Disassembling and vehicle shell crushing assembly line for scraped car

A scrapped car and assembly line technology, applied in solid waste removal, grain processing, etc., can solve the problems of lack of equipment, no equipment configuration, increased transshipment costs, etc., and achieve the effect of reducing labor intensity and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

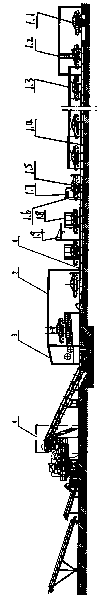

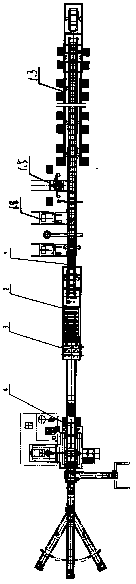

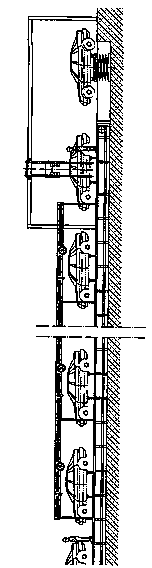

[0034] See attached Figure 1-8 , The present invention relates to a scrapped car dismantling-car shell crushing line, which is mainly composed of a dismantling line 1, a lifting conveying discharge machine 2, a pre-shredder 3 and a crushing line 4.

[0035] The dismantling line 1 is provided with a lift 1.1, a lifting conveyor 1.2, a lighting and power configuration support 1.3, a chain conveyor 1.4, a mobile car turning machine 1.5, a suspension slewing bracket 1.6, a spring balancer 1.7, a mobile Type car lift 1.8, crane 1.9, etc.; pre-crusher 3 is set at the rear end of dismantling line 1, and pre-crusher 3 is provided with a feeding raceway; lifting conveyor discharge machine 2 is set across the dismantling line 1 and the pre-crusher 3 junction area; the crushing line 4 is set behind the pre-crusher 3, and the crushing line 4 is equipped with a crushing host 4.1, a feed conveyor 4.2, a discharge conveyor 4.3, a sorting conveyor 4.4, Sorting machine 4.5, dust removal and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com