Method for salvaging sunken ship by adopting rubber air bag

A rubber airbag and airbag technology, applied in ship salvage, ship, transportation and packaging, etc., can solve the problems of cumbersome and inconvenient bundling operation, long process of water filling and drainage, complex structure of steel buoy, etc., and achieve good installation Operability, saving construction, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

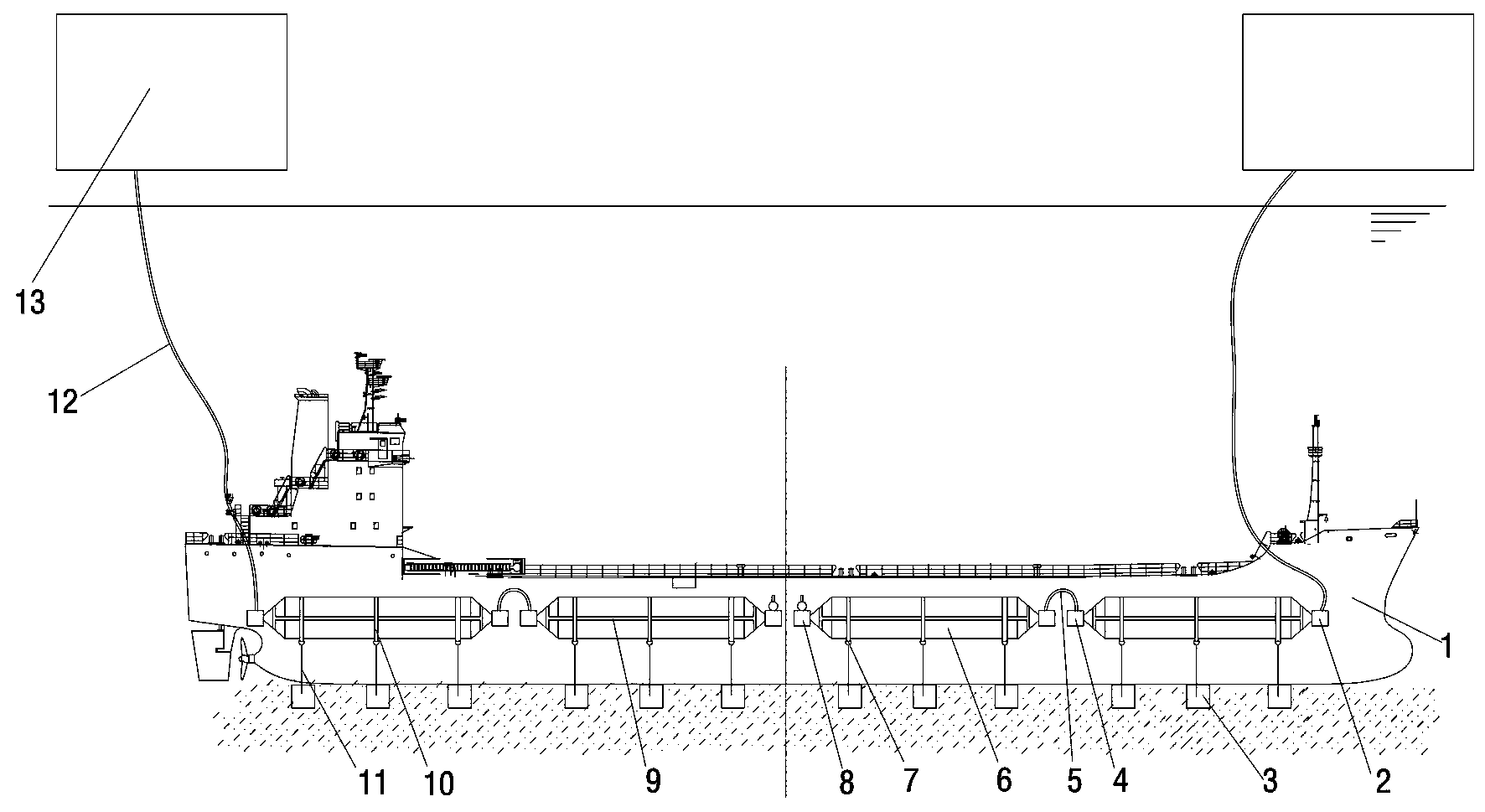

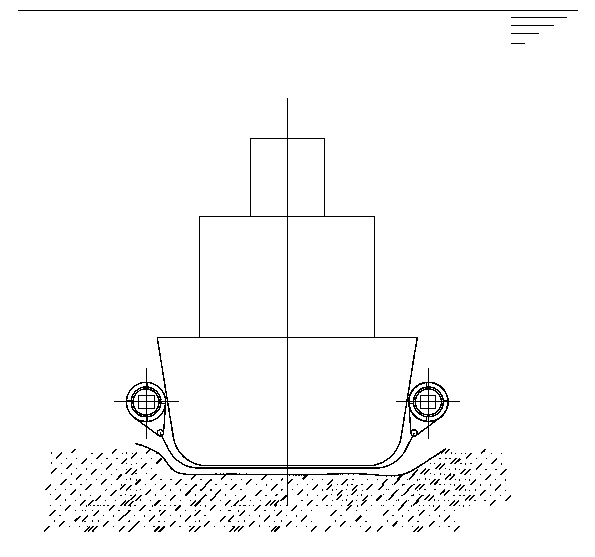

[0027] Accompanying drawing is an embodiment of the present invention, present embodiment is specifically described in conjunction with accompanying drawing,: comprise by the ship bottom part of shipwreck 1 in underwater seabed silt, open the jack at the ship bottom by predetermined position by means such as drilling tunnels etc. Hole 3, the steel cable 11 that passes through in it is used for enclosing the bottom of the ship, and a suitable number of rubber airbags 6 are symmetrically arranged on the left and right sides of the shipwreck 1, and the rubber airbags 6 are installed on the outside made of longitudinal belts 9 and transverse belts 10. Net cover, the bottom of the horizontal band 10 of the body installs the steel living chain ring 7, which connects the heavy steel cable 11 in the heavy hole 3, and realizes the symmetrical connection of the left and right airbags of the ship's side, so that when the force is lifted, the airbags are connected to each other. Lifting fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com