Special functional urea formaldehyde fertilizer for garlic and preparation method thereof

A functional and special fertilizer technology, applied in the field of urea-formaldehyde functional garlic special fertilizer and its preparation, to achieve the effects of not destroying the ecological environment, reducing the amount of fertilizer, and lasting fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

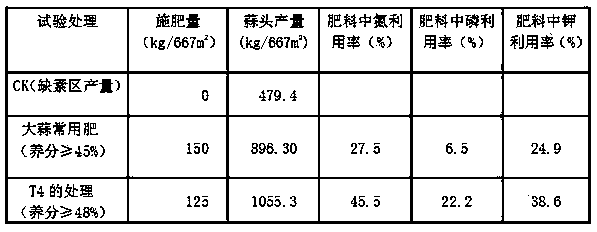

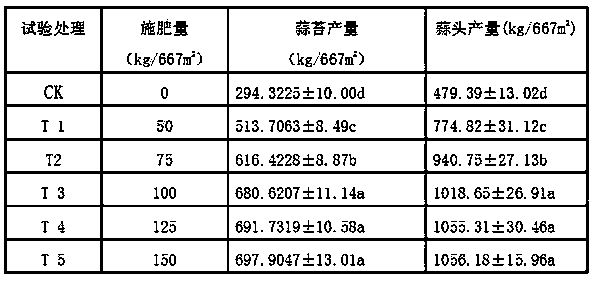

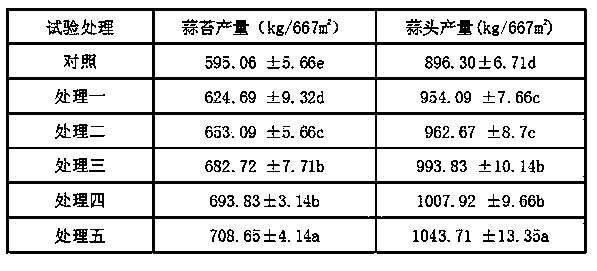

Examples

Embodiment 1

[0018] First, fully mix 2kg of polyaspartic acid with 325kg of urea, 240kg of monoammonium phosphate, 305kg of potassium chloride, 85kg of sulfur, 3kg of filler, etc., then pulverize and stir. Then add urea-formaldehyde solution spray (first inject the formaldehyde solution into the urea-formaldehyde preparation tank through the formaldehyde solution pump, after stirring, inject the molten urea with a concentration of 96.5% through the molten urine pump to fully mix it with the formaldehyde solution, and then add the concentration 50% NaOH solution, adjust the pH value of the mixture to 7.2; finally inject steam to raise the final temperature to 75°C. After 30-45 minutes of reaction, a urea-formaldehyde solution will be generated, of which 40kg of urea-formaldehyde), the material Mix and granulate in a drum granulator, dry through a drum dryer, and then pass through sieving and packaging to produce finished products. The product has a particle size (3.35mm-5.60mm) of 92%, smoo...

Embodiment 2

[0029] First, fully mix 4kg of polyaspartic acid with 339kg of urea, 227kg of monoammonium phosphate, 300kg of potassium chloride, 74kg of sulfur, and 6kg of filler, then pulverize and stir. Then add urea-formaldehyde solution spray (first inject the formaldehyde solution into the urine formaldehyde preparation tank through the formaldehyde solution pump, after stirring, inject the molten urea with a concentration of 96.5% through the molten urine pump to fully mix it with the formaldehyde solution, and then add the concentration 50% NaOH solution, adjust the pH value of the mixture to 7.2; finally inject steam to raise the final temperature to 75°C. After 30-45 minutes of reaction, a urea-formaldehyde solution will be generated (50kg of urea-formaldehyde). Mix and granulate in a drum granulator, dry through a drum dryer, and then pass through sieving and packaging to produce finished products. The product has a particle size (3.35mm-5.60mm) of 92%, smooth particles, strong cr...

Embodiment 3

[0032] Firstly mix 6kg polyaspartic acid with 356kg urea, 215kg monoammonium phosphate, 290kg potassium chloride, 64kg sulfur, etc., then pulverize and stir. Then add urea-formaldehyde solution spray (first inject the formaldehyde solution into the urine formaldehyde preparation tank through the formaldehyde solution pump, after stirring, inject the molten urea with a concentration of 96.5% through the molten urine pump to fully mix it with the formaldehyde solution, and then add the concentration It is 50% NaOH solution, adjust the pH value of the mixture to 7.2; finally inject steam to raise the final temperature to 75°C. After 30-45 minutes of reaction, a urea-formaldehyde solution will be generated, of which 60kg of urea-formaldehyde), the material Mix and granulate in a drum granulator, dry through a drum dryer, and then pass through sieving and packaging to produce finished products. The product has a particle size (3.35mm-5.60mm) of 92%, smooth particles, strong crush r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com