Continuous production and dip-lifting film coating device and application method thereof

A film coating device, dipping and pulling technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of non-continuous production, low control accuracy, uneven thickness, etc., and prevent the slurry from being uneven. Uniform, uniform film thickness, adjustable film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

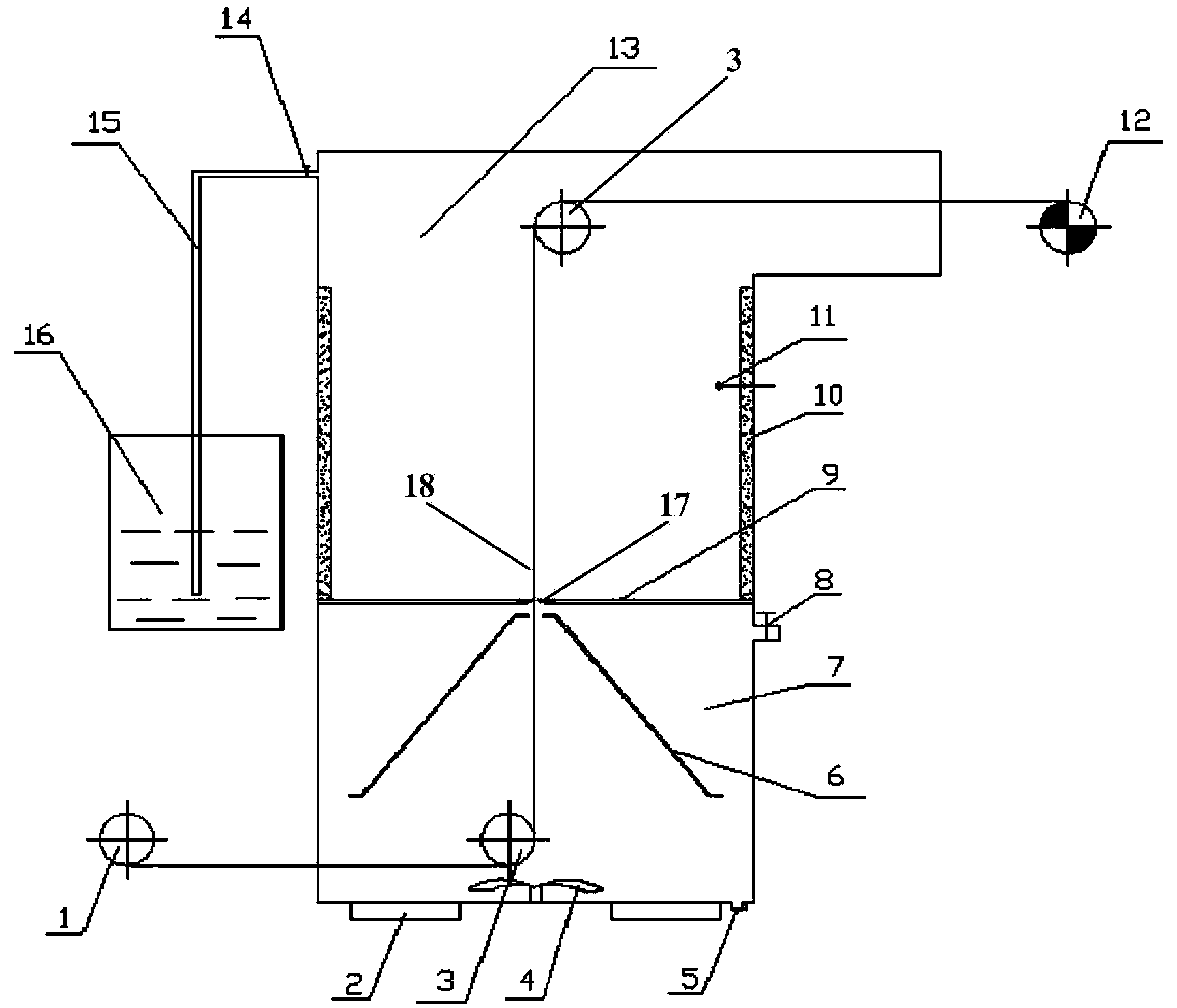

[0024] The continuous production dipping and pulling film coating device of the present invention mainly includes a base, a coating film chamber, a film drying chamber, a transmission device, and a solvent recovery device, wherein: the film coating chamber is provided with a stirring paddle for stirring the slurry, and the thickness of the slurry can be Knife adjustment, slurry flow baffle, and base cloth unwinding through rollers to pull film-making rollers, slurry inlet, and outlet; the film drying chamber is equipped with a heating plate, temperature sensor, and exhaust port ; The transmission device includes a speed-adjustable traction device, and the speed-adjustable traction device drives a reversible, speed-controllable roller; the solvent recovery device is inserted into the drying film chamber through the air duct.

[0025] Such as figure 1 As shown, the continuous production dipping and pulling coating device of the present invention consists of base cloth unwinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com