Method for controlling nitrogen content of molten steel in converter steel-making

A converter steelmaking and molten steel technology, applied in the manufacture of converters, etc., can solve the problems of difficult control of nitrogen addition and reduction of nitrogen absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

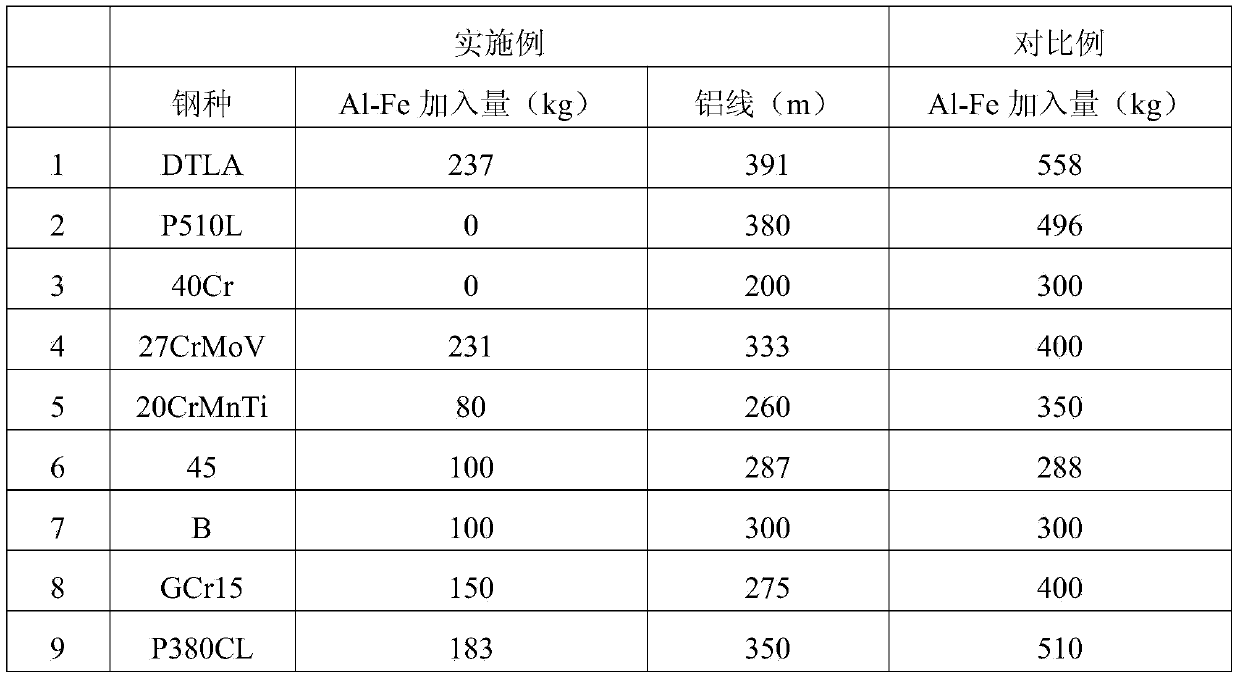

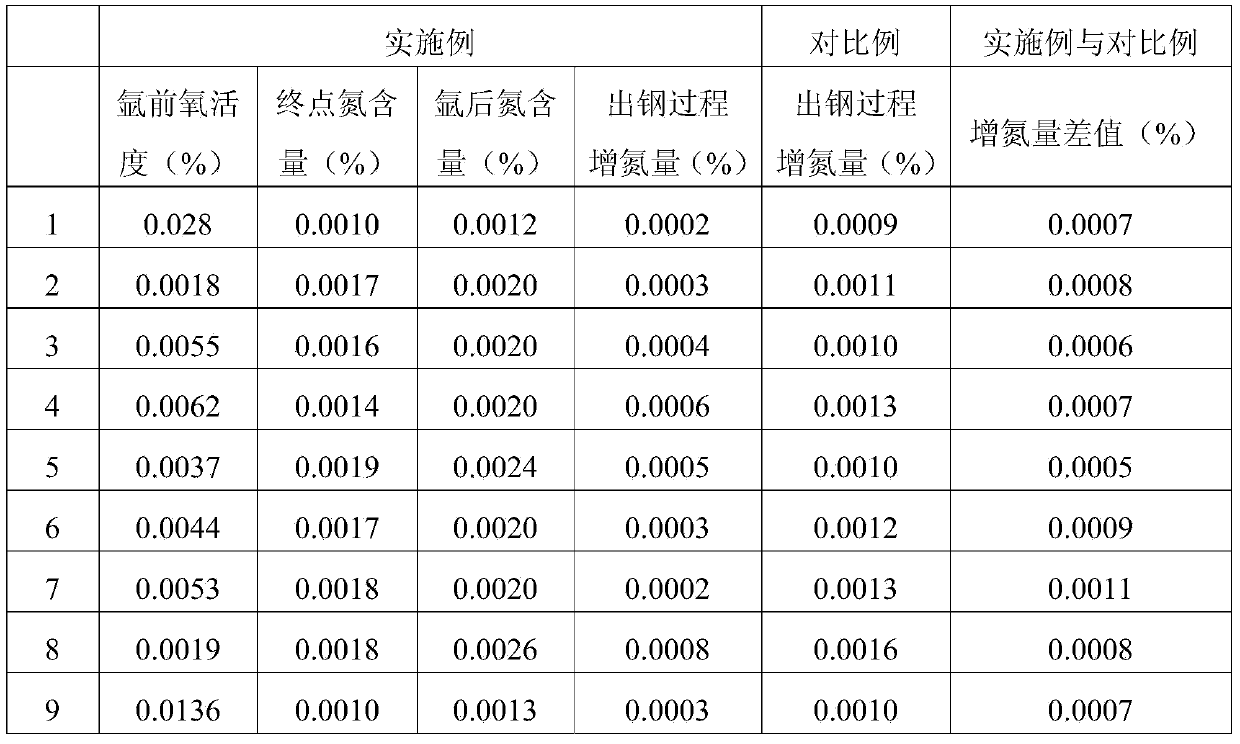

[0027] Production of DTLA steel. First, open the bottom of the ladle to blow argon before tapping. Then, add Al-Fe alloy deoxidizer (the weight of molten steel is 130t) in the ladle in the process of tapping, so that the oxygen content of molten steel after tapping remains on about 150ppm, thereby prevents molten steel from contacting nitrogen with air. Finally, deoxidize the molten steel in the ladle by feeding the aluminum wire (diameter of the aluminum wire is 10mm) at the wire feeding station so that the molten steel reaches the required oxygen content for pouring. The technological parameters of this process and the amount of nitrogen added in the tapping process are shown in Table 1 and Table 2.

Embodiment 2~9

[0031] The process flow of Examples 2-9 is the same as that of Example 1, and see Table 1 and Table 2 for the process parameters and the amount of nitrogen added in the tapping process. Wherein, the oxygen content of the tapped molten steel of the low alloy steel is kept at about 150 ppm, and the oxygen content of the tapped molten steel of the high alloy steel is kept at about 50 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com