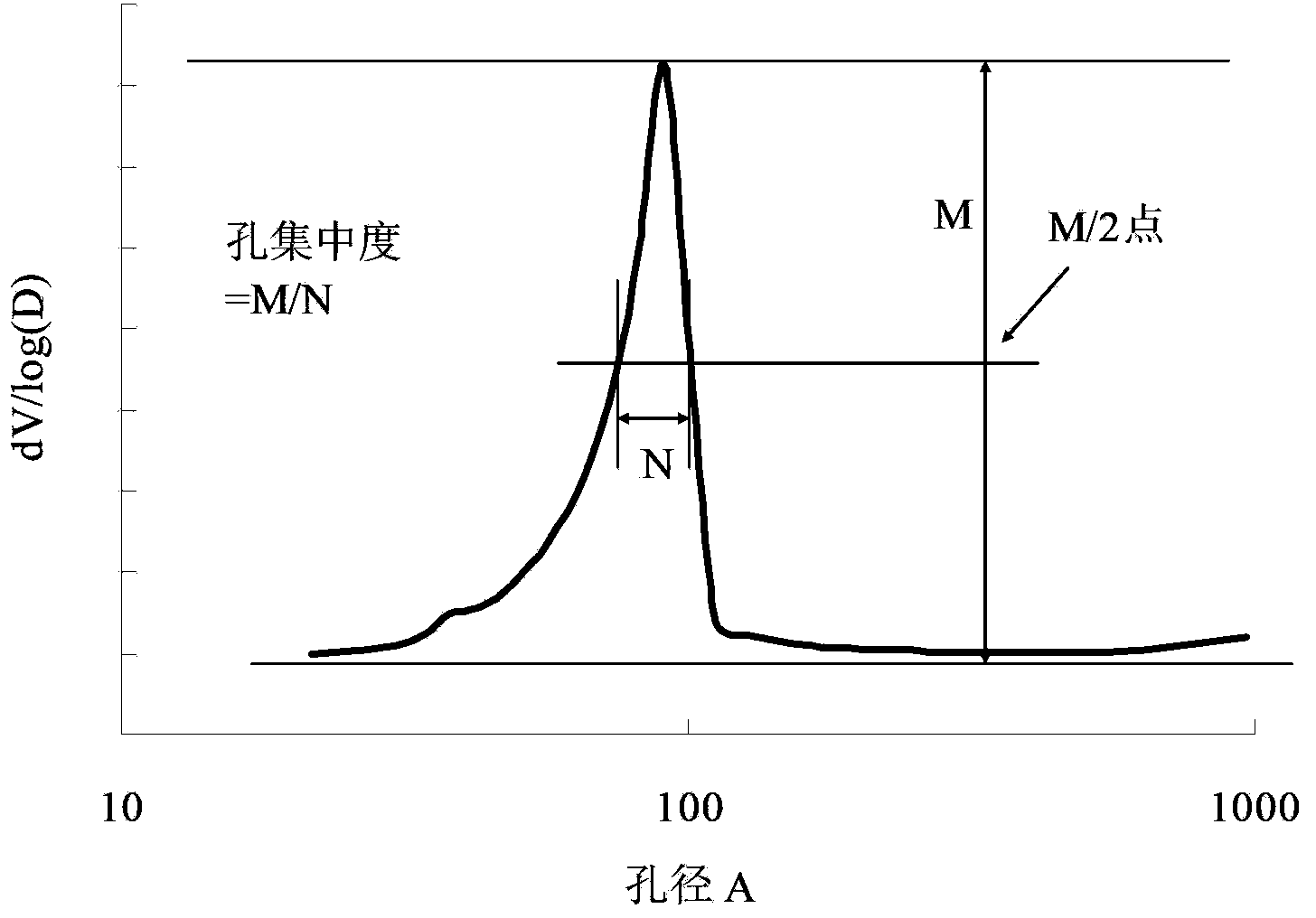

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems to be further improved, and achieve high catalytic activity, middle distillate selectivity, and high pore size. The effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027]According to the catalyst preparation method provided by the present invention, the preparation method of the support includes the following steps: (1) mixing the precursor of the heat-resistant inorganic oxide, the Y-type molecular sieve and the molecular sieve with the MFI structure, the peptizer and water to provide the raw material ; (2) feeding the raw materials into an extruder and extruding after kneading in the extruder to obtain a molded body; (3) roasting the molded body to obtain the carrier , wherein, the temperature of the molded body at the outlet of the extruder is 40-150°C.

[0028] In the process of extruding raw materials with an extruder to obtain a molded body, the extrusion temperature is usually not particularly controlled (usually room temperature or lower than 40 ° C), but the inventors of the present invention have found in the course of research that Making the temperature of the molded body at the outlet of the extruder 40-150° C. can make the ...

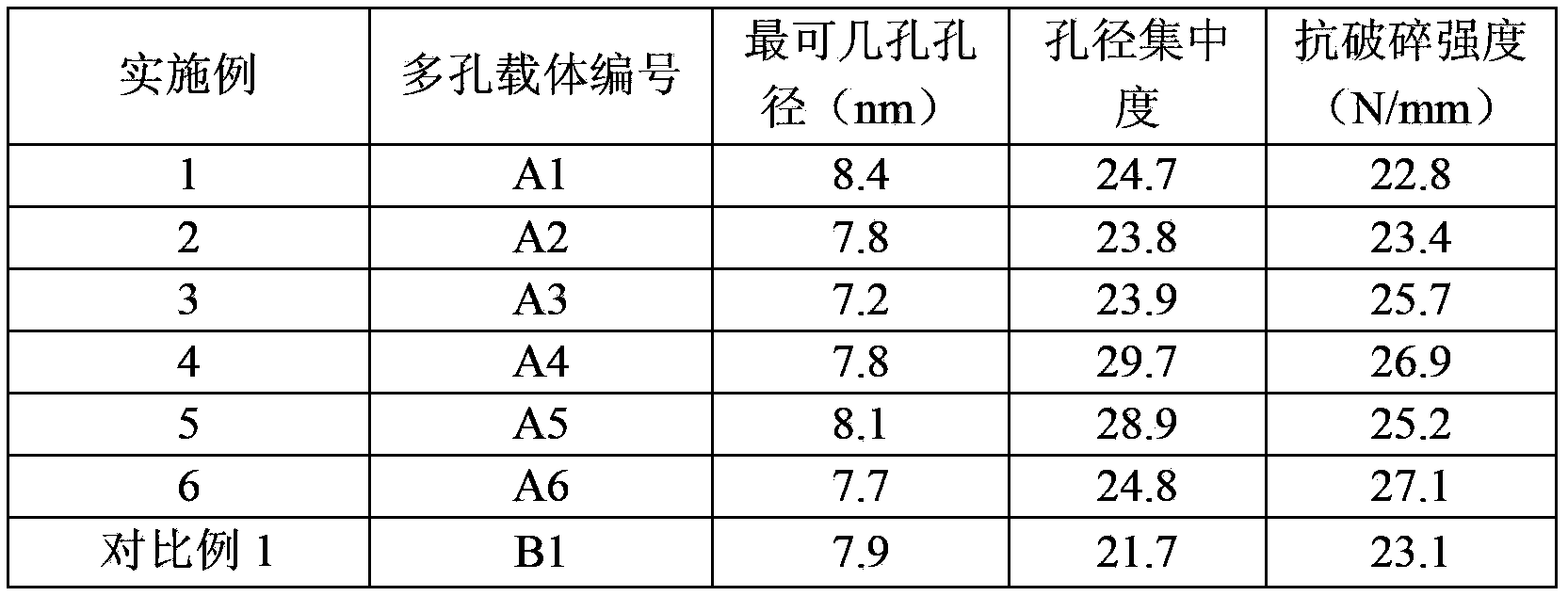

Embodiment 1

[0089] Take SB powder (taken from Changling Catalyst Factory, produced by SASOL Company, relative crystallinity 95.4%, grain size 49.0nm, dry basis content is 75%, the same below) 84.0g, Siral40 powder (commercially purchased from SASOL Company, oxidized Silicon content is 40%, dry basis content is 77.5%) 25.8g, Y-type molecular sieve A (unit cell constant , crystallinity 81.4%, Na 2 0.02%, dry basis 86%, the preparation method is referring to ZL01118446.9, embodiment 6, molecular sieve I, the same below) 18.1g, ZRP-5 molecular sieve A (taken from Changling Catalyst Factory, containing rare earth, has MFI structure, The silicon-aluminum ratio is 60.6, the dry basis content is 83%, the same below) 2.4g, add 3g of safflower powder and dry mix evenly to obtain a dry powder. Add 3 mL of concentrated nitric acid into a beaker filled with 90 mL of deionized water, and mix well to obtain an acid solution. Mix the acid liquid and dry powder, and stir evenly to obtain the raw materi...

Embodiment 2

[0091] Take CL powder (taken from Changling Catalyst Factory, relative crystallinity 98.1%, grain size 33.0nm, dry basis content 71%, the same below) 45.1g, Siral30 powder (commercially purchased from SASOL company, silicon oxide content is 30 %, the dry basis content is 76%, the same below) 46.6g, Y-type molecular sieve C (unit cell constant , crystallinity 85.7%, Na 2 O0.032%, dry basis 85%, the preparation method sees ZL01118446.9, embodiment 3, molecular sieve C) 30.1g, ZRP-5 molecular sieve B (taken from Changling Catalyst Factory, contains rare earth, has MFI structure, silicon aluminum ratio 35.6, the dry basis content is 81%, the same below) 9.9g, add 3g of scallop powder and dry mix evenly to obtain dry powder. Add 1.5mL of concentrated nitric acid into a beaker containing 87mL of deionized water, and mix well to obtain an acid solution. Mix acid liquid and dry powder, and stir evenly to obtain the raw material mixture for extrusion, send the obtained mixture into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com